Transport lock, in particular for the piston of a clutch release bearing

A locking device and release bearing technology, applied in clutches, friction clutches, fluid-driven clutches, etc., can solve problems such as release bearing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

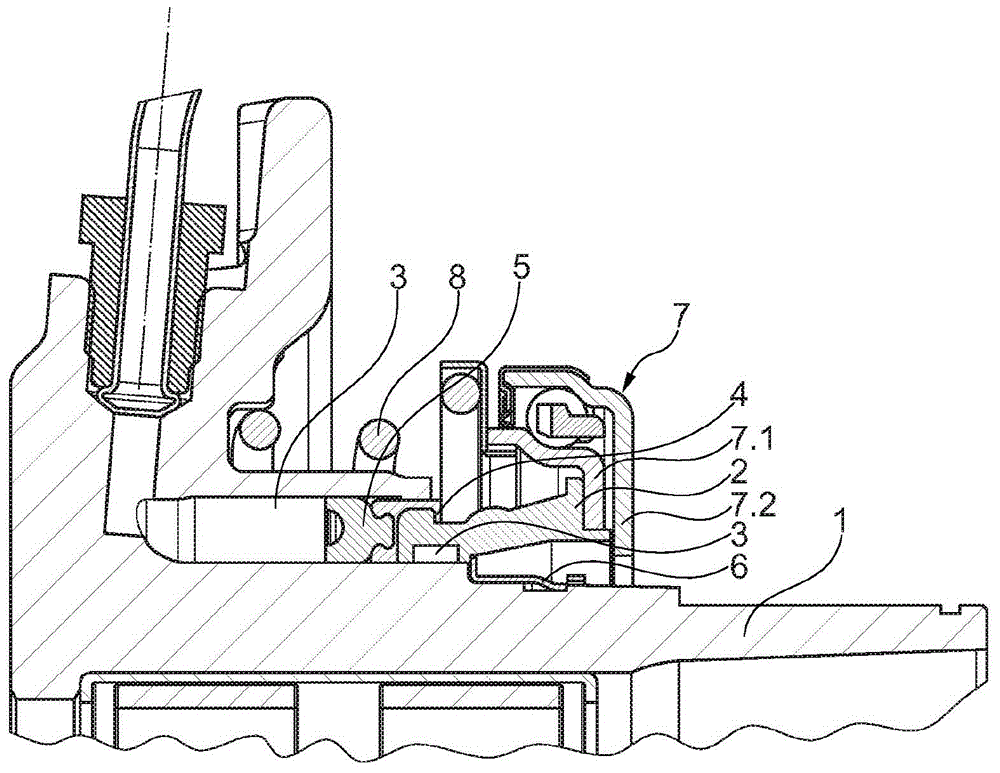

[0022] exist figure 1 shows a partial longitudinal section of a slave cylinder having a housing 1 with a circumferential housing surface 1.1 on which a piston 2 is arranged concentrically and axially movable . A seal 5 , which seals between the housing 1 and the piston 2 in the annular groove 3 of the housing 1 , is seated on one end of the piston 2 by means of the seal receptacle 4 . A release bearing 7 is connected to the other end of the piston 2 . The piston 2 is pressed onto the retaining ring 6 by means of a spring 8 which is supported on a not drawn radially outwardly directed flange of the housing 1 and via the release bearing 7 (via its inner ring 7.1) On the piston 2, said retaining ring is fixed axially firmly on the housing. The inner ring 7 . 1 of the release bearing 7 is fixed on the end of the piston 2 facing away from the seal 5 .

