Method and equipment for preparing continuous fiber-reinforced polyether-ether-ketone composite material prepreg tape

A technology of continuous fiber and polyether ether ketone, which is applied in the field of composite material reinforcement preparation, can solve the problems of easy damage of fibers and weak interfacial interaction of resin matrix, etc., and achieve the effects of reducing melt viscosity, improving interfacial interaction, and improving impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] To prepare a carbon fiber content of 53% reinforced polyether ether ketone composite material prepreg tape, the steps are as follows:

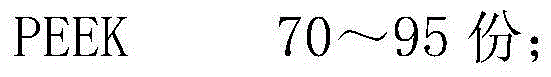

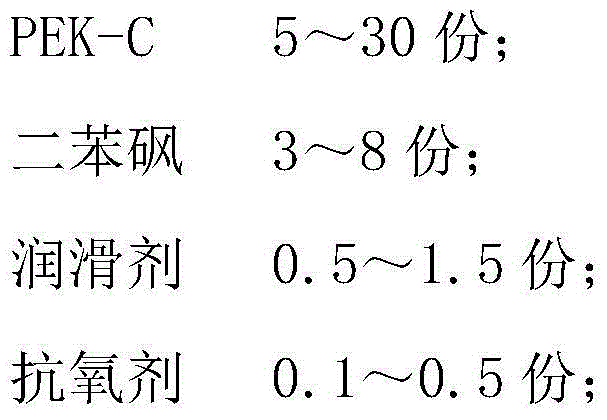

[0081] 1) The parts by weight ratio of each raw material in the mixed batch is as follows:

[0082]

[0083] Among them, polyetheretherketone (PEEK) is selected from Victrex PEEK / 450G;

[0084] Among them, phenolphthalein PEK (PEK-C) is produced by Xuzhou Chemical Factory, and its intrinsic viscosity is 0.81;

[0085] Among them, diphenyl sulfone (DPS) is produced by Suzhou Yinsheng Chemical Company;

[0086] 2) mix the raw materials evenly;

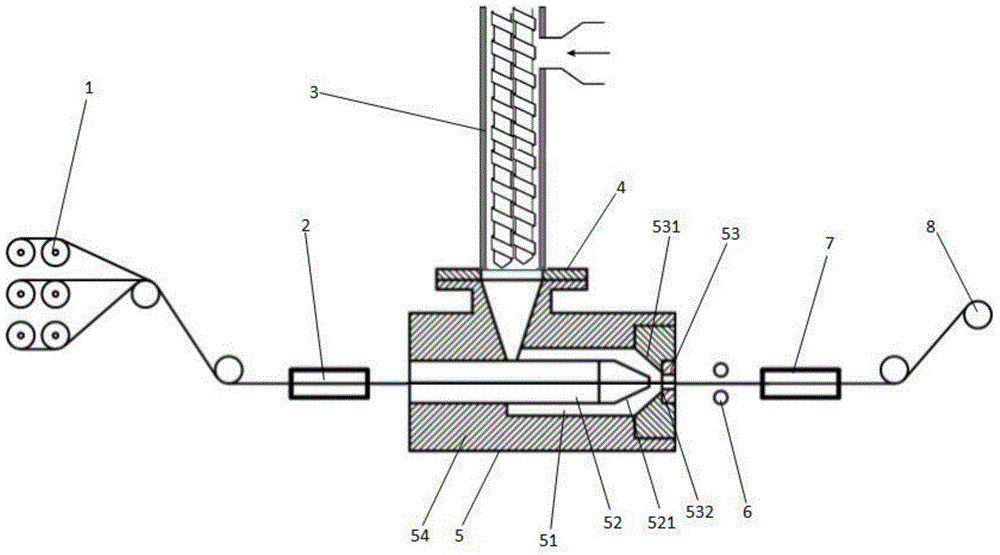

[0087] 3) Molding on the manufacturing equipment: the mixed ingredients enter the twin-screw extruder 3 through the hopper (the temperature of the melting section is 380° C.), and after melting, the modified PEEK resin melt enters the resin flow channel 51 of the impregnation mold 5, continuously The fiber bundle is drawn forward by the winding device 8; the melt extrudes the continuous fibe...

Embodiment 2

[0091] To prepare a carbon fiber content of 30% reinforced polyether ether ketone composite material prepreg tape, the steps are as follows:

[0092] 1) The parts by weight ratio of each raw material in the mixed batch is as follows:

[0093]

[0094] 2) mix the raw materials evenly;

[0095] 3) molding is carried out on the manufacturing equipment; the difference between the equipment parameters of the present embodiment and embodiment 1 is that the tension of the tension controller of the yarn dividing device 1 is controlled at 30N, and the screw speed of the twin-screw extruder 3 is 45rpm / min , the winding speed of the winding device 8 is 7.5m / min; in addition, the temperature of the heating box is 300°C, the temperature of the twin-screw extruder is 400°C, and the temperature of the dipping mold is 390°C;

[0096] 4) After cooling the prepreg tape coming out of the impregnation mold 5, it is wound up on the winding device;

[0097] 5) The wound prepreg tape is removed...

Embodiment 3

[0103] Preparation of prepreg tape of polyether ether ketone composite material with 21% carbon fiber content

[0104] 1) The parts by weight ratio of each raw material in the mixed batch is as follows:

[0105]

[0106] 2) mix the raw materials evenly;

[0107] 3) molding is carried out on the manufacturing equipment; the difference between the equipment parameters of the present embodiment and embodiment 1 is that the tension of the tension controller of the yarn dividing device 1 is controlled at 5N, and the screw speed of the twin-screw extruder is 100rpm / min, and the coil The winding speed of the winding device 8 is 5m / min; in addition, the temperature of the heating box is 320°C, the temperature of the twin-screw extruder is 350°C, and the temperature of the dipping mold is 345°C;

[0108] 4) After cooling the prepreg tape coming out of the impregnation mold 5, it is wound up on the winding device;

[0109] 5) The wound prepreg tape is removed from the winding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com