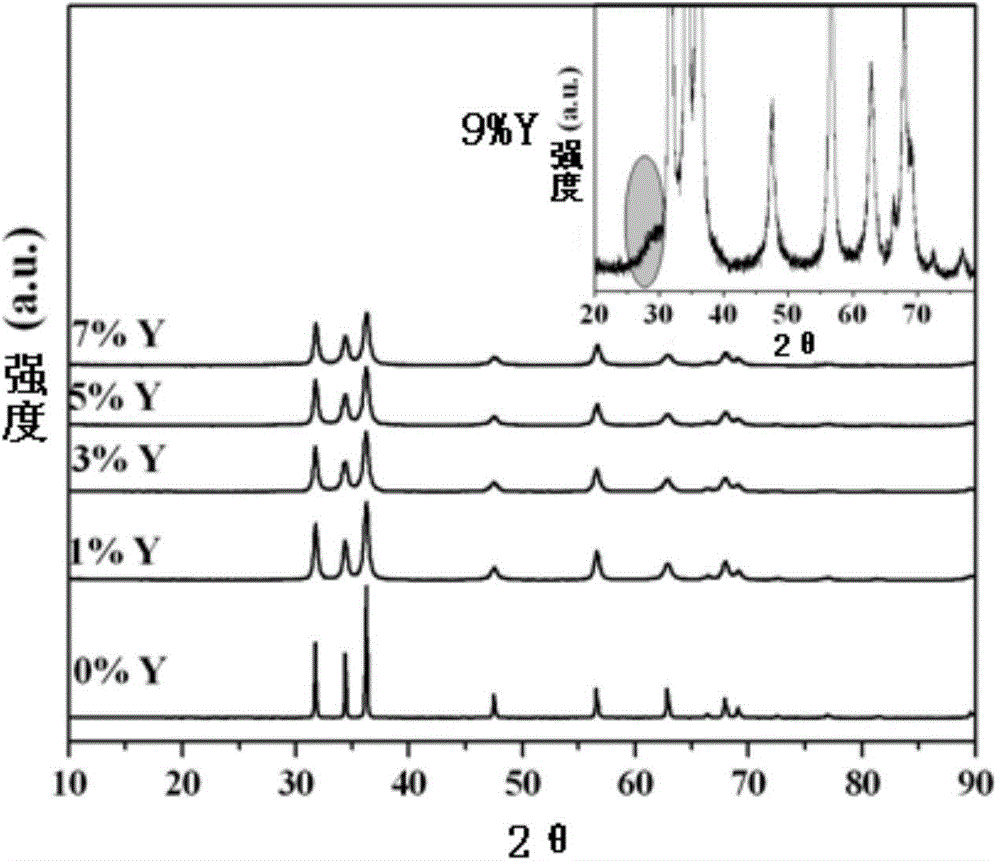

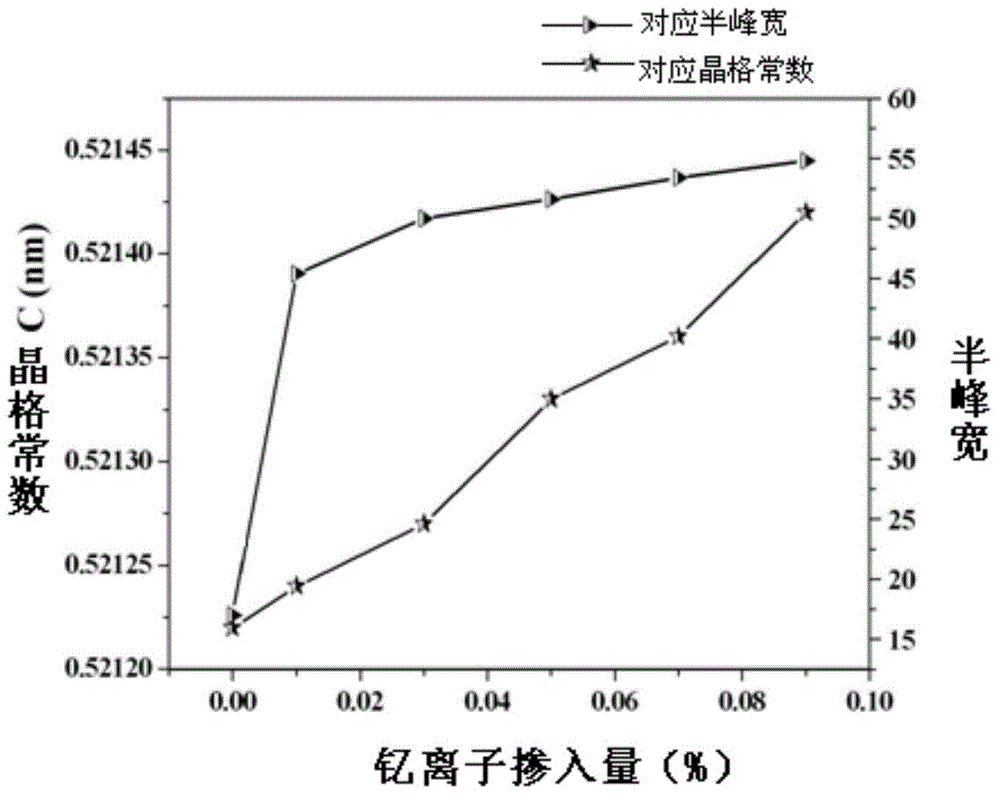

Application of yttrium ions in enhancing ultraviolet emission intensity of ZnO nanomaterial

