Large mining height gob-side entry retaining method for thick coal seams

A technology of gob-side entry retaining and large mining height, which is applied in surface mining, mining equipment, earth-moving drilling and mining, etc., can solve the problems of difficult maintenance of gob-side entry retaining, high input of equipment and materials, and interference of safe mining of coal seams. Conducive to the maintenance of mining space, the maintenance of overall stability, and the effect of improving coal extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

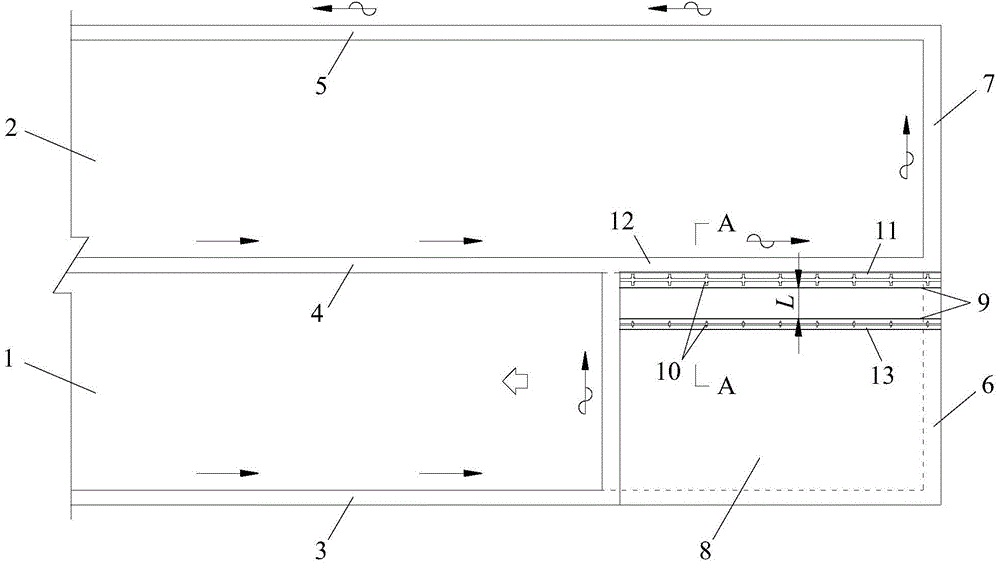

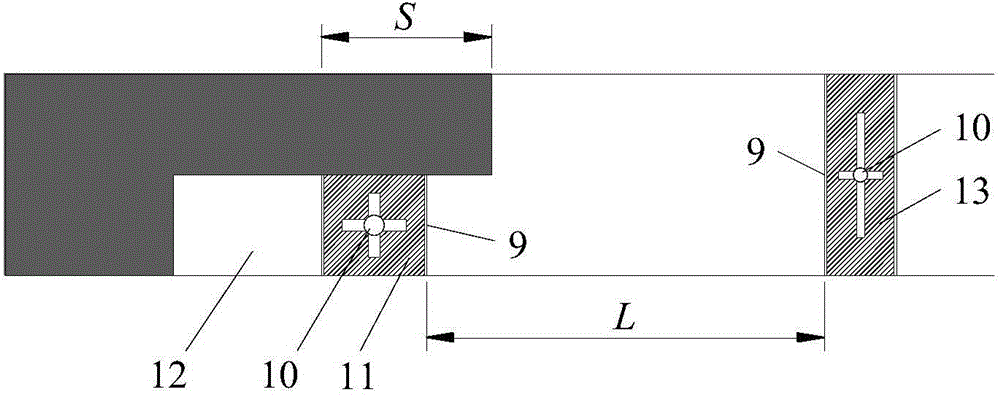

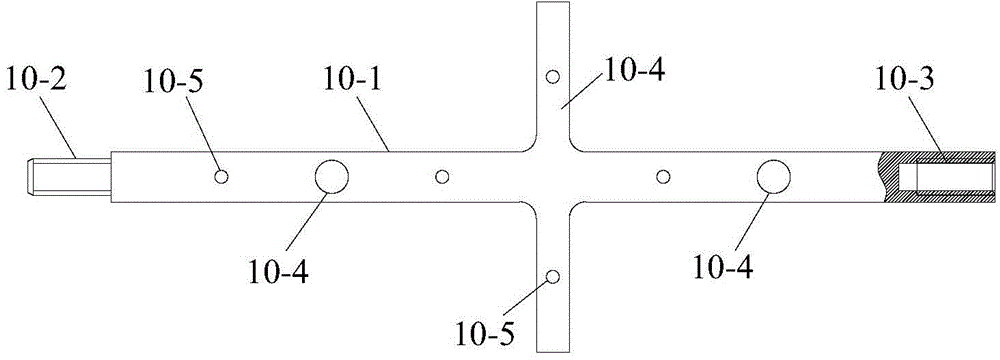

[0028] Such as figure 1 As shown, the thick coal seam large mining height gobside entry retaining method of the present invention, when mining the upper section coal mining face 1, first excavate the lower section coal mining face track lane 5 of the lower section coal mining face 2 And the cutout 7 of the coal mining face in the lower section, together with the transportation lane 3, the track lane 4 and the cutout 6 of the coal mining face 1 in the upper section, constitute the ventilation system of the coal mining face 1 in the upper section; In section coal mining face 1, roadside support wall 11 and pressure buffer wall 13 with built-in ventilation pipeline 10 are built along the edge of goaf 8, and a certain horizontal distance L is kept between the two walls. , forming a gob-side entry 12; when the coal mining face 2 in the lower section is mined, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com