Foaming equipment for preparing foamed ceramic slurry

A technology of foaming equipment and foamed ceramics, which is applied in the field of foaming equipment for preparing foamed ceramic slurry, and can solve the problems of incomplete application of high-hardness ceramics, ultrafine ceramic microbead foamed slurry, etc., to achieve good wear resistance, solve Abrasion, effect of large particle size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

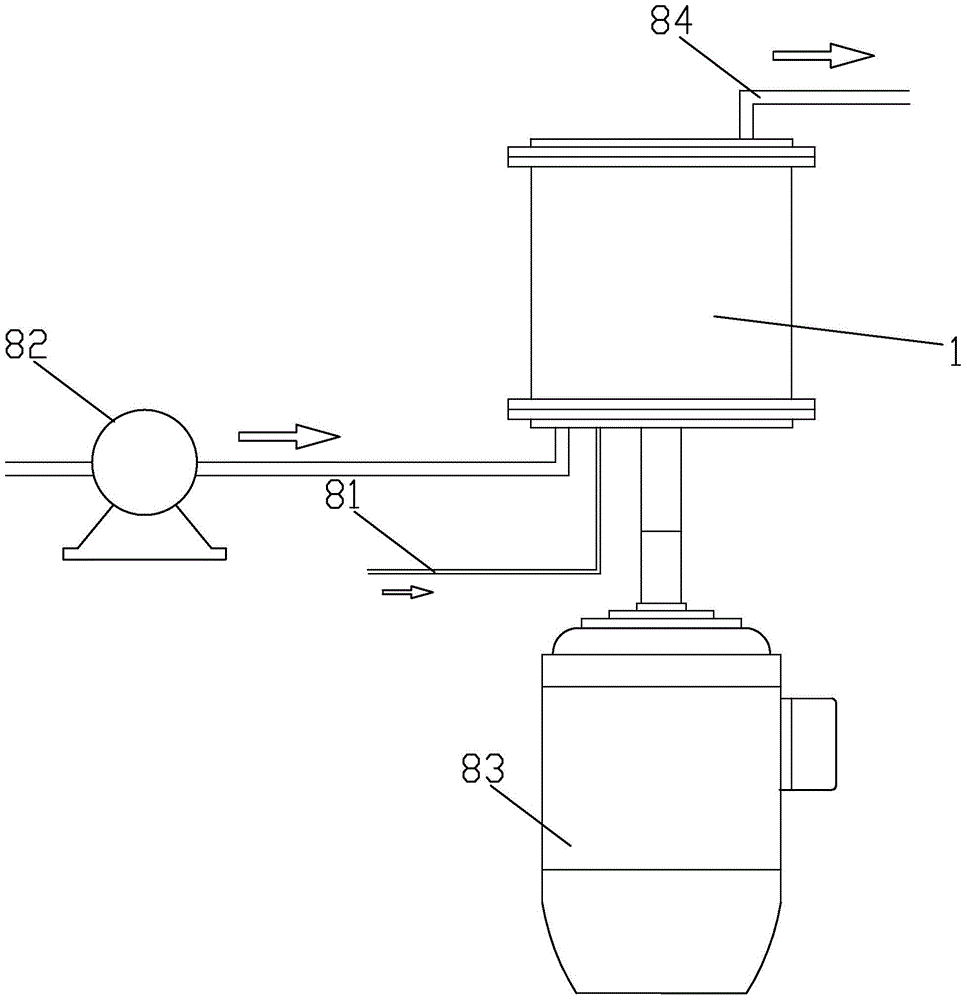

[0022] Such as Figure 1-5 As shown, the present invention includes a foaming machine 1, and its focus is that the foaming machine 1 is composed of a fixed part and a rotating part; wherein, the fixed part includes a base 11, an outer shell 12, an upper cover 13 and an outer stirring tooth group; The rotating part includes a shaft 2 and an inner stirring tooth set; the outer stirring tooth set is composed of an outer stirring tooth piece 3 and an outer spacer ring 4, and the inner stirring tooth set is composed of an inner stirring tooth piece 5 and an inner spacer ring 6; wherein, the outer shell The body 12 is arranged between the base 11 and the upper cover 13 to form a foam machine housing 10, and the outer stirring teeth 3 and the outer spacer ring 4 are fixed on the inner side of the outer casing 12; in this embodiment, the outer stirring teeth 3 are A notch 31 is provided along the notch, which can be fastened and fixed with the raised groove (not shown in the figure) p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com