Electric and spring coupling pressure foot and control method of automatic hole-making end effector

An end effector, spring coupling technology, applied in the direction of manufacturing tools, clamping, support, etc., can solve the problem that the pressure foot cannot stably maintain the pressure state, the pneumatic control system does not have high output stiffness, and the overall quality of the end effector is high. Achieve significant vibration absorption effect, good vibration absorption effect, and good pressure control stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings:

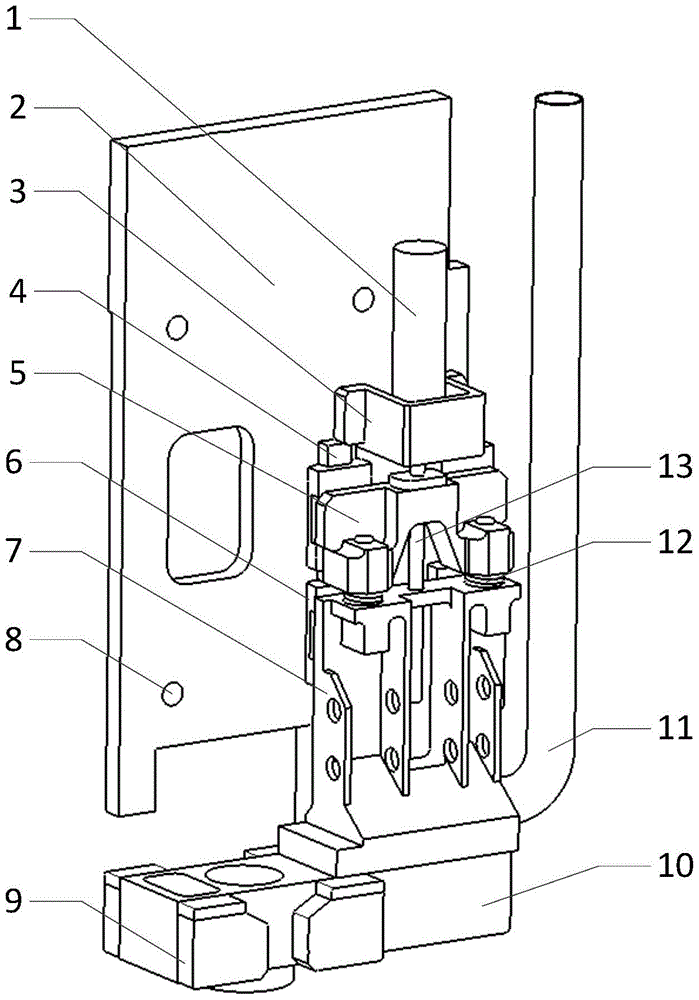

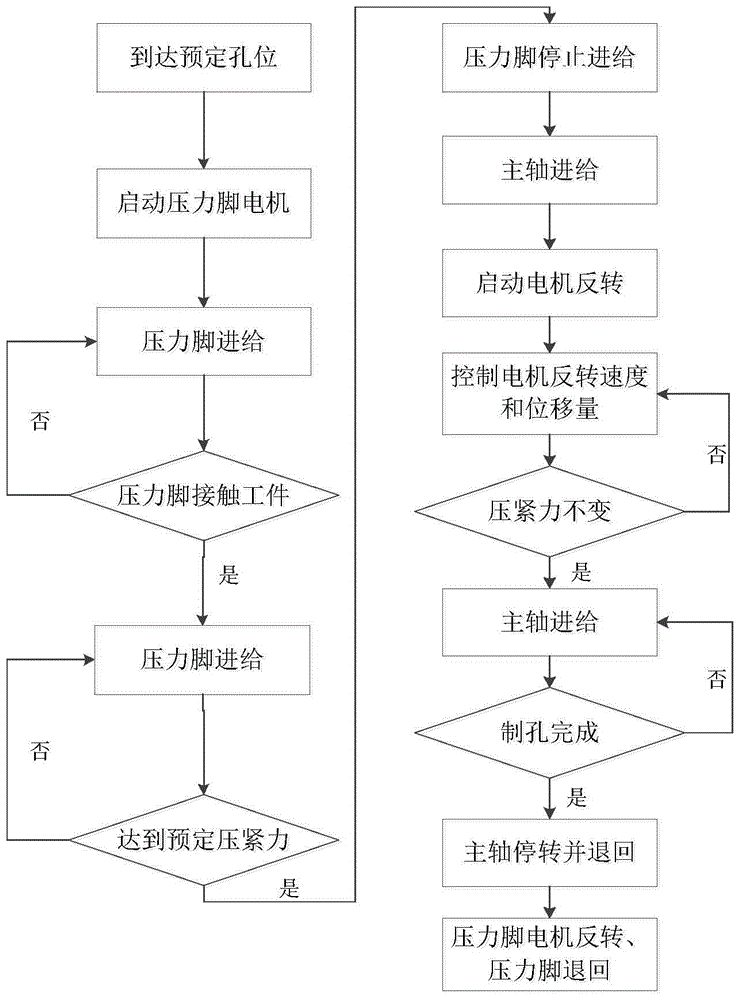

[0029] like figure 1 The motorized and spring-coupled pressure feet of the automatic hole-making end effector shown are mounted on the spindle base plate 2 on which the hole-making spindle is mounted, and the spindle base plate 2 is screwed to the inner cross of the end effector through threaded holes 8 On the sliding table, the hole-making spindle feeds with the movement of the spindle base plate 2 on the cross sliding table, and is characterized in that: the pressure foot includes a pressure script body and a pressure foot servo system, and the pressure script body is connected to the pressure foot through the pressure foot connecting seat 7 The base 10, the pressure foot connecting seat 7 is installed on the guide rail 4 on the main shaft base plate 2 through the slider 6; the pressure foot servo system includes a servo motor 1, a host computer that controls the ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com