Internal waverider-derived turbine base combined dynamic gas inlet adopting binary variable-geometry manner

A turbine-based combination and air inlet technology, which is used in jet propulsion devices, gas turbine devices, machines/engines, etc., can solve problems such as the inability to meet the working Mach number range, and achieve simple and reliable deformation, good airflow quality, and requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

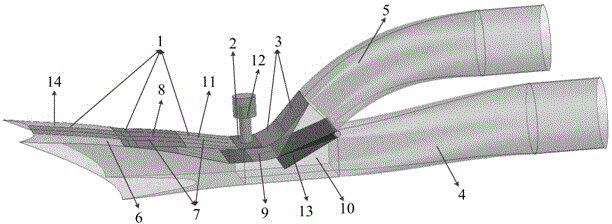

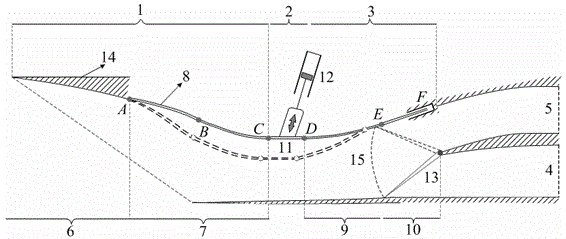

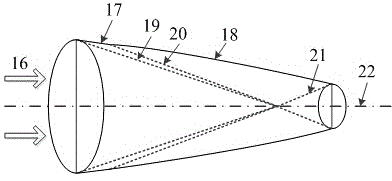

[0037] A variable geometry intake port is designed for the internal parallel TBCC combination power suitable for the working Mach number range of 0-4 and the transitional Mach number of 2.5. Since the maximum working Mach number is 4.0, a combination of a sub-combustion ramjet engine and a turbine engine is adopted. The inlet profile at the maximum working Mach number 4.0 is designed by using the inner waverider inlet method. Therefore, the design parameters of the ICFC basic flow field are selected: M1=4.0, M3=1.4, and the initial internal contraction angle is 10°. The design requirements for the shape of the inlet are: the outlet of the inlet is a regular rectangle with an aspect ratio of 1.6, and the center point of the flow field of the inlet is arranged at the center of the lower side of the rectangular inlet. Based on the basic profile of M4, a simple and adjustable variable geometry scheme is designed. attached figure 1 A three-dimensional schematic diagram of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com