Sealing ring for reaction kettle

A sealing ring and reaction kettle technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of easy damage to the lip of the seal, affect the sealing effect, and high cost of the sealing ring, so as to reduce the contact area and improve Compensation effect, effect of reducing frictional heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Please refer to figure 1 , figure 2 , a sealing ring for a reaction kettle, including a sealing ring body 1, the sealing ring body 1 includes an outer lip 11, an inner lip 12, an annular groove 13 is formed between the outer lip 11 and the inner lip 12 , the cross-section of the annular groove 13 is U-shaped, which also includes an elastic compensator, the elastic compensator is located in the annular groove 13 between the outer lip 11 and the inner lip 12, the inner lip 12 Multiple lips 14 are arranged on it.

[0025] In this embodiment, the elastic compensator is a U-shaped spring 2, the thickness of the outer lip 11 is greater than the thickness of the inner lip 12, and an annular groove 15 is provided on the outer side of the outer lip 11, and at the same time, the sealing The ring also includes an O-ring 3, and the O-ring 3 is arranged in the annular groove 15, so that during the sealing process, the sealing ring and the equipment are in closer contact to achiev...

Embodiment 2

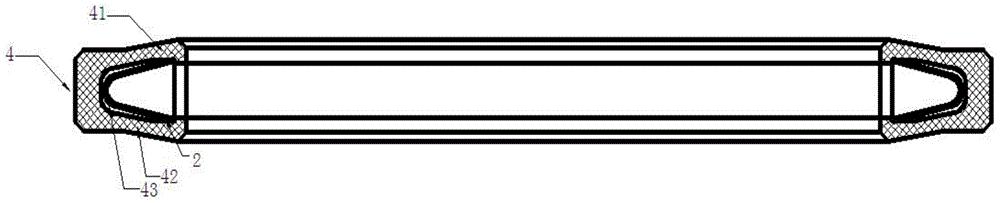

[0029] Please refer to image 3 , the difference between the second embodiment and the first embodiment is that the annular groove 13 in the first embodiment is rotated 90 degrees to the inner side of the sealing ring body 1 to obtain image 3 The surface view of the sealing ring of the second embodiment is shown, and the thickness of the outer lip 41 in this embodiment is equal to the thickness of the inner lip 42 . Other unmentioned components are the same as those described in Embodiment 1, and will not be repeated here.

Embodiment 3

[0031] Please refer to Figure 4 The difference between the third embodiment and the first embodiment is that the elastic compensator is a circular spring 6 , and the thickness of the outer lip 51 in this embodiment is equal to the thickness of the inner lip 52 . Other unmentioned components are the same as those described in Embodiment 1, and will not be repeated here.

[0032] In the above embodiments, the opening width T of the annular groove is smaller than the sectional diameter D of the elastic compensator to prevent the elastic compensator from falling out of the annular groove after installation, and the height of the outer lip is not lower than the height of the inner lip, that is The height of the outer lip is equal to or greater than that of the inner lip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com