Anti-condensation radiant panel and manufacturing method thereof

A manufacturing method and technology of radiant panels, which are applied in heating methods, household heating, space heating and ventilation details, etc., can solve the structural characteristics of unavoidably thick air layers, increase heat transfer resistance, and reduce radiant panels for cooling. ability and other issues, to achieve the effect of good anti-condensation performance, improving cooling capacity and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

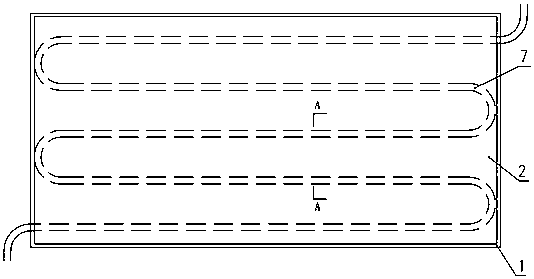

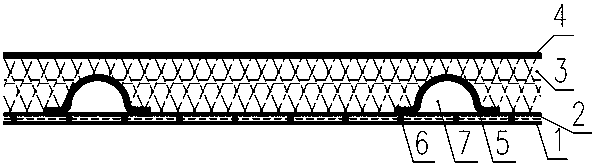

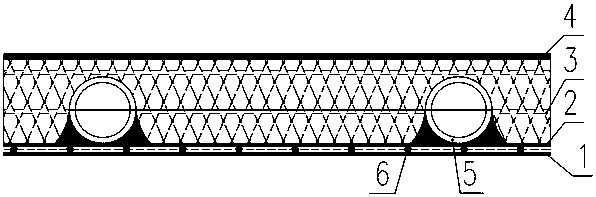

[0024] Such as figure 1 , 2 As shown, the radiant plate in Embodiment 1 of the present invention includes a metal panel 1 and a channel 7, wherein the channel 7 is made by welding a metal tube 5 with a semicircular cross section on the heat conducting plate 2, and the heat conducting plate 2 is very close to the metal panel 1. But it is not in contact with the metal panel 1, and a uniform air thin layer with a thickness of less than 1 mm is formed in the middle. The channel 7 and the heat conducting plate 2 are covered with an insulating material 3 . A support grid 6 is laid on the upper surface of the metal panel 1 . The support grid 6 is made of a material with poor thermal conductivity and is not easy to conduct heat. The heat conducting plate 2 is erected on the support grid 6 .

[0025] The metal pipe 5 has a semicircular cross section and is welded to the heat conduction plate 2 by welding process to form a chilled water flow and heat exchange channel. The heat transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com