Non-contact vibrationless low-temperature solid interface thermal resistance testing arrangement

A test device and solid interface technology, applied in the field of thermophysical properties of high-temperature superconducting materials, can solve the problems of small independent sealed space and long experiment time, and achieve the effect of shortening the experiment period, reducing the impact, and reducing the time for vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

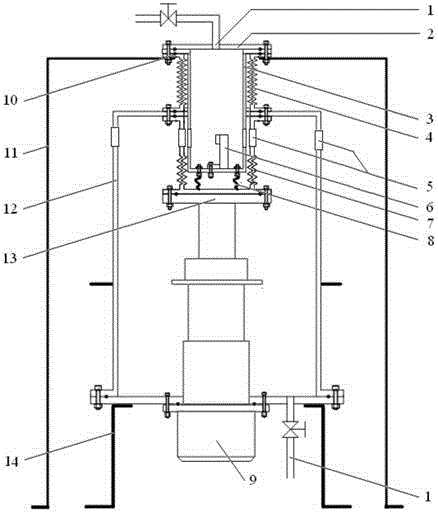

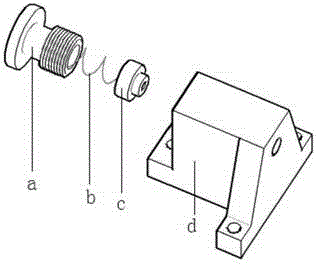

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

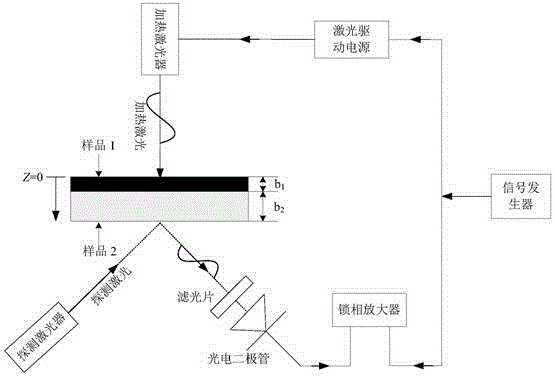

[0035] Such as figure 1Shown is a schematic diagram of the principle of measuring interface thermal resistance by laser photothermal method. During the experiment, the two sample pieces are stacked together and installed in the sample fixture. The signal generator generates a modulation signal of a certain frequency and divides it into two signals. One is used as a reference signal to input the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com