Micro-capsule suspending agent containing thiamethoxam and carbosulfan and preparation method of micro-capsule suspending agent

A technology of microcapsule suspension and thiamethoxam, which is applied in the field of crop insecticide, can solve the problems of low suspension rate, achieve high suspension rate, reduce contact toxicity and odor, and slow down the hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

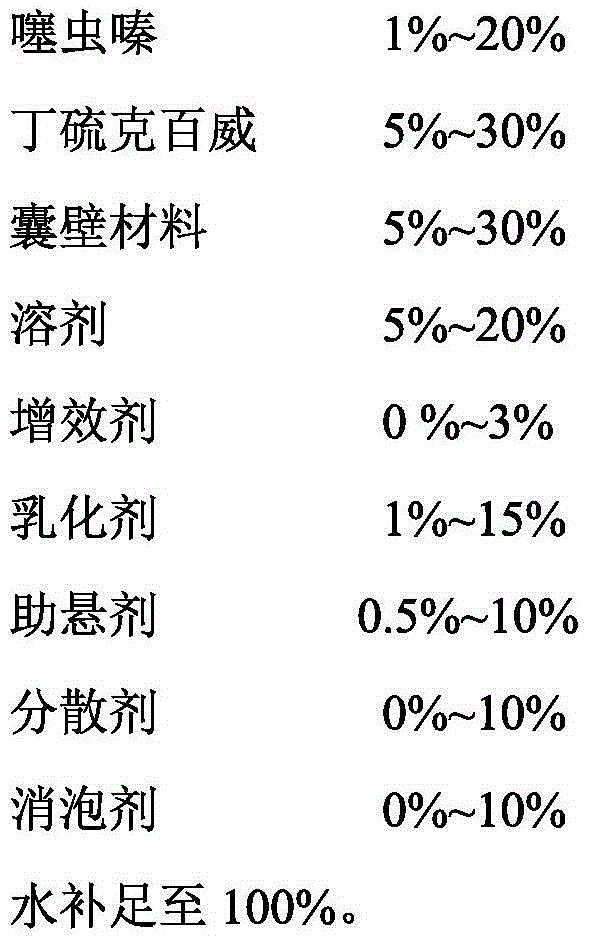

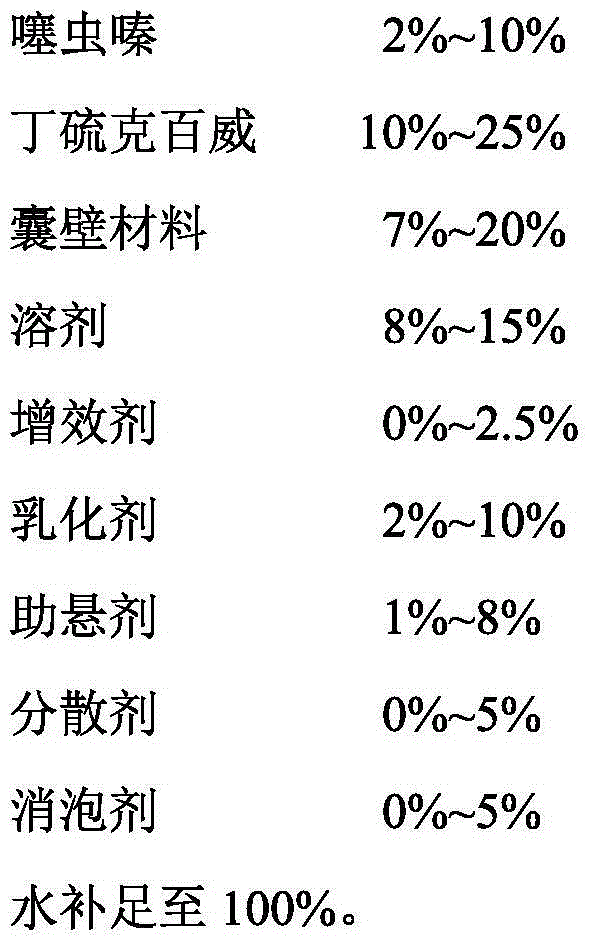

Method used

Image

Examples

Embodiment 1

[0052] Example 1. 10% Thiamethoxam Carbosulfan microcapsule suspension

[0053] Preparation:

