Quality stability control method for Chinese prescription particle extraction process

A technology of traditional Chinese medicine formula granules and quality stability, which is applied in non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve the problems of incomplete extraction of active ingredients, long extraction time, uneven temperature, etc. Achieve the effect of ensuring process and quality stability, high content of active ingredients, and overcoming quality instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

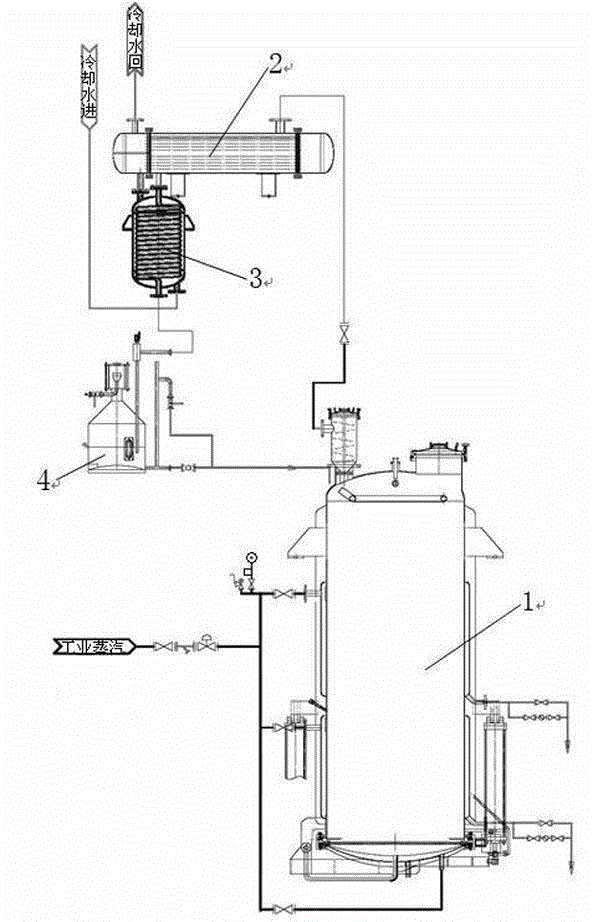

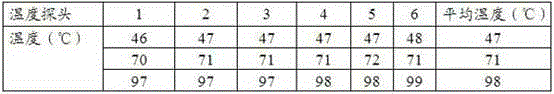

Embodiment 1

[0025] Take 100 Kg of honeysuckle decoction pieces and add 800 Kg of water to soak for 30 minutes, heat to boil and keep boiling for 2 hours. Heating is carried out through the extraction tank double-layer jacket segmental heating and tank bottom heating technology. After heating for 15 minutes, the extract boils. Real-time monitoring of the temperature and pressure in the extraction tank, the steam flow rate and the temperature of the cooling water entering and leaving the condenser, the design temperature difference between the cooling water entering and exiting is 12~18°C, the temperature setting in the tank is 96~102°C, and the pressure is 0~0.02 MPa. Arrange 6 temperature probes in the tank, which are respectively distributed at the upper end, middle end and bottom of the extraction tank near the jacket and near the center line. Cooling water inlet and outlet temperature difference Δt and cooling water inlet and outlet speed v It has a certain functional relationship. W...

Embodiment 2

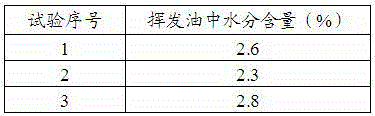

[0030] Take 100 Kg of Ligusticum chuanxiong and add 600 Kg of water to soak for 120 minutes, heat to boil and keep boiling for a few hours. The volatile oil of Rhizoma Chuanxiong is collected, and the oil-water interface detection technology is used for the oil-water separator to realize automatic oil-water separation. The oil-water interface detection technology can make the moisture content in the volatile oil lower than 3%. Get the obtained volatile oil and adopt gas chromatography to detect the moisture content in the volatile oil. The water content in the obtained volatile oil is shown in the table below.

[0031] Gas chromatography conditions: column: GDX101 column (3m × Φ4 mm); detector: thermal conductivity detector; injector temperature: 150 ~ 170 ℃; column temperature: 120 ~ 140 ℃; detector temperature: 140 ~160℃; carrier gas: helium; carrier gas flow: 40 ~ 50 mL / min.

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com