Coal milling method adopting medium speed coal mill as well as used coal mill

A coal mill, medium-speed technology, applied in the direction of dryers, grain processing, lighting and heating equipment, etc., can solve the problems of grinding roller wear, coal quality is not loose, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

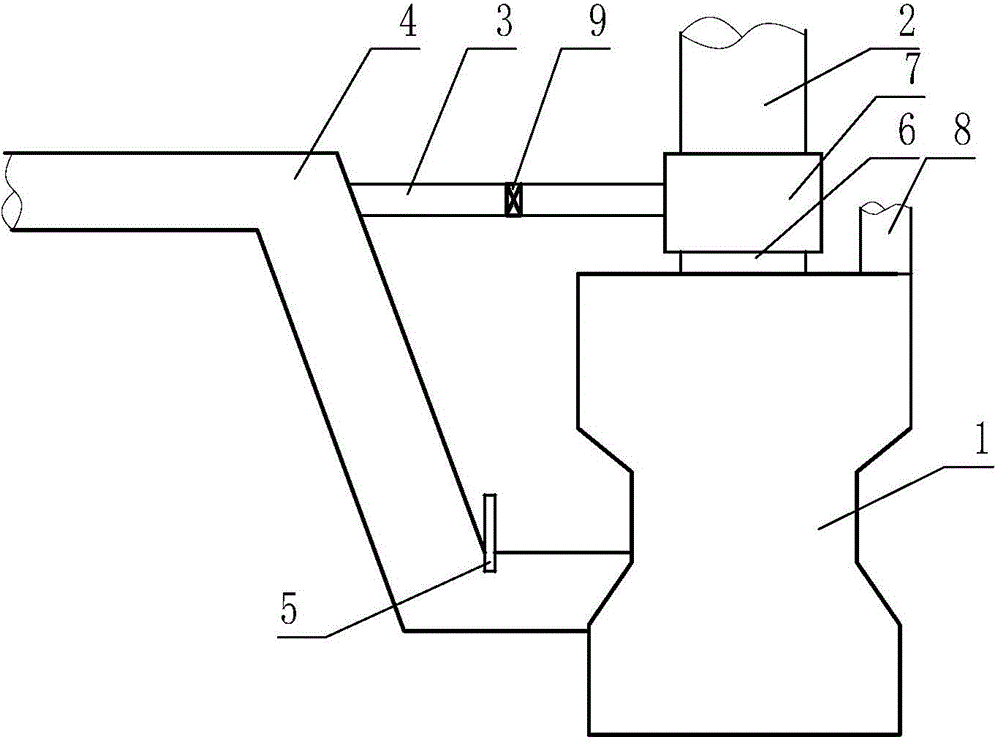

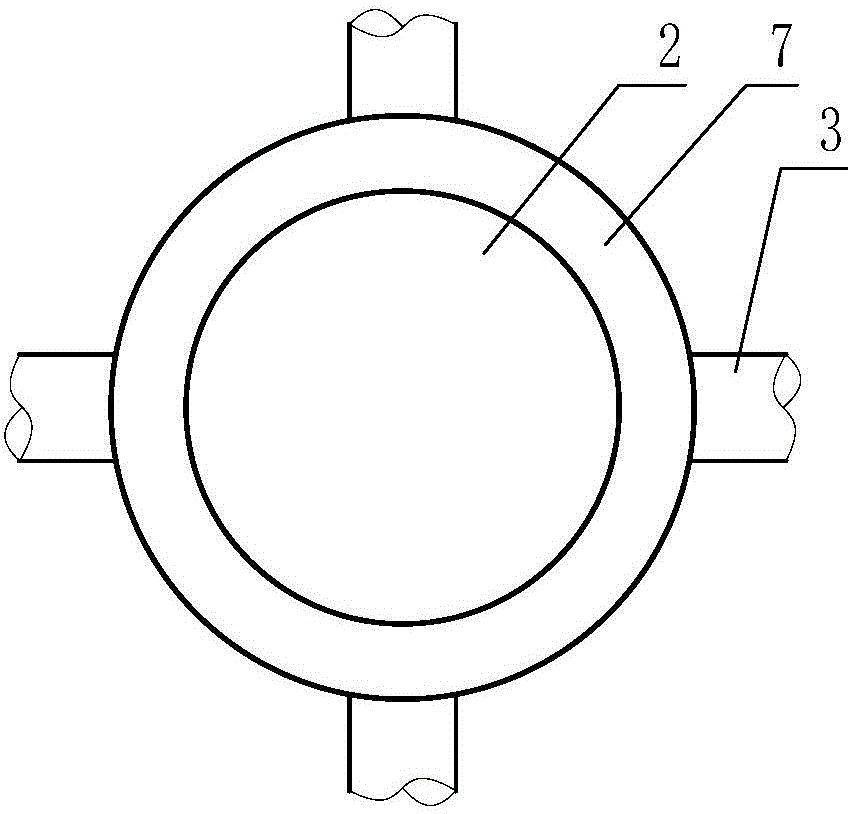

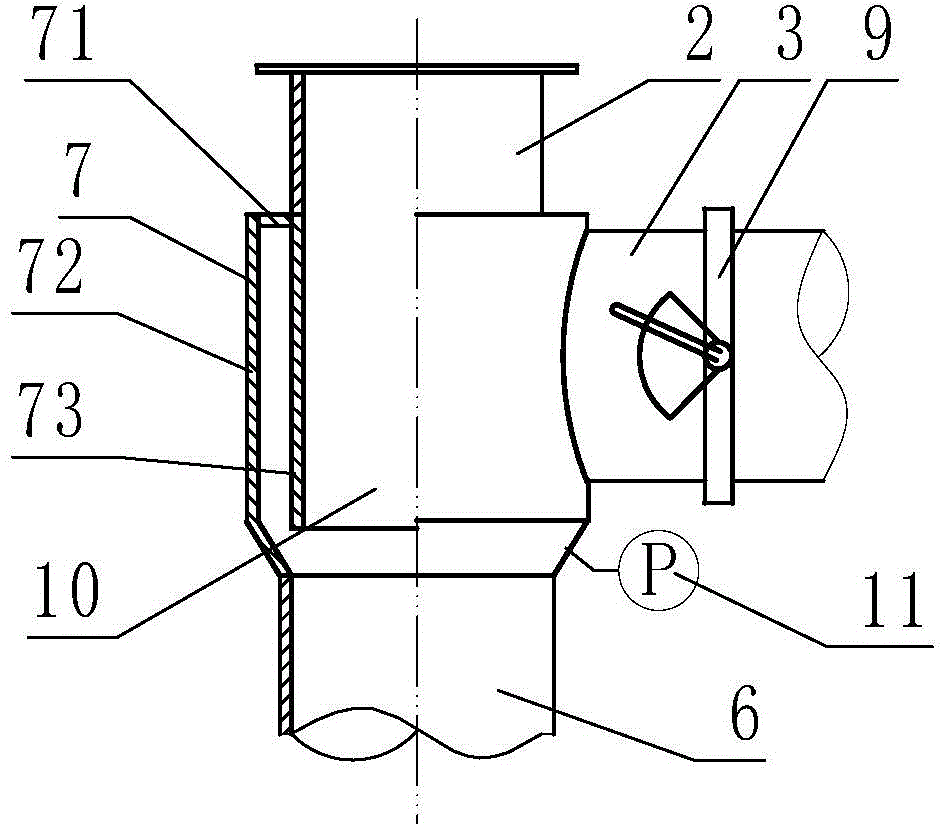

[0024] Embodiment 1: as Figure 1 to Figure 3 As shown, the coal mill used includes a coal drop pipe 2 and a grinding body 1, the grinding body 1 is provided with a coal drop opening 6, a coal outlet 8 and an air inlet 4, and the grinding body 1 includes a coal drop opening 6 and an inlet Air duct 4, add a pre-drying device at the coal drop port 6 at the front end of the grinding body 1 to pre-dry the coal entering the grinding body (1), so that the drying output and working conditions of the grinding body 1 can be improved, thereby improving the coal grinding efficiency. machine output, reduce the unit consumption of the coal mill, and reduce the wear of the grinding roller. The pre-drying device includes a circular cylindrical body 7, which is composed of an upper end cover 71, an outer sleeve 72 and an inner sleeve 73. The outer sleeve The air inlet pipe 3 is arranged on the pipe 72, and the air inlet pipe 3 is divided into 2 to 4 sub-pipes before being docked with the oute...

Embodiment 2

[0025] Example 2: refer to Figure 4 , is a structural schematic diagram of the coal mill pre-drying device used in Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the diameter of the lower end of the outer sleeve 72 of the pre-drying device is the same as the diameter of the front end of the grinding body 1. The diameters of the coal drop opening 6 are the same, that is, the diameter of the coal drop opening 6 is smaller than the diameter of the inner casing 73 .

Embodiment 3

[0026] Example 3: refer to Figure 5 , is a schematic structural view of the coal mill used in Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the air inlet pipe 3 directly introduces hot air through the fan 12, and the hot air used for pre-drying can be It is produced by a general heat source, or it can be high-temperature flue gas; the access point can be the primary air at the entrance of the coal mill, the primary hot air duct, or the furnace or boiler flue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com