Carbon dioxide capturing equipment

A technology of carbon dioxide and equipment, applied in the field of carbon dioxide gas treatment, can solve the problems of impurity and by-product blockage, fluctuation of production parameters, low temperature of desorption tower solution, etc., and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

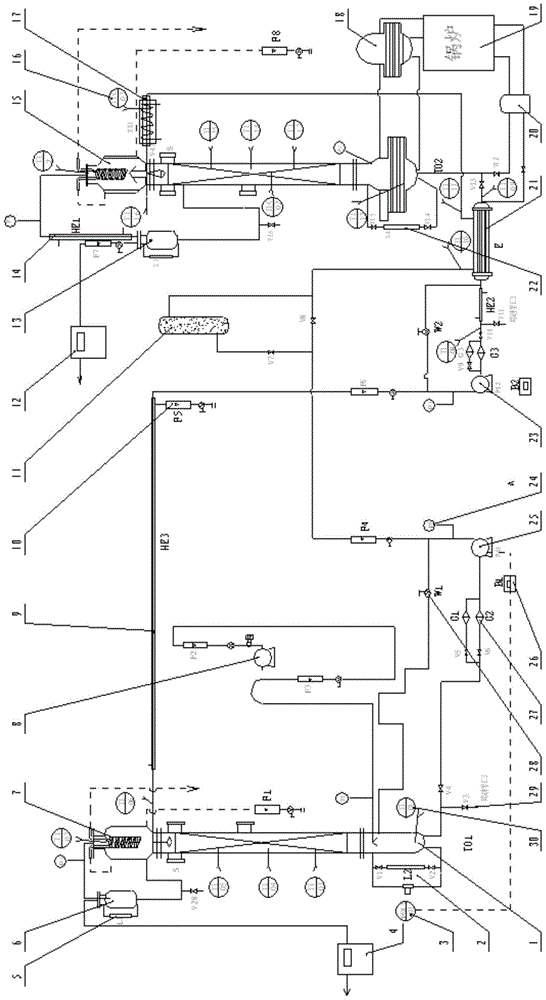

Image

Examples

Embodiment 1

[0034] A carbon dioxide capture device, the device mainly includes an absorption tower 1, a fan 8, a condenser A 9, a desorption tower 15, a heater 17, a heating element 19, a lean-rich liquid heat exchanger 21, a lean liquid pump 23, a rich liquid Liquid pump 25 and filter 27.

[0035] Among them, the absorption tower 1 is a cylindrical packed tower, and the packing is packed in two stages, and the ratio of height to diameter is 10:1. The material of the absorption tower 1 can be carbon steel; the flue gas enters from the lower half of the tower to form countercurrent absorption; the volume ratio of the gas phase and the liquid phase in the absorption tower 1 is the gas-liquid ratio, and the gas-liquid ratio is 1400-1500. The solution after the carbon dioxide absorbent absorbs carbon dioxide in the absorption tower 1 is called rich liquid.

[0036] An absorption tower 1 is equipped with a fan 8, and the wind pressure of the fan 8 can be 10000Pa.

[0037] The working tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com