Special roll surfacing welding machine

A special machine and roll technology, applied in the field of welding, can solve the problems that the roll rotation speed cannot be kept consistent, affect the quality of surface surfacing welding, and the body is bulky, etc., and achieve the effect of low cost, simple structure, and uniform rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

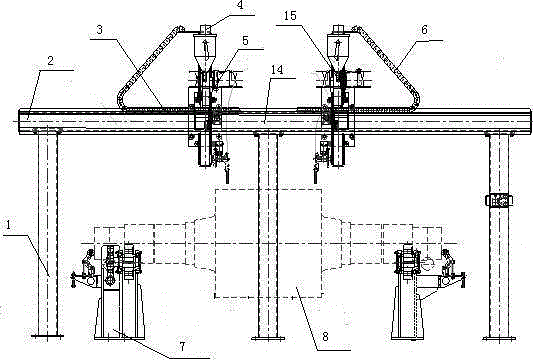

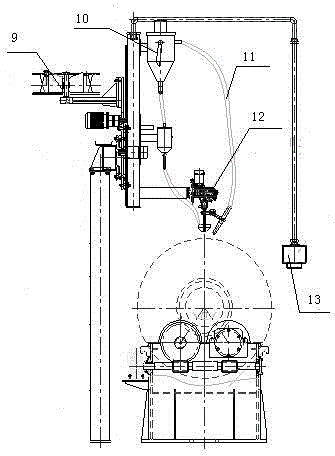

[0021] Such as figure 1 and figure 2 As shown, a roll surfacing machine includes a welding mechanism 15, a frame 14, a roller frame 7 and a welding torch moving mechanism. The welding mechanism 15 is installed on the frame 14, and the roller frame 7 is placed under the frame 14. There are two welding mechanisms 15 and roller frames 7, which are symmetrical along the longitudinal centerline of the frame 14.

[0022] The welding mechanism 14 includes a welding head 12 , a flux funnel 10 , a wire reel 9 and a control box 13 , and the flux funnel 10 is connected to the welding head 12 through a delivery pipe 11 .

[0023] The welding torch moving mechanism includes a welding torch lifting mechanism 4, a welding torch traveling mechanism 5, a cable towline 6 and a walking platform 3. The walking platform 3 is arranged on the surface of the frame 14, and the walking platform 3 is connected to the welding lifting mechanism 4 through the cable towline 6. The frame 14 is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com