Dacron and chinlon elasticizer

A texturing machine and polyester technology, applied in the fields of nylon texturing machine and polyester, can solve the problems of production efficiency impact, downtime maintenance, single texturing machine, etc., and achieve the effects of convenient handling, improving production efficiency and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

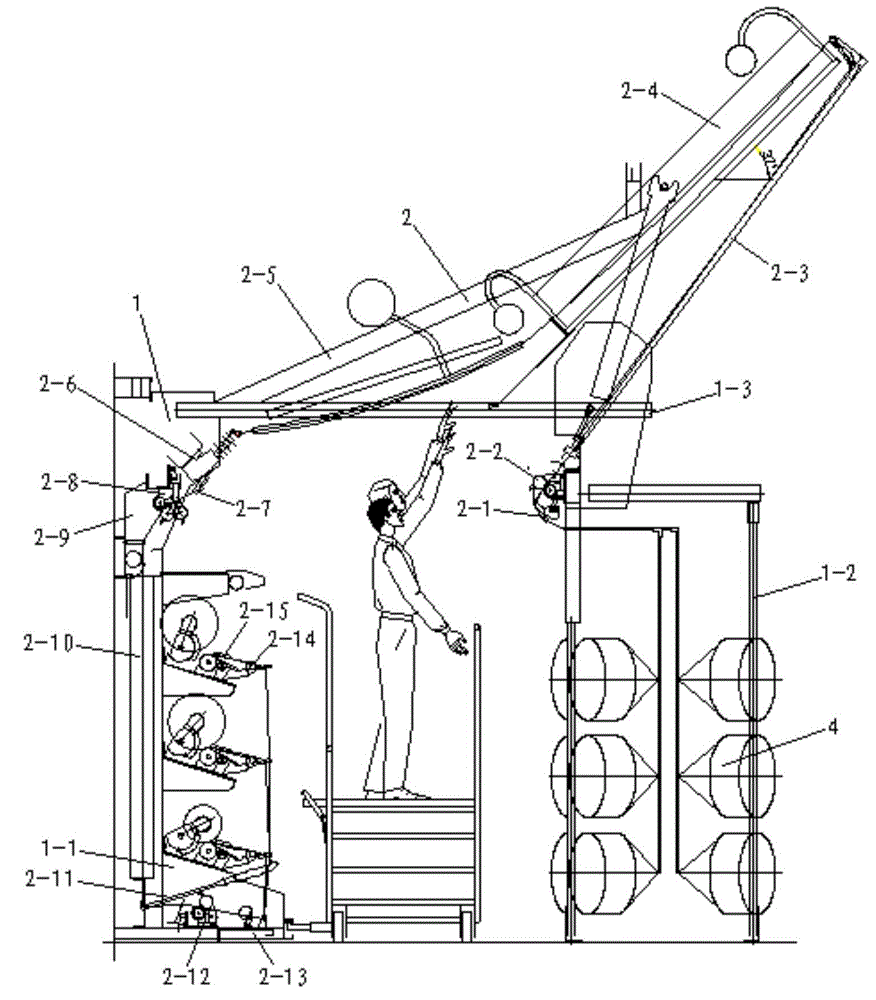

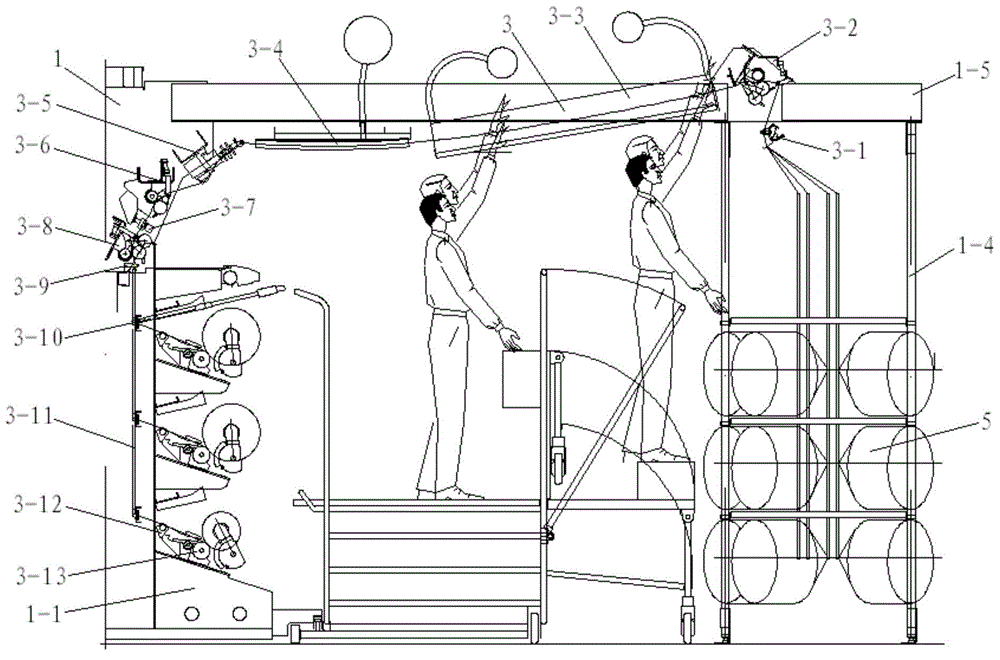

[0024] See figure 1 with figure 2 , The polyester and nylon texturing machine of this embodiment includes a frame 1, a polyester texturing assembly 2, a nylon texturing assembly 3 and an electric control assembly.

[0025] The polyester texturing assembly 2 and the nylon texturing assembly 3 are installed on both sides of the frame 1 respectively. Both the polyester textured component 2 and the nylon textured component 3 are provided with multiple groups, and are electrically connected with the electric control component 3 . The electric control component 3 can independently control the polyester texturing component 2 or the nylon texturing component 3 on one side and one spindle. Twelve groups are provided for the polyester stretching component 2 and the nylon stretching component 3 . Frame 1, polyester textured component 2, nylon textured component 3 and electric control components all adopt a modular and assembled structure.

[0026] The frame 1 includes a central fram...

Embodiment 2)

[0032] This embodiment is basically the same as Embodiment 1, except that this embodiment does not include the nylon texturizing component 3 . Both sides of the frame 1 are equipped with a polyester texturing assembly 2, and only the polyester is texturized.

Embodiment 3)

[0034] This embodiment is basically the same as Embodiment 1, except that this embodiment does not include the polyester stretching component 2 . Both sides of the frame 1 are equipped with nylon texturing components 3, which only texturize the nylon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com