Hydrogenation catalyst, preparation and application thereof

A hydrogenation catalyst and oxide technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited surface area, decreased molecular sieve crystallinity, irregular pore structure, etc., and achieve excellent application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Mix the metering raw materials in sequence at the initial gel ratio silica:alumina:sodium oxide:template:water=60:1:5:52:1950, wherein the silicon source is silica sol and the aluminum source is sodium metaaluminate , The lye is sodium hydroxide, the template is tetraethylammonium hydroxide, fully stirred to form a gel, and then put into a polytetrafluoroethylene-lined high-pressure reactor, the crystallization temperature is set at 140 ° C, and the constant temperature crystallization 72 hours. The solid product was separated, washed with deionized water until neutral, and dried in an air atmosphere at 85° C. for 24 hours to obtain a Beta-1 molecular sieve.

Embodiment 2

[0016] Mix the metering raw materials in sequence at the initial gel ratio silica:alumina:sodium oxide:template:water=40:1:3:28:1630, wherein the silicon source is tetraethyl orthosilicate and the aluminum source is partial Sodium aluminate, lye is sodium hydroxide, template is tetraethylammonium hydroxide, fully stirred to form a gel, and then put into a polytetrafluoroethylene-lined high-pressure reactor, and the crystallization temperature is set at 132°C. Constant temperature crystallization for 120 hours. The solid product was separated, washed with deionized water until neutral, and dried in an air atmosphere at 85° C. for 24 hours to obtain a Beta-2 molecular sieve.

Embodiment 3

[0018] Take 1L of the Beta molecular sieve liquid prepared by the method in Example 1, add 19.5g of pore-forming agent cetyltrimethylammonium chloride, adjust the pH value of the solution to 6.8 after mixing evenly, slowly add the diluted pre-hydrolyzed and mixed solution of tetraethyl orthosilicate and aluminum nitrate, wherein the molar ratio of silicon source to surfactant is 1:0.26, and the molar ratio of silicon source to aluminum source is 80. The coating reaction was carried out at a temperature of 30° C. at a rotation speed of 1000 rpm for 5 hours. Put the above solution into a hydrothermal reaction kettle and age at 85°C for 45 hours. After the whole aging process, the obtained molecular sieve solids are separated, washed and dried, and finally roasted at 550°C for 3 hours in an air atmosphere to remove the molecular sieve pores. Surfactants to obtain mesoporous silica-alumina-coated Beta molecular sieves, denoted as ASABeta-1.

PUM

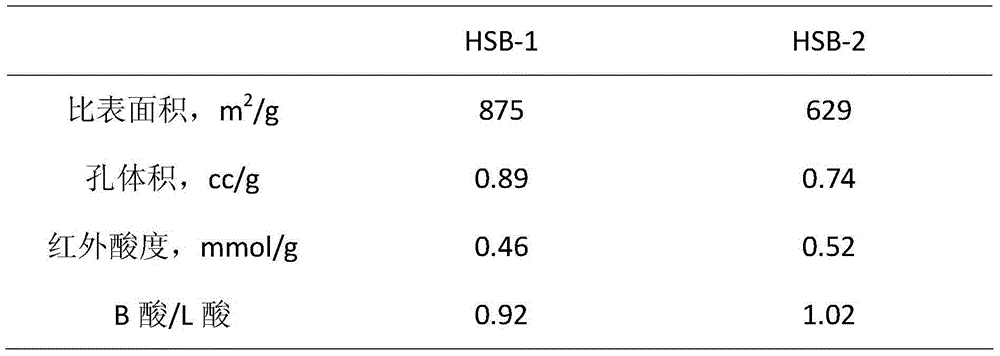

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com