Copper-doped Ge‑Ga‑S chalcogenide glass and method for preparing same

A chalcogenide glass, ge-ga-s technology, applied in the field of chalcogenide glass, can solve the problems of low refractive index, complex preparation of chalcogenide glass, high precision optical path adjustment, etc., and achieve good third-order nonlinear performance , the effect of good near-infrared transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the copper-doped Ge-Ga-S chalcogenide glass of each embodiment comprises the following steps:

[0020] 1) Ingredients and vacuuming: Prepare various raw materials according to the ratio and mix them evenly, then put the mixed raw materials into the quartz tube and vacuumize to 10 -5 Pa, then the raw material is packaged in a closed quartz tube;

[0021] 2) High-temperature melting and quenching: put the quartz tube packaged with raw materials into a heating furnace for high-temperature melting, the heating temperature is 950 ° C, and the heating time is 25 hours. After the heating is completed, a melt is obtained in the quartz tube, and then the quartz tube is immersed in Quench the encapsulated melt in distilled water at 10°C, take it out immediately after the wall is removed, and obtain a semi-finished product of copper-doped Ge-Ga-S chalcogenide glass in the quartz tube;

[0022] 3) Annealing and cooling: anneal the semi-finished copper-dop...

Embodiment 2

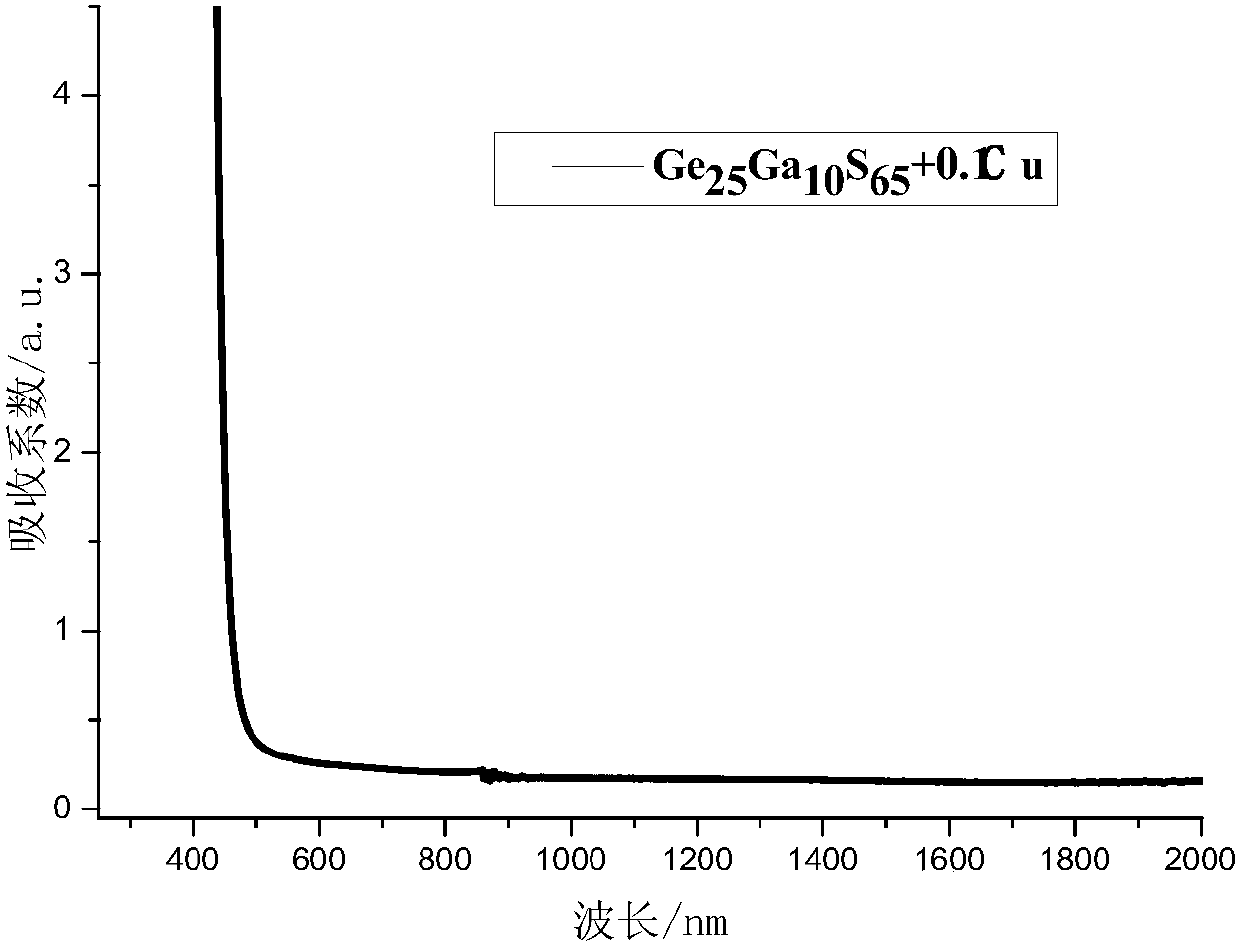

[0024] The absorption spectrum of the copper-doped Ge-Ga-S chalcogenide glass of embodiment 2 is shown in figure 1 . From figure 1 It can be seen that in the near-infrared band, its absorption is very small, and it has good near-infrared transmission characteristics.

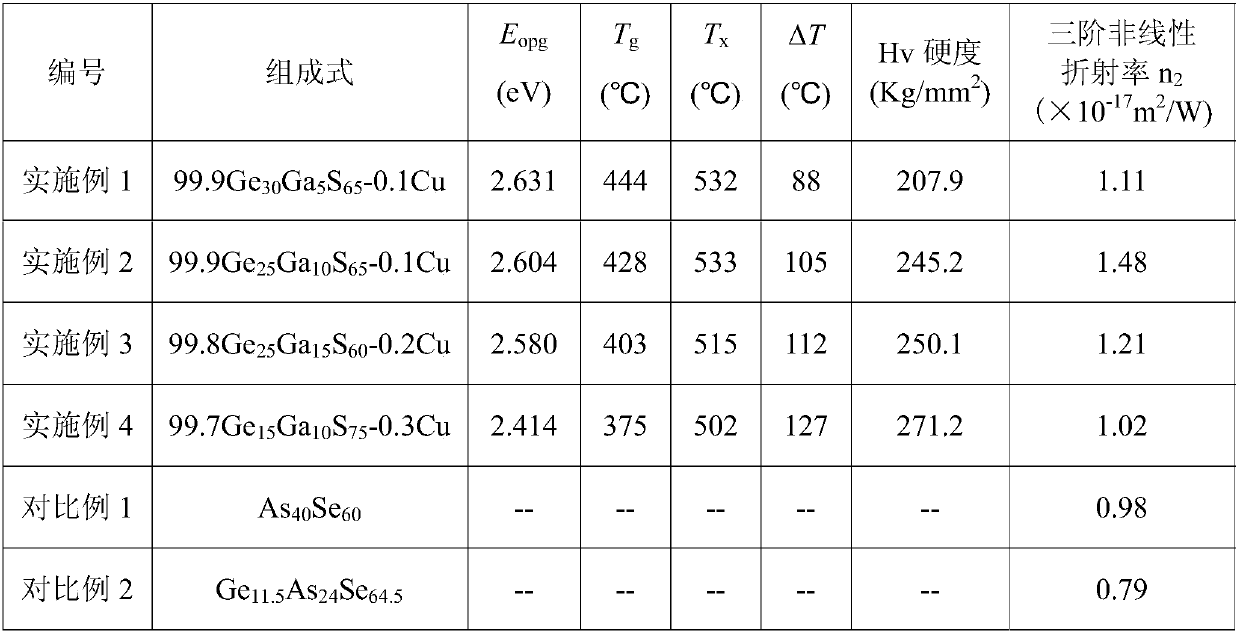

[0025] Table 1 Raw material ratio and properties of glass in Examples 1-4 and Comparative Examples 1-2

[0026]

[0027] It can be seen from Table 1 that the copper-doped Ge-Ga-S chalcogenide glass of the present invention, as the Cu content increases, the ΔT of the glass sample increases gradually, indicating that the introduction of Cu ions can improve the anti-devitrification ability of the sample , it can be seen from the measured hardness data that the hardness of the sample also increases with the increase of Cu content. The third-order nonlinear refractive index of the copper-doped Ge-Ga-S chalcogenide glass of the present invention is higher than that of the As-containing chalcogenide glass, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com