Three-spot welding device

A three-spot welding and equipment technology, applied in welding equipment, welding equipment, resistance welding equipment, etc., can solve the problems of long welding time, difficult to guarantee welding quality, and heavy workload of welding bead cleaning, so as to reduce labor intensity and production Cost reduction, reduction of secondary processing steps, and realization of product diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

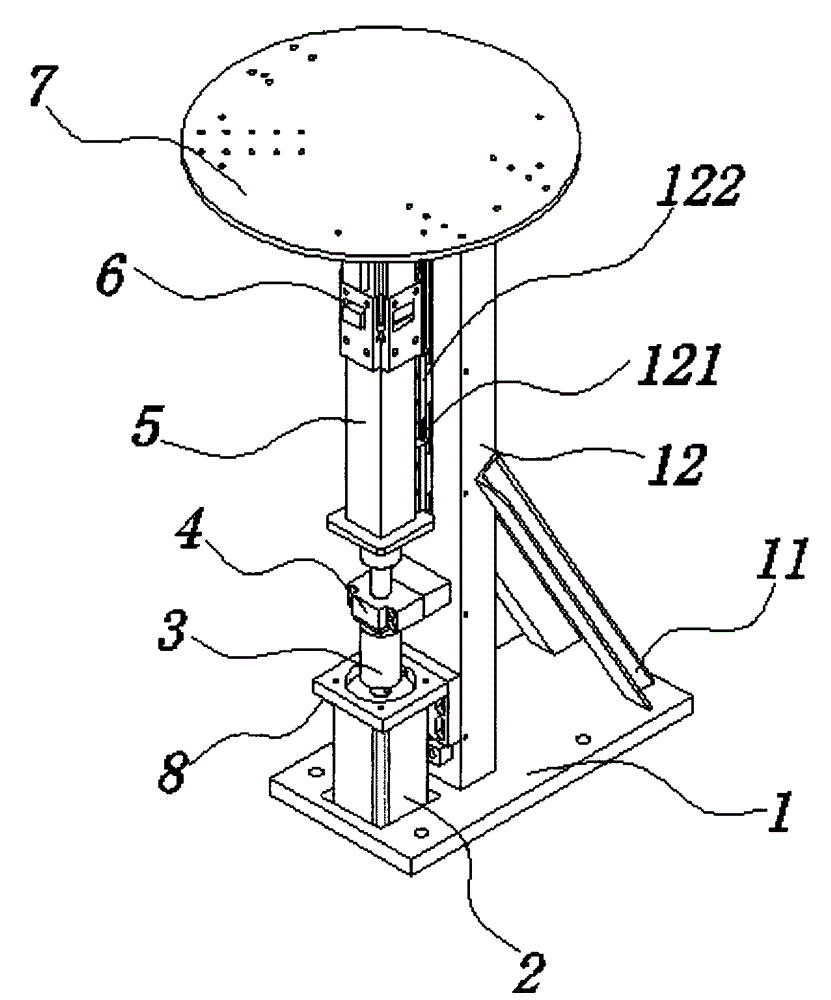

[0016] A three-spot welding equipment, including a fixed base plate 1, a lifting servo motor 2, a coupling 3, a bearing seat 4, a lifting device 5, a rotating servo motor 6, and a working turntable 7. The fixed base plate 1 is integrally formed with a square Column 12, the working turntable 7 is located on the top of the square column 12, the lifting device 5 is located on one side of the square column 12 below the working turntable 7, and the lifting device 5 is provided with Rotate the servo motor 6, the bearing seat 4 is fixed on one side of the square column 12 and is located below the lifting device 5, the fixed base plate 1 is provided with a lifting servo motor 2; the working turntable 7 The rotary servo motor 6 is connected with a flat key, the rotary servo motor 6 and the lifting device 5 are fixed with a bolt pressure plate, the lifting device 5 is connected with the bearing seat 4 using a flat key, and the lifting device 5 is connected with the lifting servo motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com