Brushing-off machine for sunflower seeds

A technology of sunflower seeds and dropping machines, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problem of time-consuming and labor-intensive sunflower seeds, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

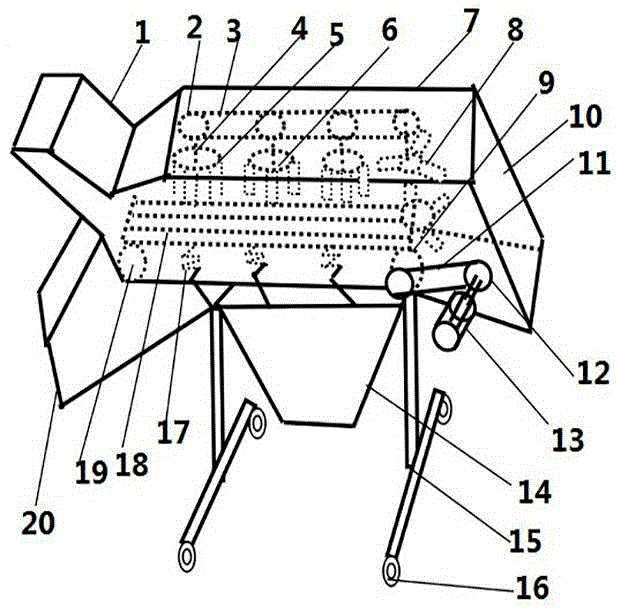

[0014] Such as figure 1 As shown, the design consists of feed inlet 1, flywheel 2, belt 3, rotating shaft 4, soft brush disc 5, glue stick disc 6, casing 7, gear 8, driving wheel 9, faceplate outlet 10, transmission wheel 11, transmission belt 12. Motor 13, melon seed outlet 14, bracket 15, wheel 16, spring 17, conveyor belt 18, driven wheel 19, tidbits outlet 20; connect motor 7 to power supply, motor 7 will drive transmission wheel 11, transmission belt 12, driving wheel 9 rotates to drive the conveyor belt 18 to rotate, the driving wheel 9 drives the gear 8 close to it to rotate, the gear 8 at the lower end drives the gear 8 at the upper end to rotate, the gear 8 drives the belt 3 to drive the flywheel 2 to rotate, and the flywheel 2 drives the soft brush disc 5 and Glue stick disc 6 rotates, and puts the sunflower disc with grain upwards in the feed port 1, and the sunflower disc slides onto the conveyor belt 18. The size of the sunflower plate will be clamped between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com