Sintering heat tube and semiconductor refrigeration refrigerator with same

A technology of sintering heat pipes and semiconductors, which is applied in the direction of refrigerators, refrigeration components, household refrigerators, etc., can solve the problem of sintering heat pipes not achieving the effect, and achieve the effect of improving heat dissipation or cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

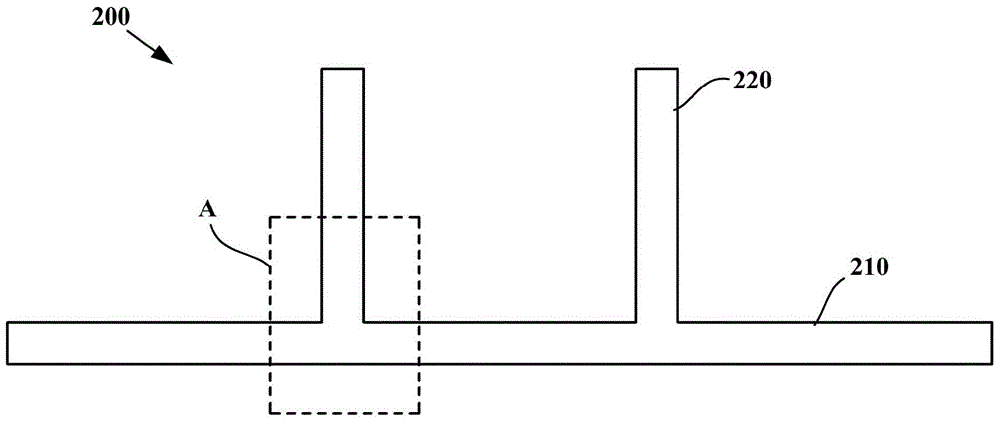

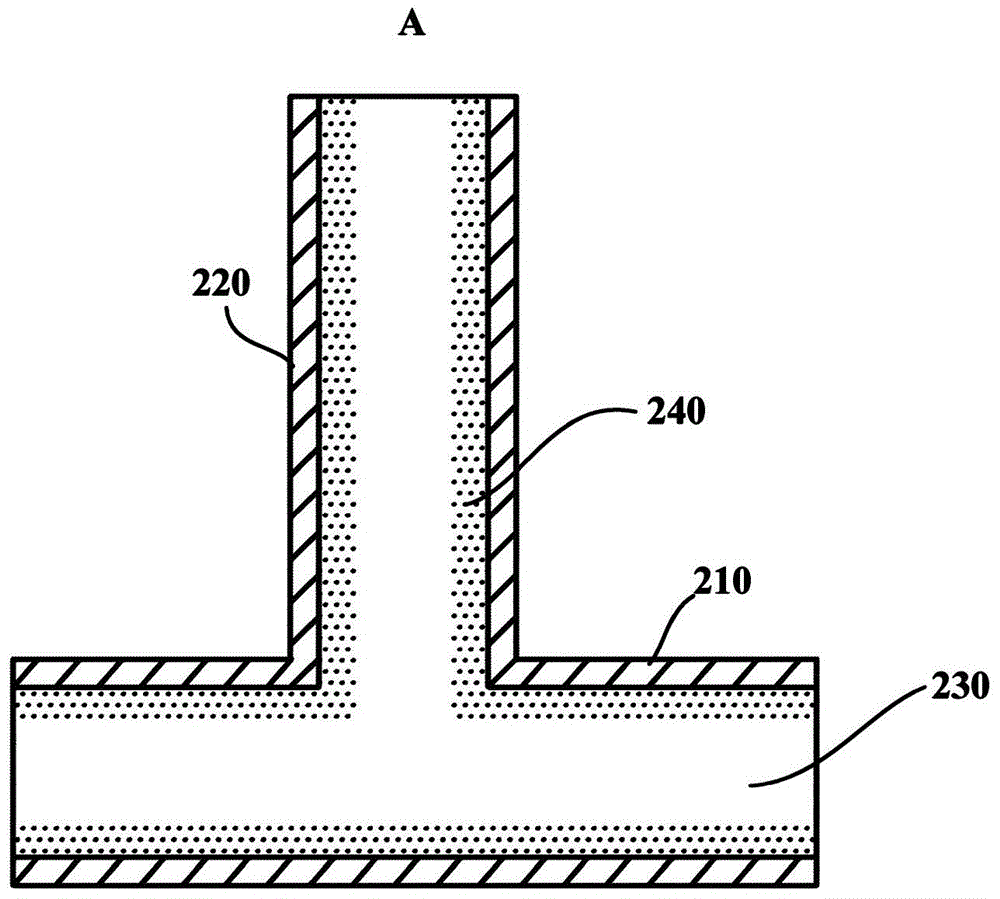

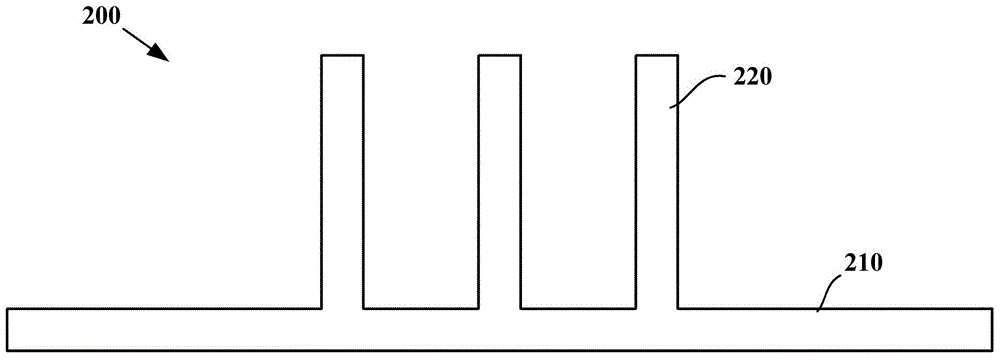

[0028] figure 1 is a schematic structural diagram of a sintered heat pipe according to an embodiment of the present invention. Such as figure 1 shown, and refer to figure 2 , the embodiment of the present invention provides a sintered heat pipe 200 with a novel structure, which has high heat dissipation or cooling efficiency, can be applied to various heat exchange devices, and is especially suitable for heat sources with high heat flux such as semiconductor refrigeration chips 150 To dissipate heat. Specifically, the sintered heat pipe 200 may include a main pipe section 210 with both ends closed. In particular, a bifurcated pipe section 220 extends from one or more positions on one side of the main pipe section 210 to improve the heat dissipation or cooling efficiency of the sintered heat pipe 200 . The working chamber 230 of each bifurcated pipe section 220 can communicate with the working chamber 230 of the main pipe section 210 to facilitate the flow of steam in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com