A technology of nanomaterials and emission intensity, applied in luminescent materials, chemical instruments and methods, etc., to achieve the effects of simple operation, low temperature and easy reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the zinc oxide nanomaterial of the present embodiment comprises:

[0032] Step 1: Prepare respectively a zinc nitrate solution with a molar concentration of 0.1mol / L, a yttrium nitrate solution with a molar concentration of 0.1mol / L, and a citric acid solution with a molar concentration of 0.3mol / L, and magnetically stir the three solutions for 30 minutes respectively , to fully dissolve the reactants;

[0033] Step 2: Measure 60 mL of zinc nitrate solution with a molar concentration of 0.1 mol / L and 60 mL of a citric acid solution with a molar concentration of 0.3 mol / L for mixing; the doping concentration of yttrium ions is 0% molar concentration;

[0034] Step 3: Magnetically stir the solution mixed in step 2 for 3 hours to form a sol, put the sol in an oven at 80°C and keep it warm for 12 hours to form a xerogel, then put the xerogel in an oven at 130°C Medium heat preservation for 5 hours to make it dehydrated and puffed;

[0035] Step 4...

Embodiment 2

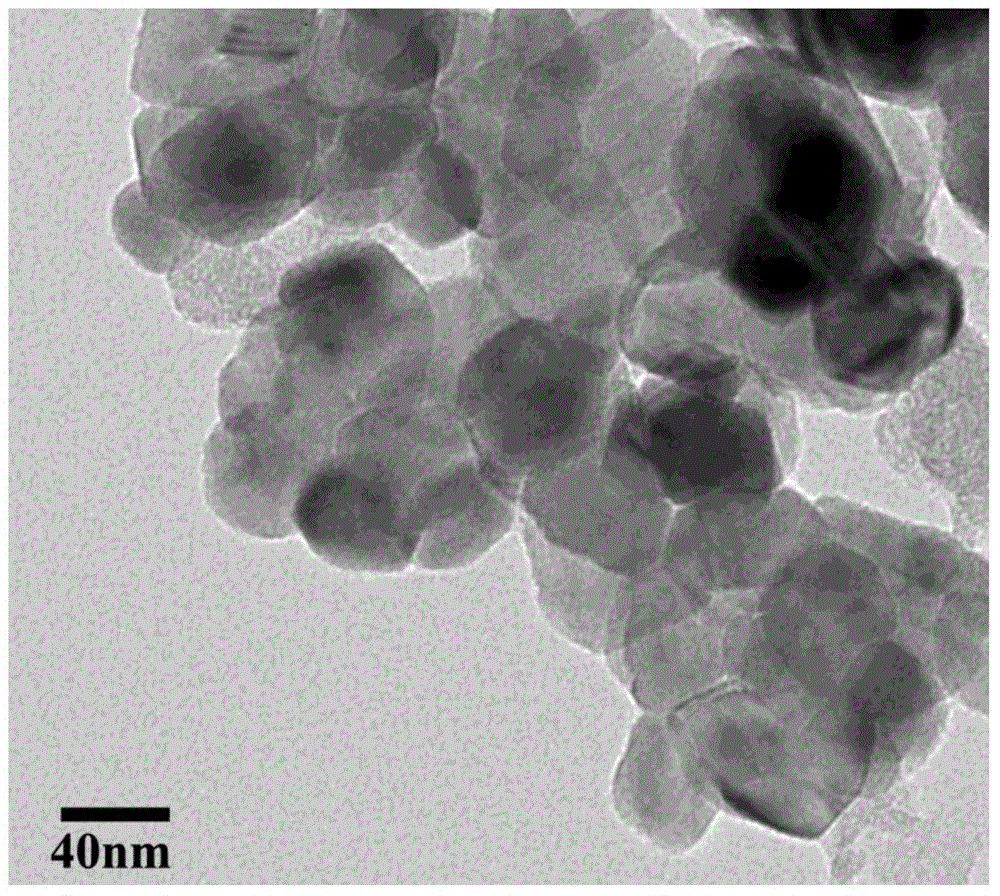

[0037] This embodiment is different from Example 1 in that: 59.4 mL of zinc nitrate solution with a molar concentration of 0.1 mol / L, 0.6 mL of yttrium nitrate solution with a molar concentration of 0.1 mol / L and 59.4 mL of a molar concentration of 0.3 mol / L were measured respectively. L citric acid solution was mixed; the particle size of the zinc oxide nanomaterial obtained in this embodiment was 40-60 nm, and the doping concentration of yttrium ions in this embodiment was 1% molar concentration.

Embodiment 3

[0039]The difference between this embodiment and Example 1 is that: 58.2 mL of zinc nitrate solution with a molar concentration of 0.1 mol / L, 1.8 mL of yttrium nitrate solution with a molar concentration of 0.1 mol / L, and 58.2 mL of a yttrium nitrate solution with a molar concentration of 0.3 mol / L were measured respectively. L citric acid solution was mixed; the particle size of the zinc oxide nanomaterial obtained in this embodiment was 40-60 nm, and the doping concentration of yttrium ions in this embodiment was 3% molar concentration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com