Assembly-line LED (light emitting diode) display unit uniformity detection method, system and device

A display unit and assembly line technology, applied in the direction of static indicators, instruments, etc., can solve the problems of unable to produce and supply, unable to know whether the LED light board is qualified, and unable to know the uniformity of brightness and chromaticity of the LED light board, so as to save manpower and material resources , improve efficiency and automation, and improve the effect of factory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

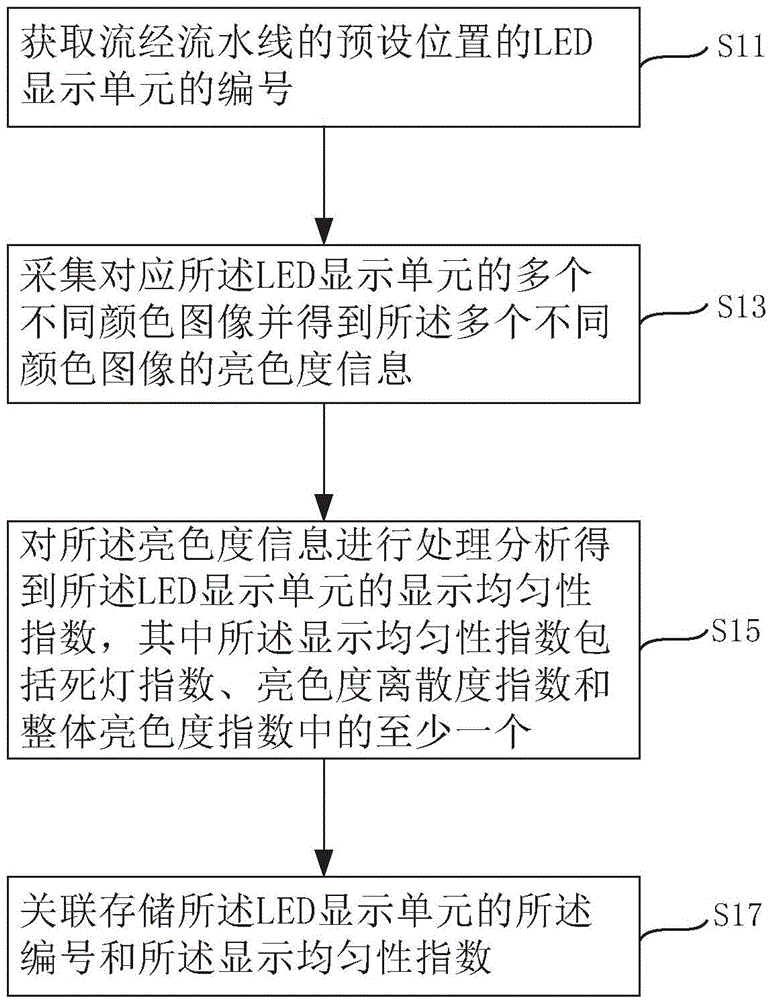

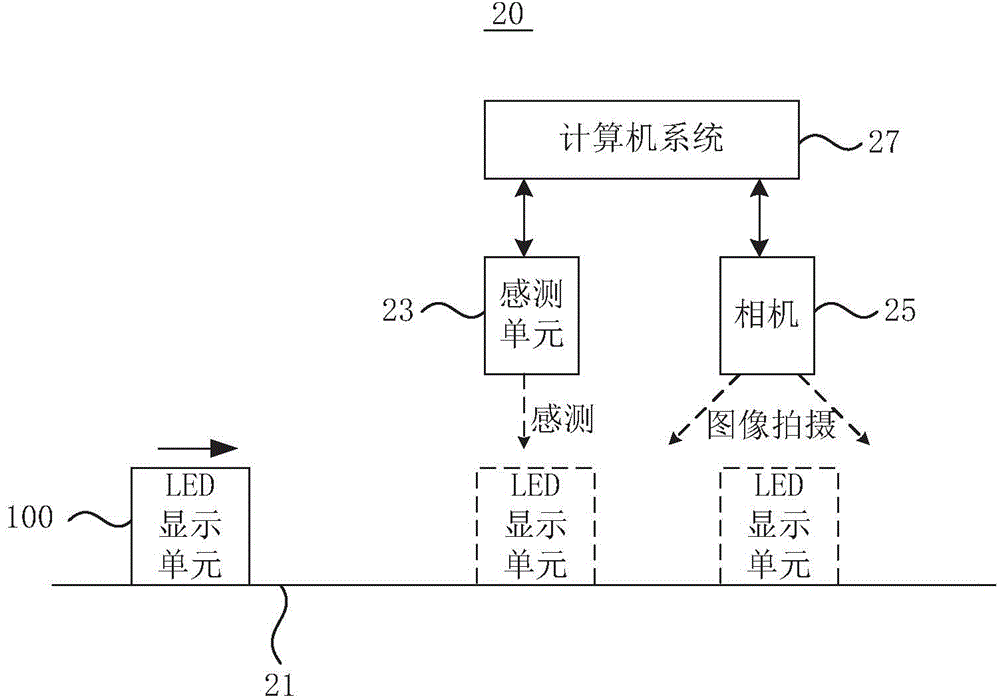

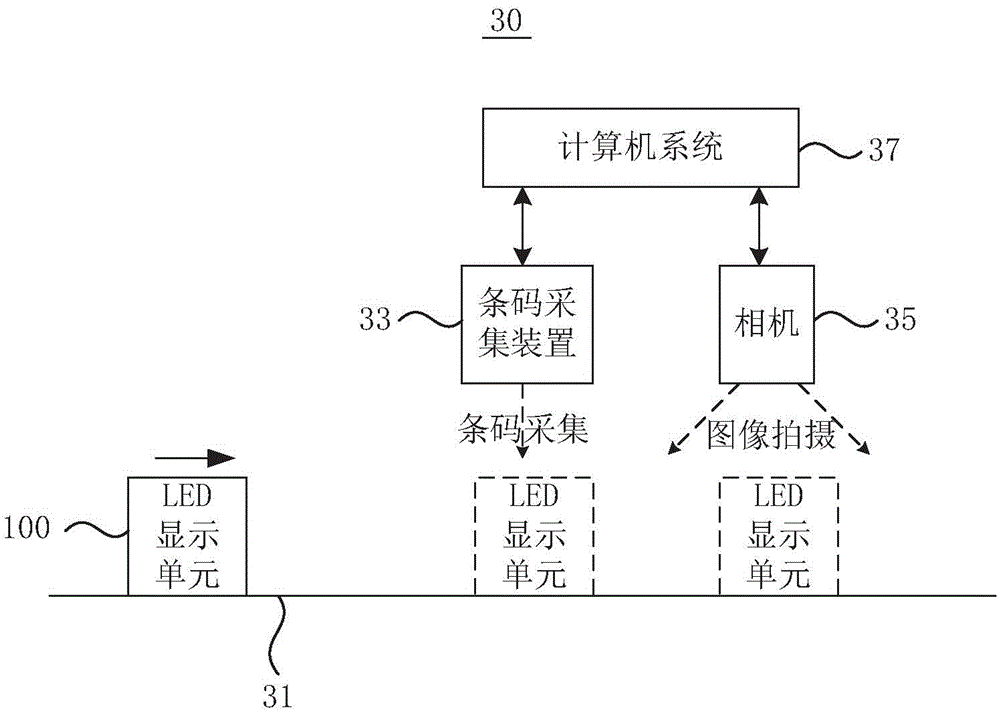

[0027] See figure 1 and figure 2 ,in figure 1 It is a flow chart of a method for detecting the uniformity of a pipelined LED display unit according to an embodiment of the present invention, figure 2 It is a schematic structural diagram of a pipelined LED display unit uniformity detection system according to an embodiment of the present invention. specifically:

[0028] A method for detecting the uniformity of a pipelined LED display unit provided by an embodiment of the present invention includes the following steps S11 , S13 , S15 and S17 . in,

[0029] Step S11: Obtain the serial number of the LED display unit at the preset position passing through the assembly line.

[0030] In this embodiment, on the automatic assembly line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com