Method of making liquor by virtue of solid fermentation with bamboos as fluff

A solid-state fermentation and fluffy technology, which is applied in the field of brewing technology, can solve the problems of large influence on wine body, easy mildew, and musty smell affecting wine body, etc., and achieve great economic and social benefits, and are conducive to fermentation and distillation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

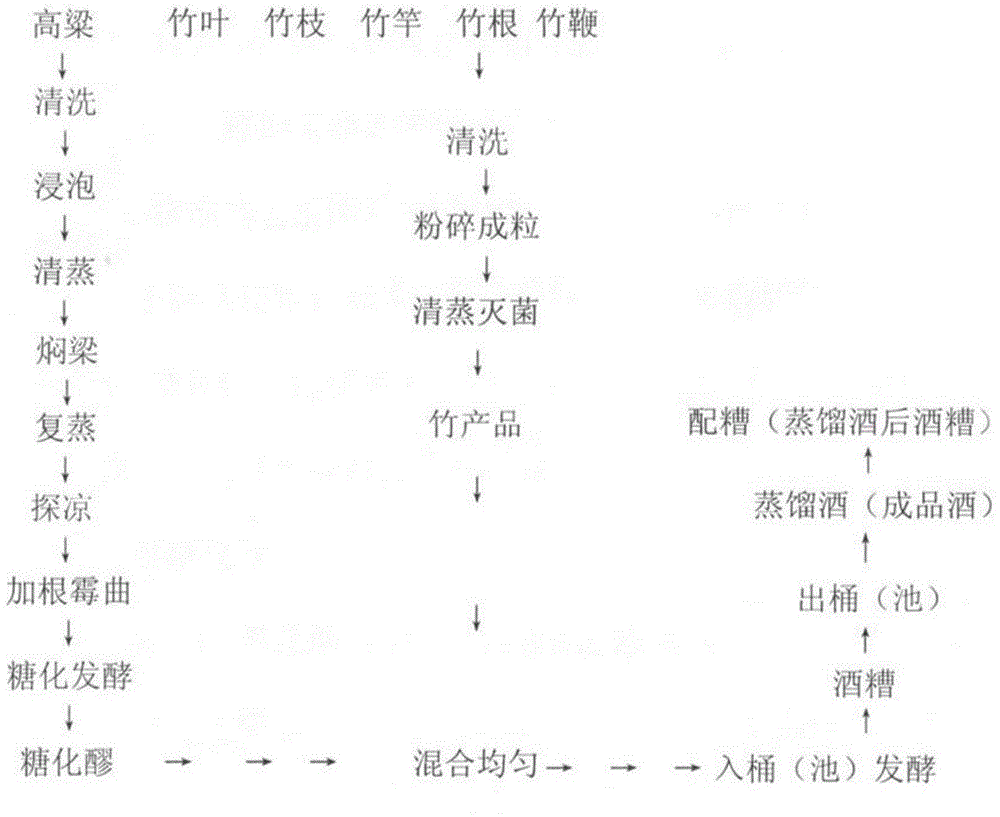

[0049] Embodiment 1 prepares bamboo fragrance type bamboo wine

[0050] Washing the bamboo whips, bamboo stems and bamboo branches according to the weight ratio of 4:3:3 as an alternative material, then crushing the bamboo whips and bamboo stems into a particle size of 8-10 mm, and crushing the bamboo branches into a particle size of 5-8 cm, Then steam together for 25 minutes, and set aside to cool.

[0051] Preparation of rhizopus koji: mix the bran and water evenly according to the mass ratio of 1:0.8, and then steam the material under normal pressure for 2 hours, then cool down to 35°C, inoculate the pure rhizopus strain with a mass fraction of 0.4%, mix well and inoculate at 35°C Under stack culture for 36h, obtain Rhizopus koji.

[0052] Take sorghum, steamed bamboo product granules and mixed grains according to the mass ratio of 30:10:60, soak the sorghum for 3 hours, remove the water and steam for 30 minutes, add an appropriate amount of warm water at about 85°C for 8 ...

