Manufacturing method of battledore frame

A badminton racket and a production method technology, which are applied to rackets, string rackets, sports accessories, etc., can solve the problems of weak ball control ability and arm shock, and achieve strong ball control ability, no shock and pain in the arm, Good shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

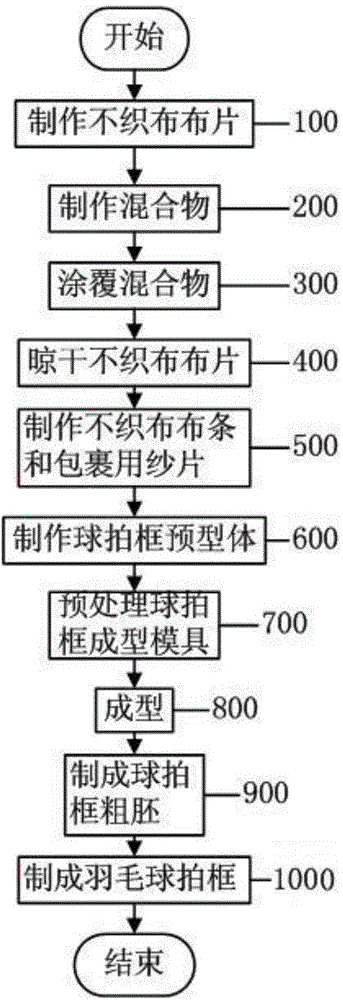

[0037] Such as figure 1 Shown embodiment is a kind of manufacturing method of badminton racket frame, comprises the steps:

[0038] Step 100, making the non-woven cloth sheet

[0039] Cut the non-woven fabric into several pieces of 125CM×70CM rectangular non-woven fabric pieces;

[0040] Step 200, making the mixture

[0041] According to the mass ratio of 1:1:0.5, the liquid epoxy resin, methyl ethyl ketone liquid and foaming powder are stirred evenly to obtain a mixture;

[0042] Step 300, coating mixture

[0043] Within 10 seconds, use the tool to apply the mixture on both sides of each non-woven sheet;

[0044] Step 400, drying the non-woven fabric piece

[0045] Dry each piece of non-woven fabric coated with the mixture naturally;

[0046] Step 500, making non-woven fabric strips and wrapping gauze sheets

[0047] Each piece of cloth is cut into 60cm by 0.7cm rectangular non-woven fabric strips with a cutting machine;

[0048] Stack and paste several pieces of glas...

Embodiment 2

[0060] Step 100, cutting the non-woven fabric into several pieces of 125CM×70CM rectangular non-woven fabric pieces;

[0061] Step 200, according to the mass ratio of 1:1:0.7, the liquid epoxy resin, butanone liquid and foaming powder are evenly stirred to obtain a mixture;

[0062] Step 300, within 10 seconds, use a tool to coat the mixture on the front and back sides of each piece of non-woven cloth;

[0063] Step 400, drying each piece of non-woven fabric coated with the mixture naturally;

[0064] Step 500, use a cutting machine to cut each piece of cloth into a rectangular non-woven cloth strip of 60cm by 0.7cm;

[0065] Stack and paste several pieces of glass fiber cloth with different fiber orientations in sequence, or stack and paste several pieces of carbon fiber cloth with different fiber orientations in sequence to obtain wrapping gauze sheets;

[0066]In step 600, the staff manually roll each rectangular strip of cloth into a strip-shaped solid body with a circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com