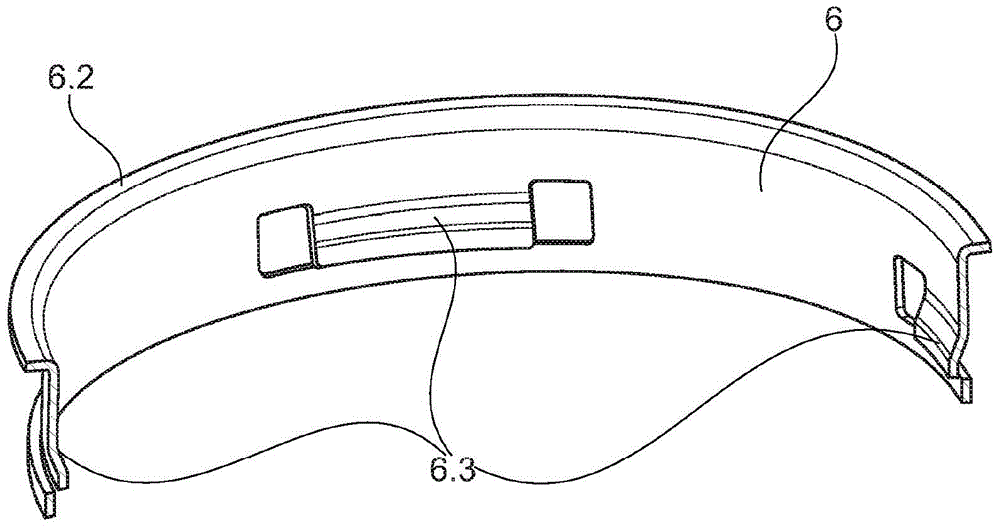

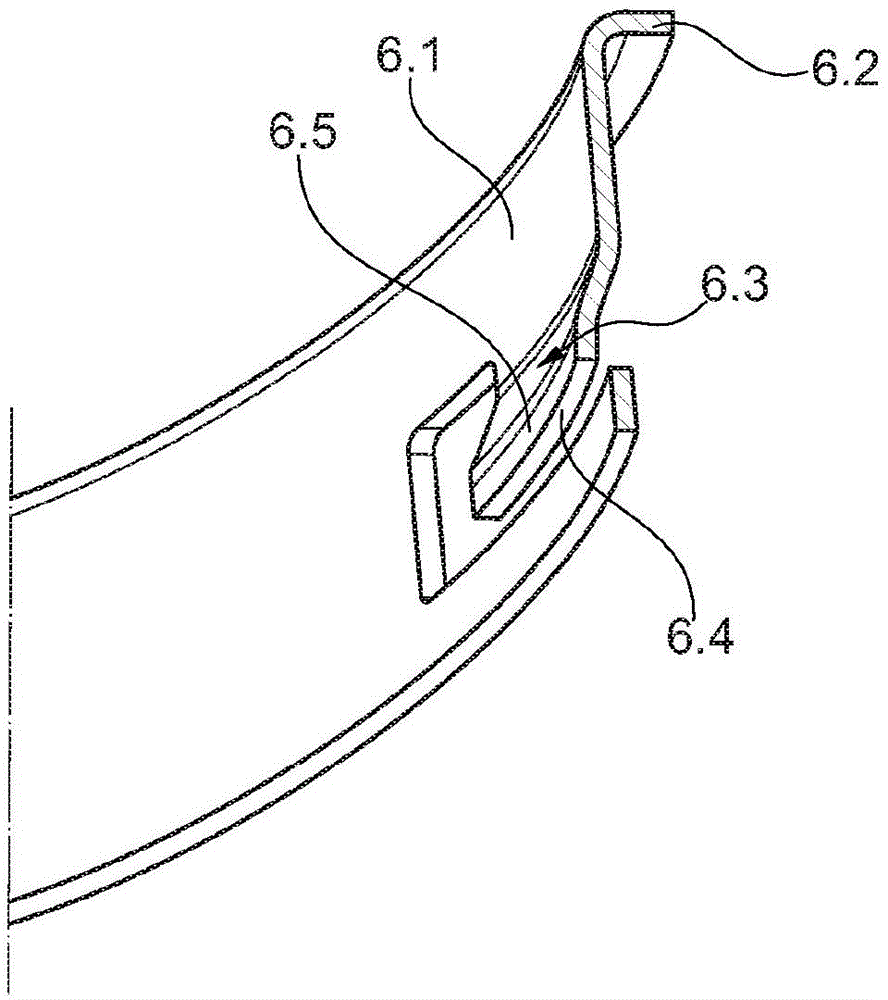

[0023] figure 2 It is shown that the retaining ring 6 has four detent hooks 6 . 3 which are arranged offset to one another a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com