A continuous compensation electrospinning feeding device

A feeding equipment and electrospinning technology, which is applied in the preparation of spinning solution, filament forming treatment, textiles and papermaking, etc., can solve the problems of continuous spinning, changes in the shape of spinning products, and difficult industrialization of electrospinning. Achieve the effects of compensatory adjustment of solution concentration, reliable operation and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

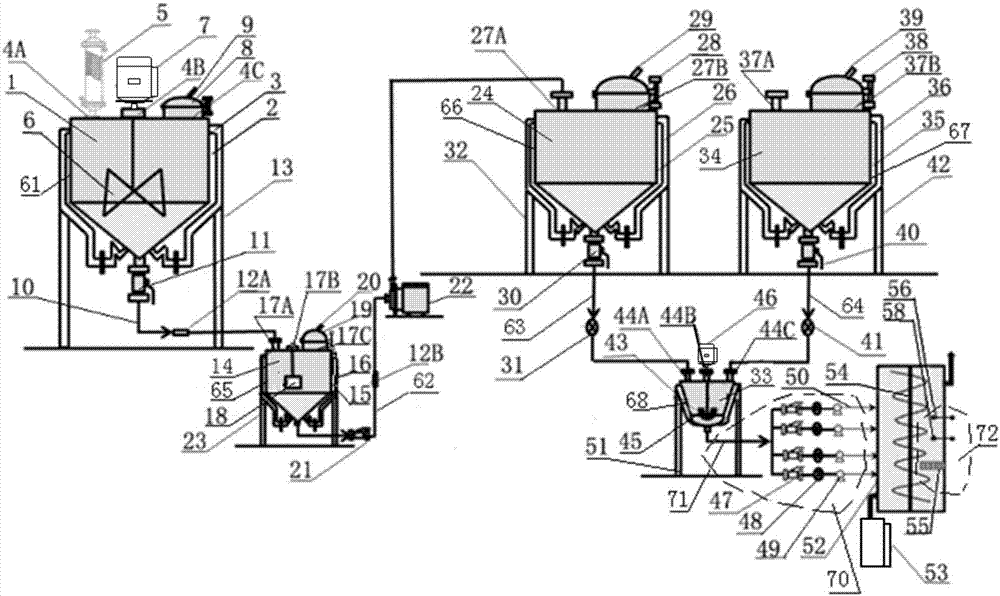

[0069] A continuous compensation type electrospinning feeding device, the feeding device comprising:

[0070] The sample stirring device 1 is used to stir the spinning sample into a uniform fluid to obtain a spinning solution;

[0071] The solution buffer device 14 is used to defoam the spinning solution to maintain the stability of the spinning solution;

[0072] Solution storage device 24, used for storing the spinning solution after defoaming;

[0073] Solvent storage device 34, used for storing solvent;

[0074] The mixing device 33 is used to mix the defoamed spinning solution and the solvent evenly, adjust and maintain the stability of the spinning solution concentration;

[0075] spinning solution tank 52 for spinning; and

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com