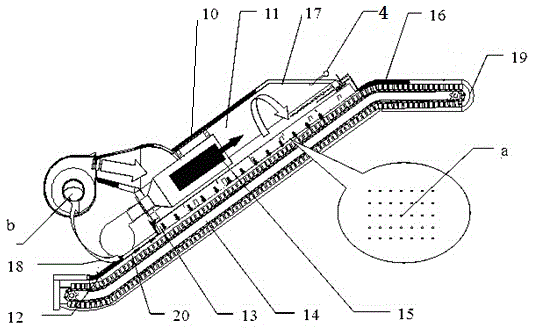

Scale plate conveyer of local thermal regeneration remixer

A compound mixer and conveyor technology, which is applied in the field of construction machinery, can solve the problems of large cooling range, unsatisfactory heating effect and difficult heating of asphalt mixture, and achieve the effect of satisfying subsequent treatment, avoiding heat loss and good heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further clearly and completely described in conjunction with the accompanying drawings in the embodiments of the present invention, and the described embodiments are only some of the embodiments of the present invention, not all of them.

[0032] The utility model relates to an in-situ heat regeneration remixer scale plate conveyor, which includes a milling drum 1, a frame body 2, a material conveying mechanism 14 and a circulation heating mechanism. Among them, the milling drum 1 is used for milling the asphalt pavement in the middle part, gathering and collecting the milled asphalt mixture, and throwing the mixture at the same time; The material outlet; the conveying mechanism 14 is arranged in the frame body 2, and is a scale plate chain transmission mechanism, which is used to receive and transport the thrown mixture; the circulation heating mechanism has a housing 17, a burner 7, a combustion chamber 15, a heating The cover 13 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com