Dissolved air tank with adjustable vapor liquid ratio

A technology of dissolved air tank and gas-liquid ratio, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of reducing air flotation effect, unsatisfactory treatment effect, and unsuitable impact of air flotation machine, so as to improve the efficiency of dissolved air. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

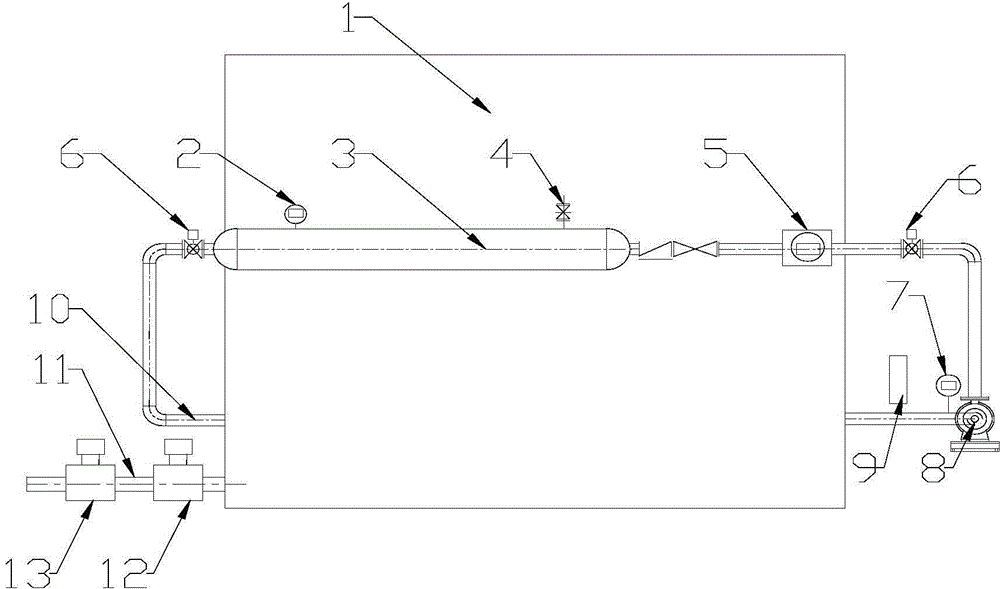

[0010] The present invention will be further described below in conjunction with accompanying drawing:

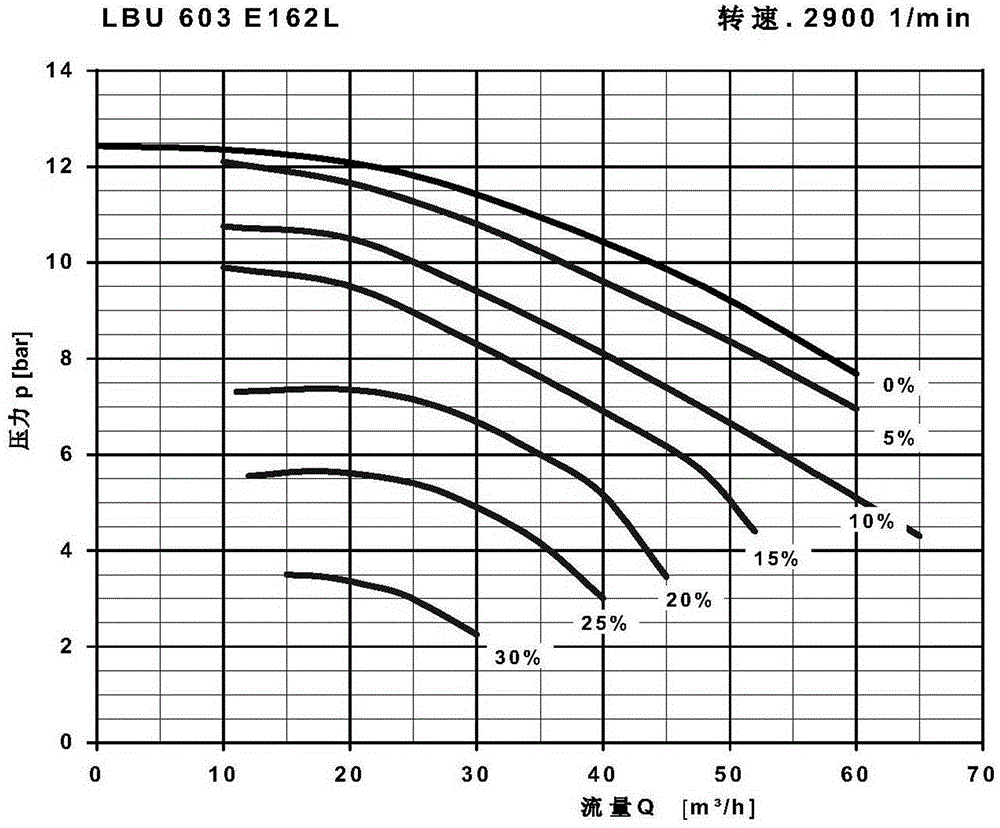

[0011] Depend on figure 1 As shown, the dissolved air tank with adjustable gas-liquid ratio includes an air flotation tank 1, the bottom of the water outlet part of the air flotation tank 1 is led out by a pipeline, and then connected in series with a dissolved air pump 8, an electric regulating valve 6, a circulating water flow meter 5, a gate valve, The check valve, the dissolved air tank 3, and the electric regulating valve 6 adjust the pressure and flow of the dissolved gas tank 3. The outlet side pipeline of the dissolved gas tank 3 is connected in series with an electric regulating valve 6 and then connected to the release pipe 10, which is located above the water inlet pipe 11. . The water inlet pipe 11 is connected in series with an online turbidimeter 13 and an inlet water flow meter 12 . The present invention sets the circulating water flow rate required by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com