Diesel hammer pile driver

A technology of pile driver and diesel, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem of noise of diesel pile driver, and achieve the effect of reducing noise emission and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

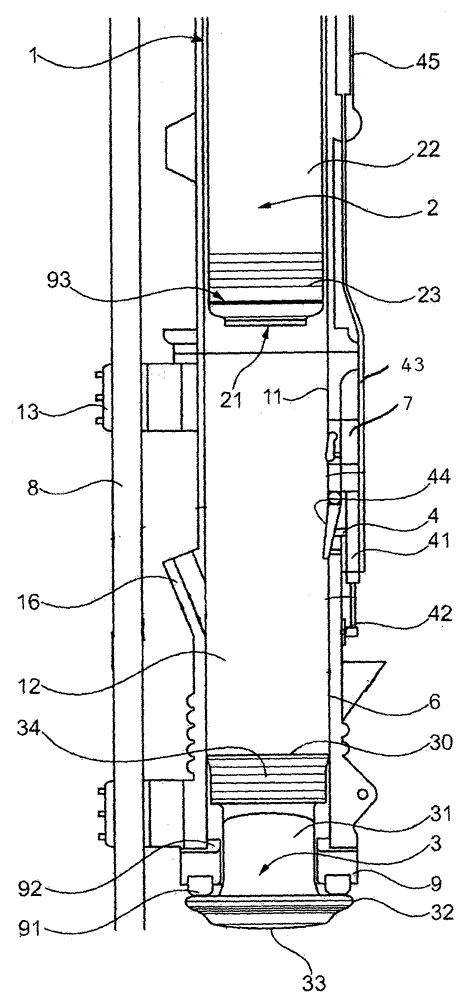

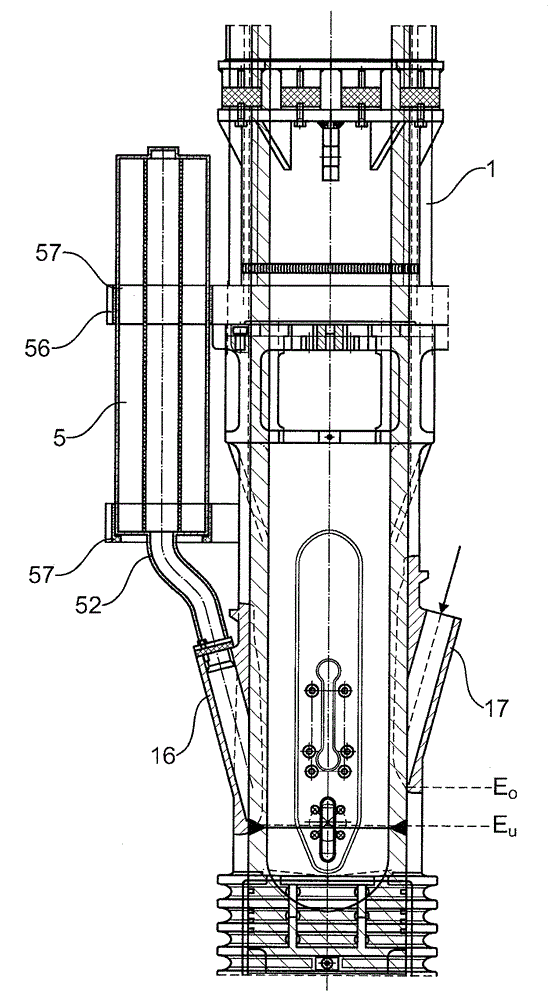

[0020] The diesel pile driver of the chosen embodiment comprises a cylinder 1 open on both sides, which may typically have a length of 3 to 8 meters and a diameter of 0.2 to 1.5 meters. A piston 2 is movably arranged in the cylinder 1 . A striker 3 coaxial therewith is movably engaged in the open lower end of the cylinder 1 . At the lower end of the cylinder 1 is fixed an annular bearing unit 9 in which a central rod section (Schaftabschnitt) 31 (which has an inner diameter relative to the cylinder 1 ) of the striker 3 is guided tightly and displaceably. reduced outer diameter). The diesel pile driver is mounted vertically displaceable along an intermediate piece 8 via guide carriages 13 arranged on the cylinder block 1 .

[0021] At the lower end of the rod section 31 is molded an impact plate (Schlagplatte) 32 located below the cylinder 1 , whose downwardly protruding lower limiting surface 33 cooperates with the upper end of the pile driving object to be pressed in during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com