[0054] Step 1: Preparation of oil phase: Dissolve 9% carbosulfan, 1% thiamethoxam, and 7% urea-formaldehyde resin in 5% xylene, and add 10% calcium dodecylbenzenesulfonate to prepare oil Mutually;

[0055] Step 2: Preparation of the water phase: add 5% lignosulfonate, 10% silicone defoamer, 1% xanthan gum, and 10% rhodamine B to 42% water, transfer to a stirring tank and stir to form Homogeneous;

[0056] Step 3: Preparation of emulsion: under the high-speed stirring of the mixer, the stirring speed of the mixer is greater than 2000r / min, slowly add the oil phase to the water phase to form an emulsion, until the addition is completed, use a homogenizer to cut the emulsion Form oil-in-water emulsion particles, so that the particle size D90 of the emulsion particles is less than 10 microns;

[0057] Step 4: Forming of the capsule skin material: heat the emulsion to 70°C, and stir f...

Embodiment 2

[0058] Example 2. 12% Thiamethoxam Carbosulfan microcapsule suspension (no synergist)

[0059] Preparation:

[0060] Step 1: Preparation of the oil phase: Dissolving 10% carbosulfan, 2% thiamethoxam, and 5% melamine-formaldehyde resin in 8% methanol, and adding 15% sodium polyacrylate to prepare the oil phase;

[0061] Step 2: Preparation of the water phase: Add 10% sodium methylene bis-naphthalene sulfonate, 5% polyether defoamer, and 0.5% hypromellose to 44.5% water, transfer to a stirring tank and stir to form a homogeneous phase;

[0062] Step 3: Preparation of emulsion: under the high-speed stirring of the mixer, the stirring speed of the mixer is greater than 2000r / min, slowly add the oil phase to the water phase to form an emulsion, until the addition is completed, use a homogenizer to cut the emulsion Form oil-in-water emulsion particles, so that the particle size D90 of the emulsion particles is less than 10 microns;

[0063] Step 4: Forming of the capsule skin mate...

Embodiment 3

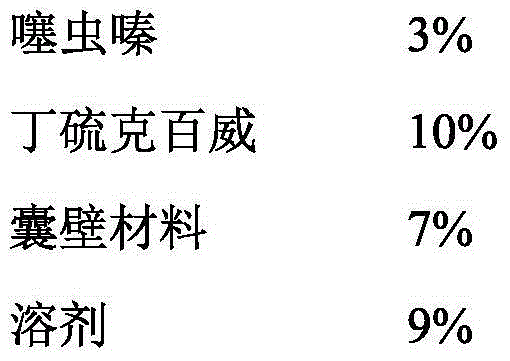

[0064] Example 3. 13% Thiamethoxam Carbosulfan microcapsule suspension

[0065] Preparation:

[0066] Step 1: Preparation of oil phase: dissolve 10% carbosulfan, 3% thiamethoxam, 3% glycerin, 4% toluene diacetonitrile in 9% benzene, and add 3% polyethylene glycol mono Stearate is formulated into an oil phase;

[0067] Step 2: Preparation of the water phase: 3% modified naphthalene sulfonate, 3% silicone defoamer, 2% pine ester-based vegetable oil, 0.05% xanthan gum, 1% magnesium aluminum silicate, 5% salt Add rhodamine B to 53.95% water, transfer to a stirring tank and stir to form a homogeneous phase;

[0068] Step 3: Preparation of emulsion: under the high-speed stirring of the mixer, the stirring speed of the mixer is greater than 2000r / min, slowly add the oil phase to the water phase to form an emulsion, until the addition is completed, use a homogenizer to cut the emulsion Form oil-in-water emulsion particles, so that the particle size D90 of the emulsion particles is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com