Embodiment 2

[0057] Embodiment 2 prepares Xifengzhu Qingxiang type bamboo wine

[0058] Wash the Xifeng bamboo bamboo whip, bamboo pole, bamboo branch and bamboo leaf according to the weight ratio of 5:2:2:1, then crush the bamboo whip and bamboo pole into a particle size of 8-10mm, and crush the bamboo branch into granules The diameter is 5-8 cm, and the bamboo leaves are crushed into a particle size of 3-5 mm, then steamed together for 30 minutes, and cooled for later use.

[0059] Preparation of Rhizopus koji: Mix the bran and water evenly according to the mass ratio of 1:0.9, and then steam the material under normal pressure for 2 hours, then cool down to 38°C, inoculate the pure Rhizopus strain with a mass fraction of 0.4%, mix well and inoculate at 30°C Under stack culture for 36h, obtain Rhizopus koji.

[0060] Take sorghum, steamed bamboo product granules and mixed grains according to the mass ratio of 35:10:55, soak the sorghum for 4 hours, remove the water and steam for 30 minut...

Embodiment 3

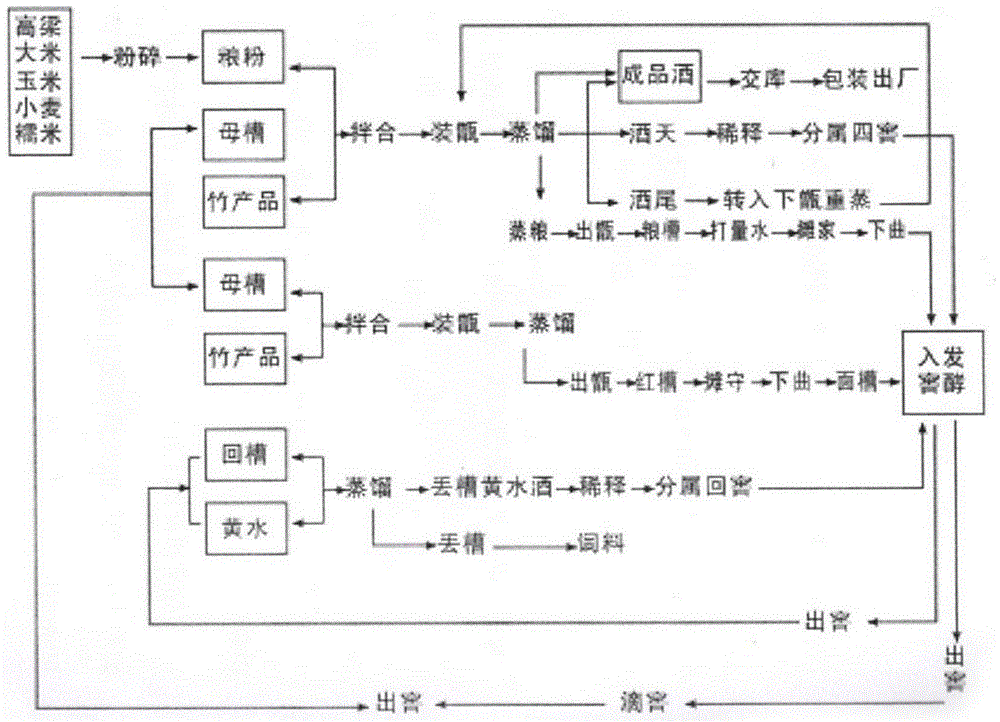

[0065] Embodiment 3 prepares Xifengzhu Luzhou-flavored bamboo wine

[0066] Wash the Xifeng bamboo bamboo whip, bamboo stem and bamboo branch according to the weight ratio of 5:3:2, then crush the bamboo whip and bamboo stem into a particle size of 8-10 mm, and crush the bamboo branch into a particle size of 5-8 cm , then steam together for 15 minutes, and set aside to cool.

[0067] Crush wheat, peas and glutinous rice with a mass ratio of 90:5:5 until 75% of the mass fraction can pass through a 20-mesh sieve, add water with a mass fraction of 30%, fully mix it, put it into a box and step on the koji, and prepare it into a 33cm×20cm×5cm Then stack the bent pieces in the culture room, the distance between the bent pieces is 4cm, and the stacking density is 30 pieces / m 3 Fill the gap between the koji and the four walls of the culture room with many years of old straw, cover the koji with a straw mat, and cover the straw mat with 25cm thick straw, and then sprinkle an appropria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com