Singles Flip Flatbread Maker

A flipping mechanism and flatbread technology, which is applied in dough embossing machines, food science, baking, etc., can solve the problems that the cakes are not square and beautiful, easy to form a vacuum, hard and so on, and achieve round and beautiful appearance, bright yellow and uniform color, Strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

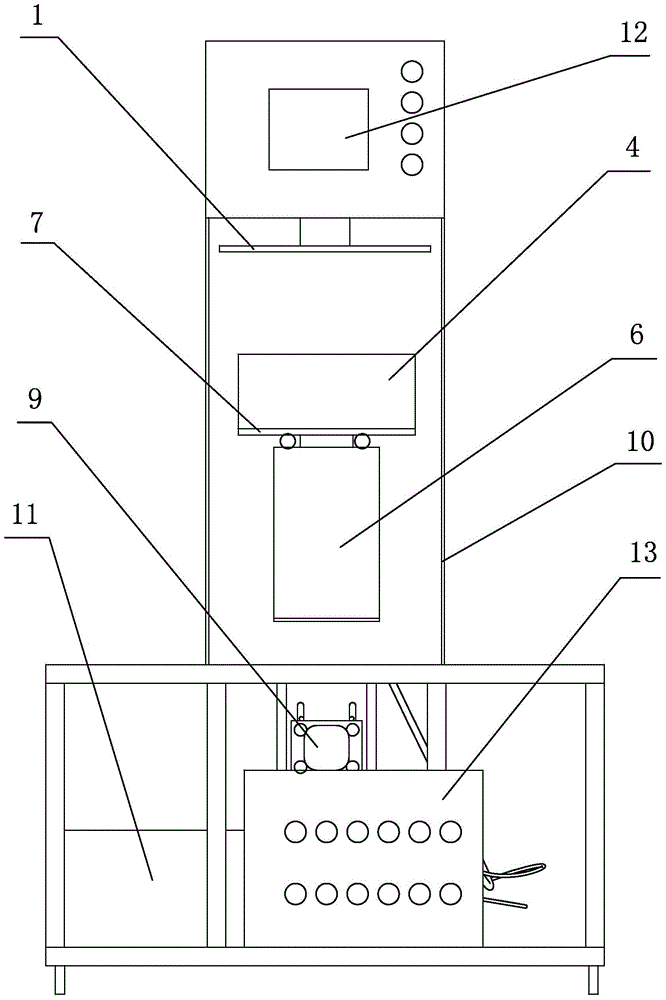

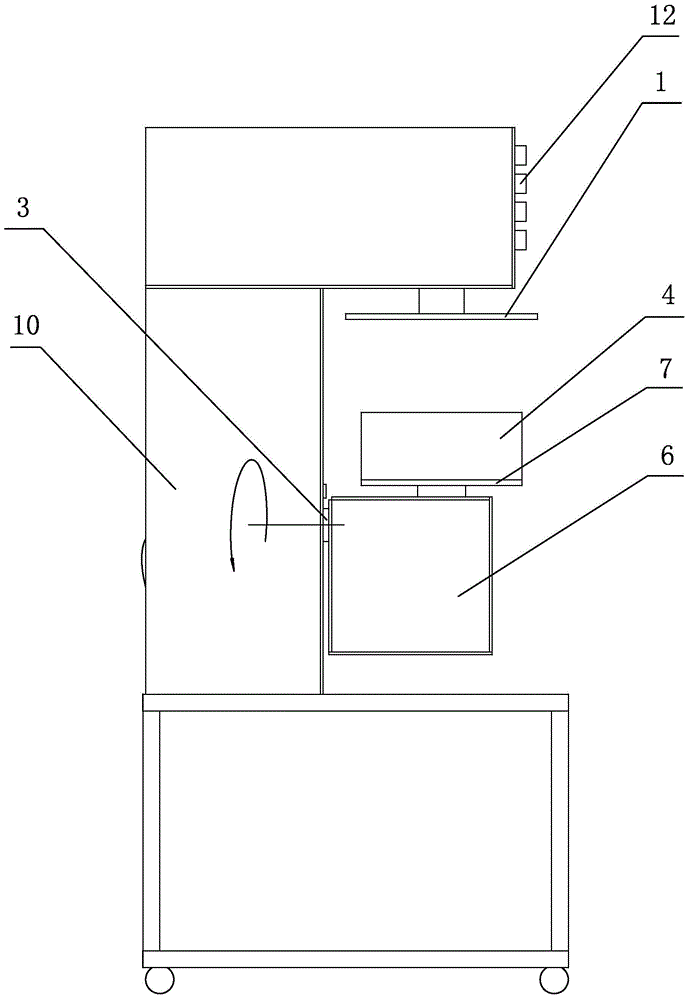

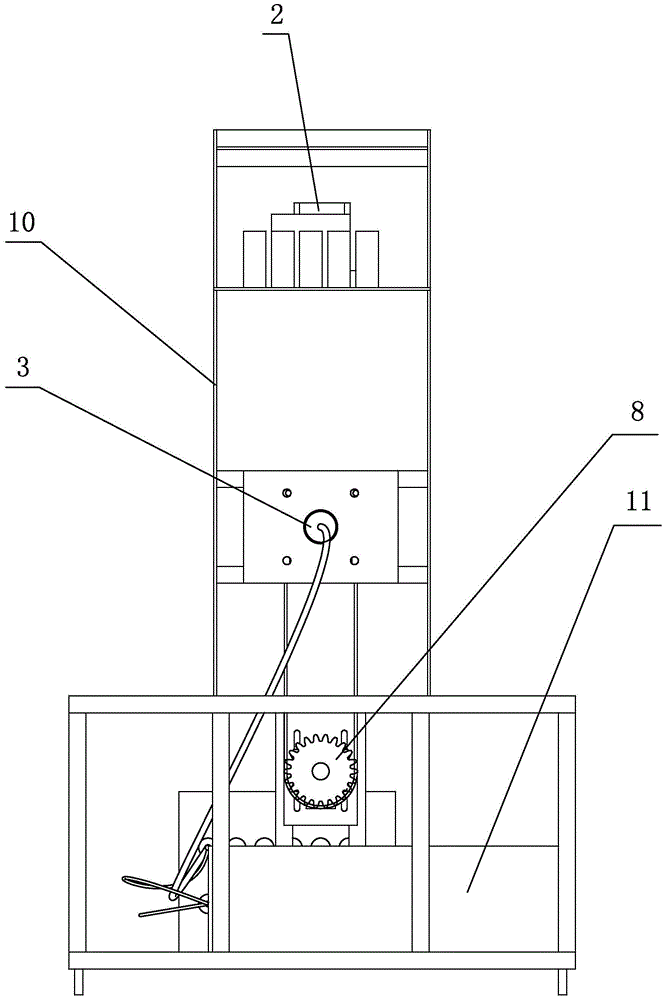

[0024] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0025] The singles overturning flatbread machine of the present invention comprises a mold, a cylinder and an overturning mechanism based on the frame 10 .

[0026] The frame 10 is composed of an upper frame, a middle frame and a lower frame, and rollers are installed on the bottom of the lower frame to realize the movement and adjustment of the machine equipment, such as figure 1 , figure 2 , image 3 shown.

[0027] The turning mechanism is arranged between the middle frame and the lower frame, and includes a turning frame 6 and a sprocket transmission pair 8 driven by a turning motor 9. Installed on the front end of the frame, the driven sprocket of the sprocket drive pair 8 is fixed coaxially with the rotating shaft 3 in the middle frame, and the turning motor 9 is installed in the lower frame below the turn f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com