Pre-chamber system for an internal combustion engine

A technology of pre-combustion chamber and internal combustion engine, applied in the field of pre-combustion chamber system and internal combustion engine, can solve problems such as insufficient progress and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

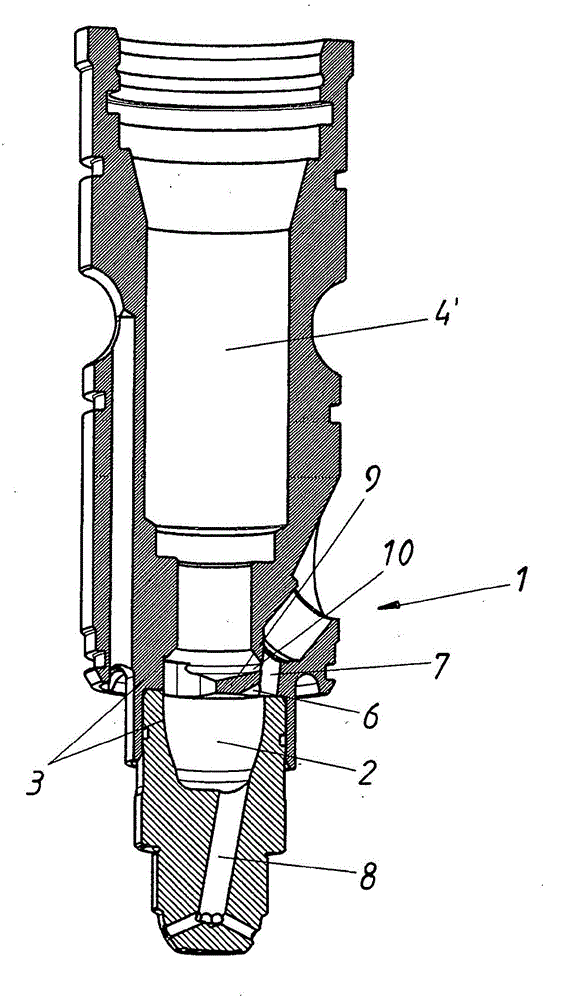

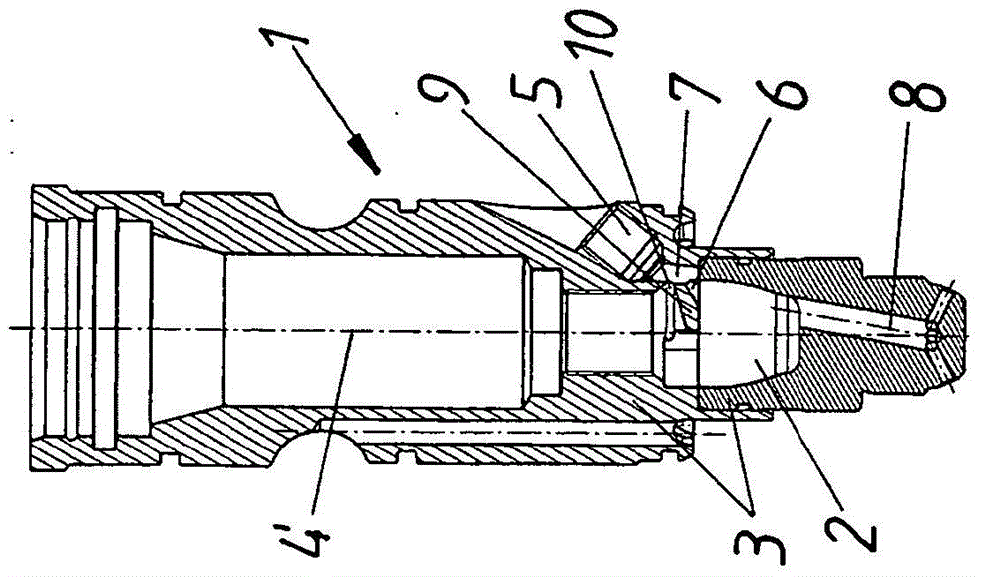

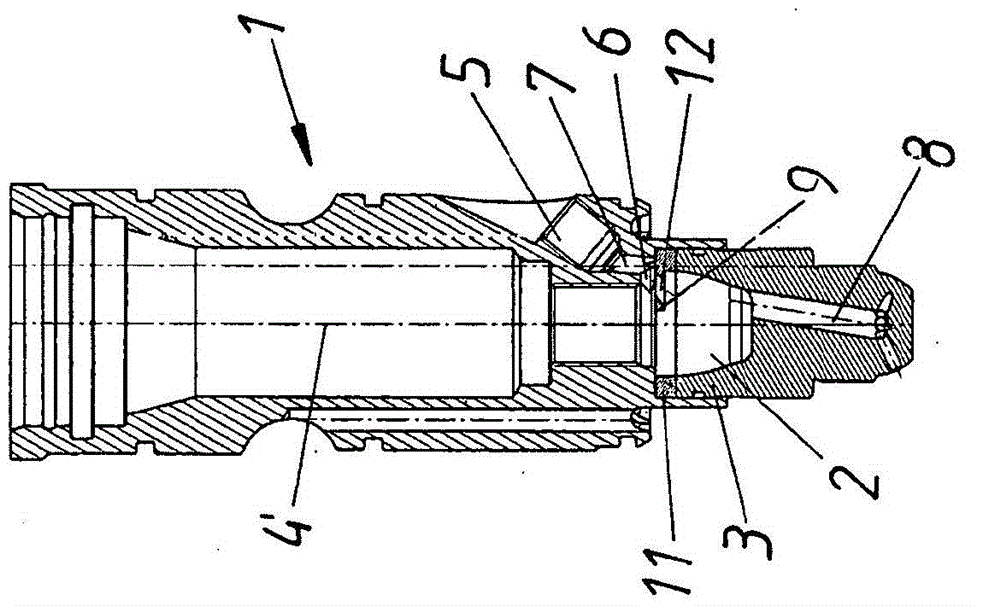

[0021] exist figure 1 A first embodiment of a prechamber system 1 according to the invention is shown in . In this case, the prechamber 2 is formed by a wall 3 and is connectable or connected in the assembled state via an ascending channel 8 to a combustion chamber (not shown) of the internal combustion engine. The ascending channel 8 opens into the prechamber 2 asymmetrically, thereby ensuring that a so-called tumble flow 14 is formed (see Figure 3b ).

[0022] In wellbore 4', the figure 1 A spark plug 4 (but see FIG. 3 ), not shown in FIG. 1 , is inserted into the prechamber system 1 . A gas channel 7 will be in figure 1 The introduction device 5 not shown in (but see Figure 2a ) is connected to the pre-chamber 2 via the inlet opening 6 . A guide device 9 is arranged in the prechamber system 1 adjacent to the inlet opening 6 . Above the guide means 9 , a hole 10 is provided in the wall 3 of the prechamber 2 , said hole establishing a connection to the gas channel 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com