Blue light organic electroluminescent material, preparation method and applications thereof

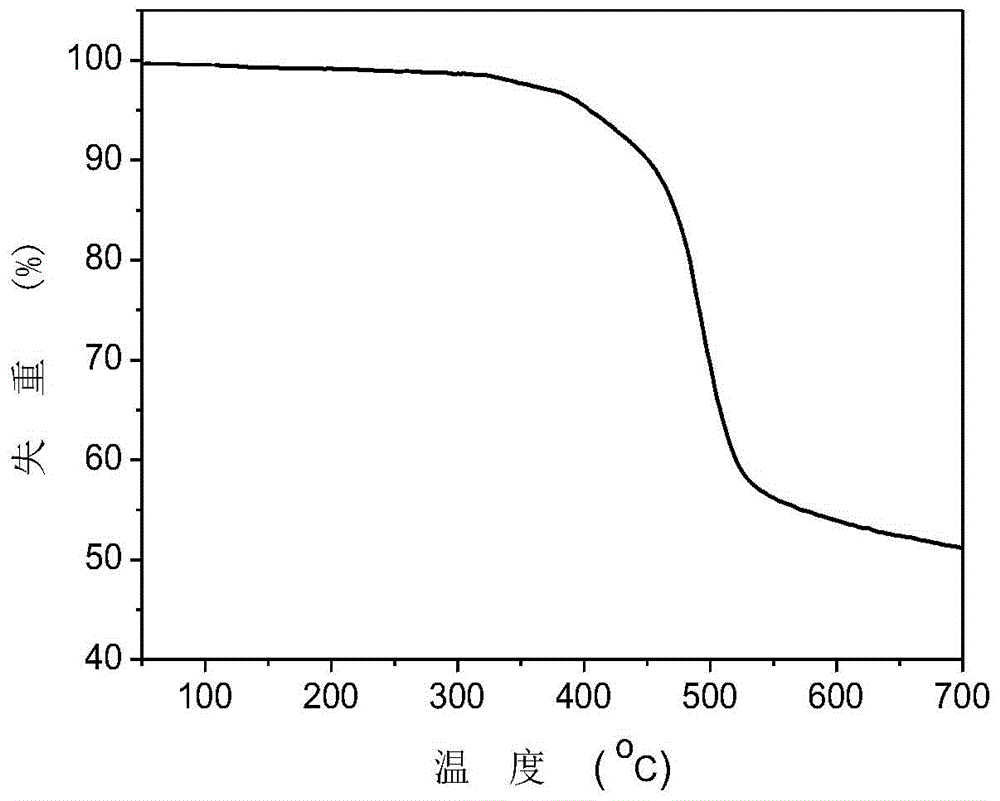

A luminescent and electromechanical technology, applied in luminescent materials, organic chemistry, chemical instruments and methods, etc., to achieve high fluorescence quantum yield, good thermal stability, and high device luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

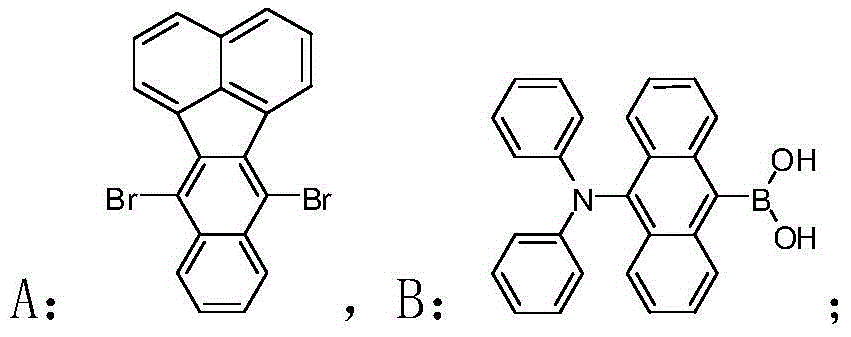

[0036] Example 1: The blue-light organic electroluminescent material of this example, that is, 10,10'-(benzo[k]fluoranthene-7,12-diyl)bis(N,N-diphenylanthracene-9- Amine), the preparation steps are as follows:

[0037]

[0038] Under the protection of argon, 7,12-dibromobenzo[k]fluoranthene (82mg, 0.2mmol), 10-(diphenylamine) anthracene-9-boronic acid (156mg, 0.4mmol) were added to a 10ml toluene In the flask of the solvent, after fully dissolving, potassium carbonate (2mL, 2mol / L) solution was added into the flask, vacuumed to remove oxygen and filled with argon, then added bistriphenylphosphine palladium dichloride (5.6mg, 0.008 mmol); the flask was heated to 120°C for Suzuki coupling reaction for 24h. The reaction was stopped and cooled to room temperature, the reaction solution was extracted with dichloromethane several times and the organic phase was combined. After the organic phase was dried over anhydrous magnesium sulfate and spin-dried, the crude product was obta...

Embodiment 2

[0040] Example 2: The blue-light organic electroluminescent material of this example has a structure of 10,10'-(benzo[k]fluoranthene-7,12-diyl)bis(N,N-diphenylanthracene- 9-amine), the preparation steps are as follows:

[0041]

[0042]Under the protection of mixed gas of nitrogen and argon, 7,12-dibromobenzo[k]fluoranthene (123mg, 0.3mmol), 10-(diphenylamine)anthracene-9-boronic acid (257mg, 0.66mmol) and Add 15mL tetrahydrofuran into a 50mL two-neck bottle, fully dissolve it, and then pass in a mixture of nitrogen and argon to exhaust the air for about 20 minutes, then add tetrakistriphenylphosphine palladium (4mg, 0.003mmol) into it, and then add it after fully dissolving Sodium bicarbonate (3mL, 2mol / L) solution. Then, the mixed gas of nitrogen and argon was exhausted for about 10 minutes, and the two-neck flask was added to 70°C for Suzuki coupling reaction for 48 hours. The reaction was stopped and cooled to room temperature, the reaction solution was extracted with...

Embodiment 3

[0043] Example 3: The blue-light organic electroluminescent material of this example has a structure of 10,10'-(benzo[k]fluoranthene-7,12-diyl)bis(N,N-diphenylanthracene- 9-amine), the preparation steps are as follows:

[0044]

[0045] Under nitrogen protection, 7,12-dibromobenzo[k]fluoranthene (123mg, 0.3mmol), 10-(diphenylamine)anthracene-9-boronic acid (280mg, 0.72mmol), palladium acetate (3.5mg ,0.015mmol) and tri(o-methylphenyl)phosphine (21mg, 0.06mmol) were added to a flask filled with 12mL of N,N-dimethylformamide, and potassium carbonate (3mL, 2mol / L) solution, followed by passing nitrogen into the flask to exhaust the air for about 30 minutes; heating the flask to 130° C. for Suzuki coupling reaction for 12 hours. The reaction was stopped and cooled to room temperature, the reaction solution was extracted with dichloromethane several times and the organic phase was combined. After the organic phase was dried over anhydrous magnesium sulfate and spin-dried, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com