Lithium-sulfur battery and preparation method thereof

A lithium-sulfur battery, lithium-sulfur technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve problems such as the inability to provide lithium sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

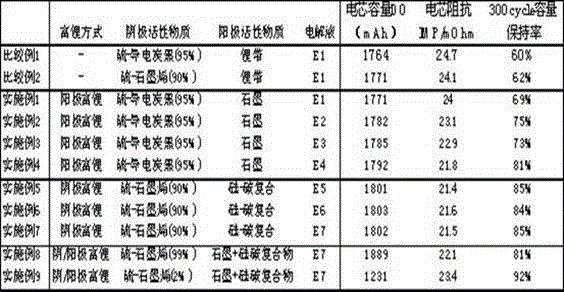

Examples

Embodiment 1

[0035] Example 1 , Preparation of cathode sheet: same as Comparative Example 1.

[0036] Preparation of anode sheet: graphite is used as the anode active material, mixed with conductive agent, adhesive and solvent to obtain a slurry, and then the anode sheet to be wound is obtained through coating, cold pressing, slitting, welding and other processes .

[0037]Preparation of lithium-rich anode sheet: choose metal lithium strip as lithium-rich material to provide lithium source, and cold-press composite the metal lithium strip and the above-mentioned anode sheet, and control the surface pressure to 1MPa, so that the metal lithium strip is tightly composited on the surface of the anode coating ( The empty current collector region does not need lithium-rich) to obtain a lithium-rich anode.

[0038] Preparation of the finished lithium-sulfur cell: wind the above-mentioned cathode sheet, separator, and lithium-rich anode sheet to obtain a bare cell, then select aluminum-plastic ...

Embodiment 2

[0040] Example 2 , different from Embodiment 1, this embodiment includes the following steps:

[0041] Electrolyte solution configuration: weigh and prepare the liquid according to the mass ratio relationship of 1,3-dioxolane: ethylene glycol dimethyl ether: vinylene carbonate = 50:50:1, and then add bis(trifluoromethylsulfonate Lithium imide was stirred, and the electrolyte E2 with lithium bis(trifluoromethylsulfonyl)imide concentration of 1mol / L was prepared for subsequent use.

[0042] Others are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0043] Example 3 , different from Embodiment 1, this embodiment includes the following steps:

[0044] Electrolyte solution configuration: Weigh and prepare the liquid according to the mass ratio relationship of 1,3-dioxolane: ethylene glycol dimethyl ether: fluoroethylene carbonate = 50:50:5, and then add bis(trifluoromethyl Lithium sulfonyl)imide was stirred, and the electrolyte E3 with a lithium bis(trifluoromethylsulfonyl)imide concentration of 1 mol / L was prepared for future use.

[0045] Others are the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com