Porous NiO/CeO2 hybrid nanosheet array, and preparation method and application thereof

A nano-sheet array and nano-sheet technology are applied in the field of porous NiO/CeO2 hybrid nano-sheet arrays and their preparation to achieve the effect of being beneficial to large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

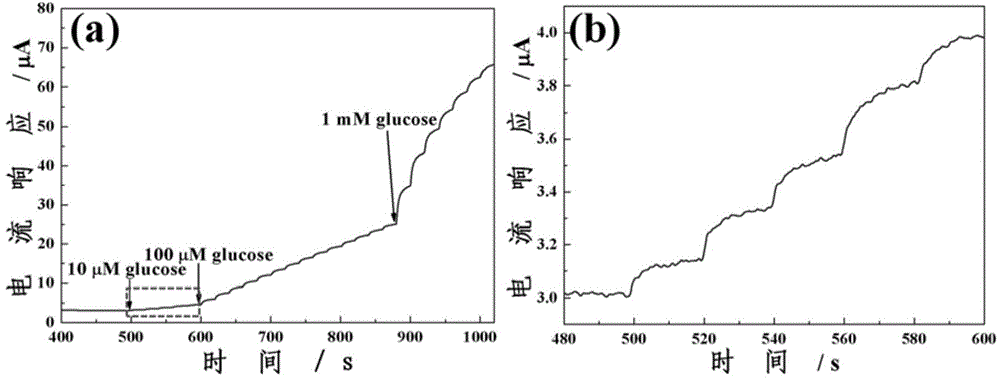

Image

Examples

Embodiment 1

[0021] 1. NiO / CeO 2 Preparation of Nanosheet Array Precursor

[0022] (1) Put nickel foam (2cm*3cm) purchased from the market into 3 mol / L hydrochloric acid and ultrasonically clean it for 30 minutes to remove the oxide layer on the surface, and then use deionized water and absolute ethanol to clean it alternately;

[0023] (2) Dissolve 0.152g of cerium nitrate, 0.026g of ammonium fluoride and 0.1051g of urea in 35 mL of distilled water to form a mixed solution and transfer it to an autoclave;

[0024] (3) Put the nickel foam obtained in step 1 into an autoclave containing the mixed solution obtained in step 2, seal it and perform hydrothermal treatment in an oven at 120°C for 12 hours;

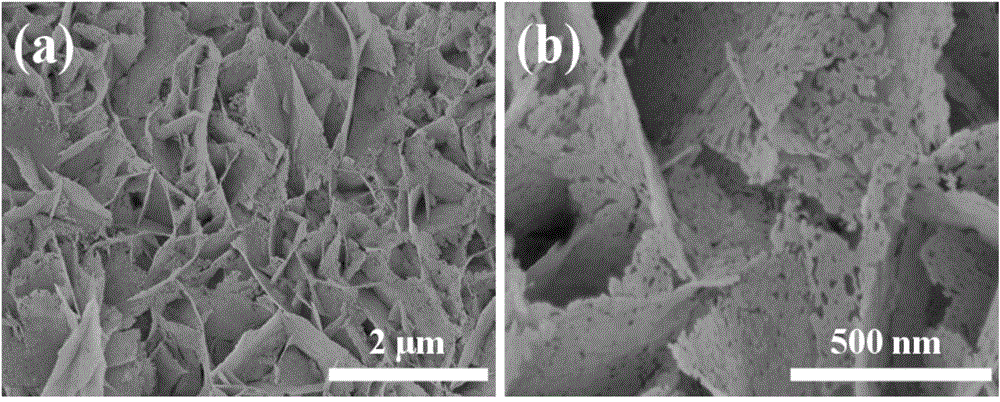

[0025] 2. Porous NiO / CeO 2 Fabrication of nanosheet arrays

[0026] The sample obtained after hydrothermal treatment is calcined in air atmosphere, the calcination temperature is 500°C, and the holding time is 2 hours, and the porous NiO / CeO can be obtained. 2 Nanosheet arrays.

[0027] ...

Embodiment 2

[0029] 1. NiO / CeO 2 Preparation of Nanosheet Array Precursor

[0030] (1) Put nickel foam (2cm*3cm) purchased from the market into 3 mol / L hydrochloric acid and ultrasonically clean it for 30 minutes to remove the oxide layer on the surface, and then use deionized water and absolute ethanol to clean it alternately;

[0031] (2) Dissolve 0.152g of cerium nitrate, 0.026g of ammonium fluoride and 0.1051g of urea in 35 mL of distilled water to form a mixed solution and transfer it to an autoclave;

[0032] (3) Place the nickel foam obtained in step (1) in an autoclave containing the mixed solution obtained in step (2), seal it and perform hydrothermal treatment in an oven at 140°C for 12 hours;

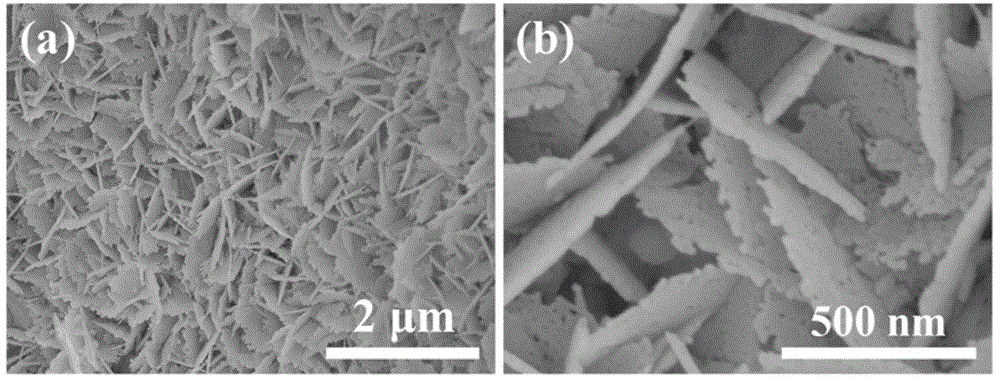

[0033] 2. Porous NiO / CeO 2 Fabrication of nanosheet arrays

[0034] The sample obtained after hydrothermal treatment is calcined in air atmosphere, the calcination temperature is 500°C, and the holding time is 2 hours, and the porous NiO / CeO can be obtained. 2 Nanosheet arrays.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com