Liquid storage equipment with cleaning device

A cleaning device and liquid storage technology, which is applied to water supply devices, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of elastic fatigue, discount of cleaning effect, and elastic fatigue of bristles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

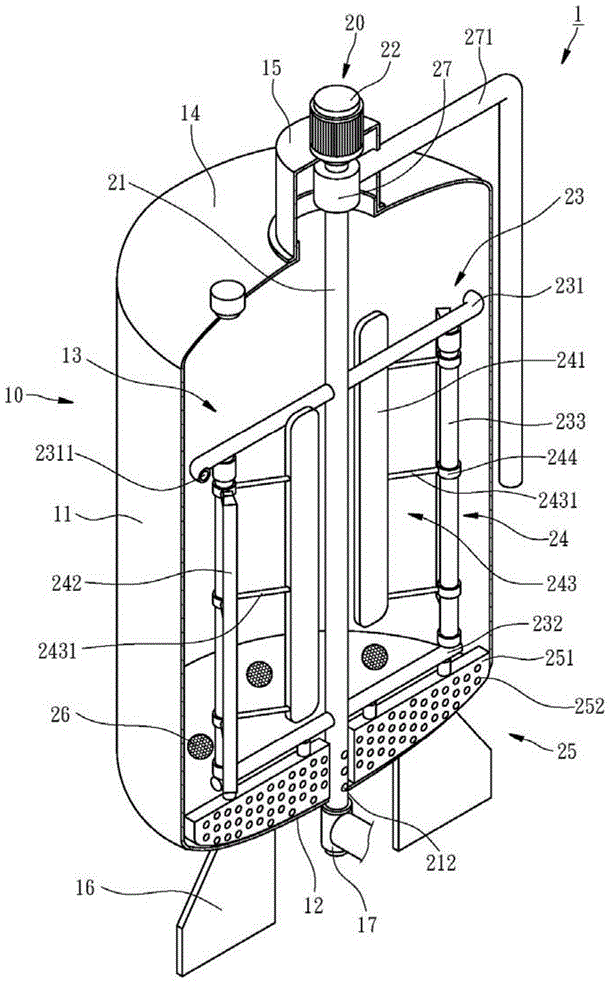

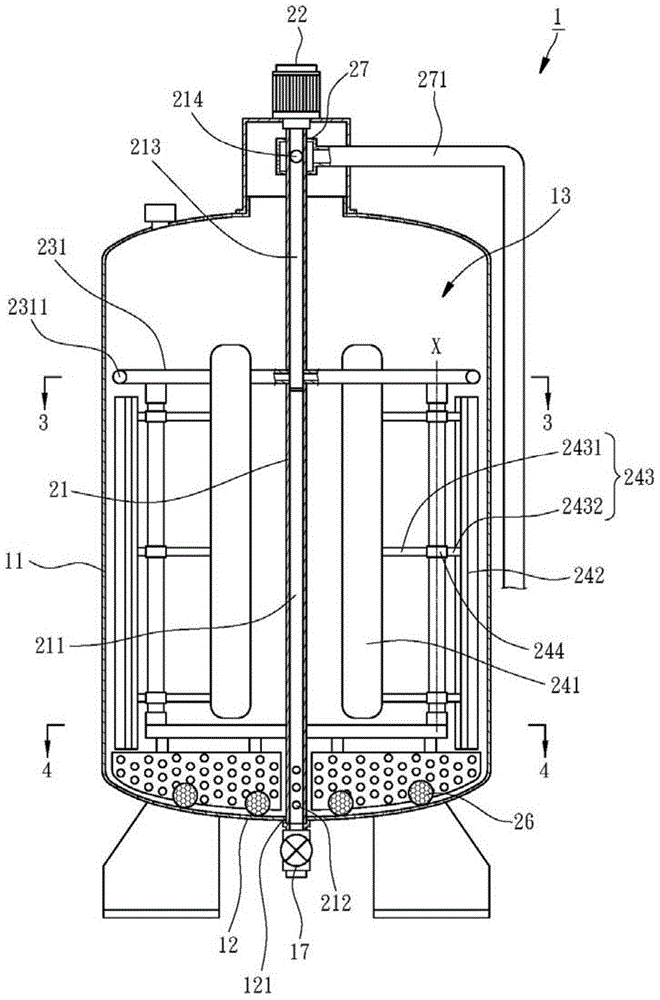

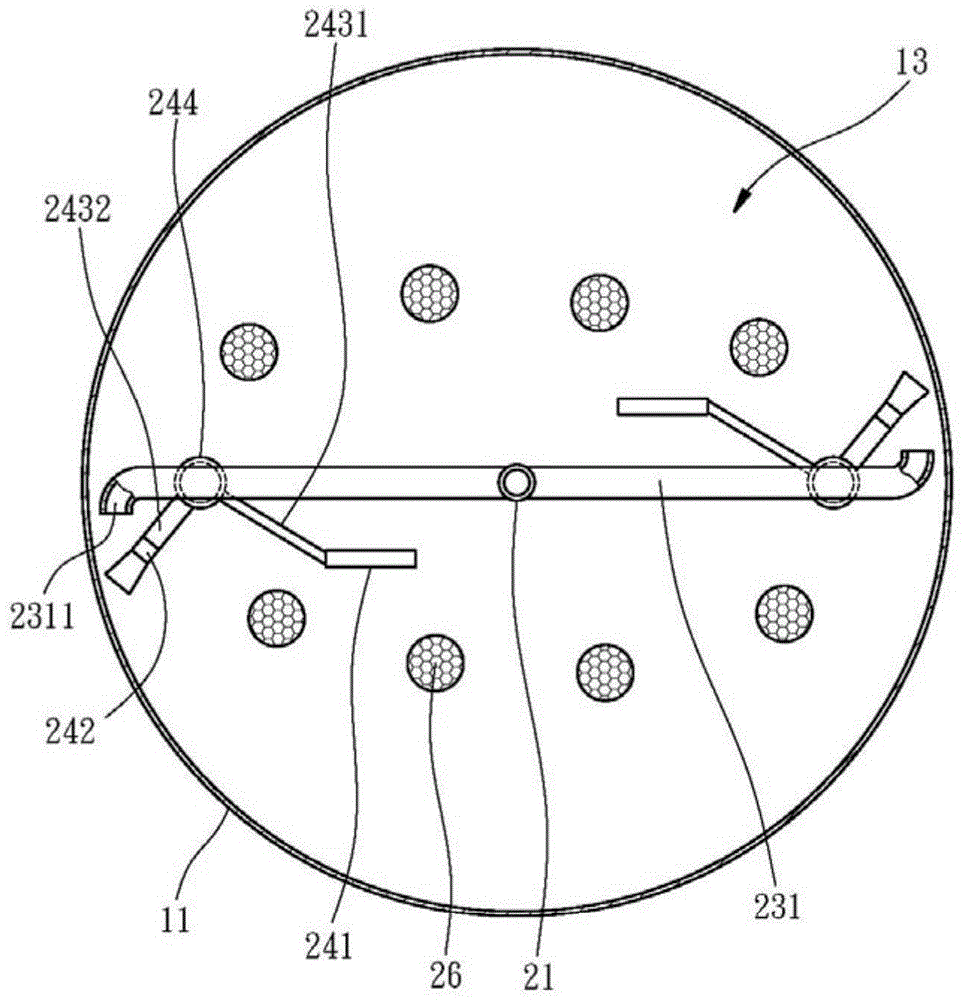

[0032] like Figure 1 to Figure 4 As shown, it is the first embodiment of the present invention. The liquid storage device 1 includes a cylinder body 10 and a cleaning device 20. The liquid storage device 1 is suitable for storing water or other liquids. One of the most common forms of the liquid storage device 1 is water tower.

[0033] The cylinder body 10 includes a peripheral wall 11 and a bottom wall 12 located at the bottom edge of the peripheral wall 11. A liquid storage space 13 is enclosed between the peripheral wall 11 and the bottom wall 12. The peripheral wall 11 is preferably designed to be cylindrical, but In fact, slight changes can still be made according to requirements, and the bottom wall 12 can be an arc surface, a plane or other irregular surfaces. In this preferred embodiment, the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com