Biological enhanced nitrogen removal treatment method of degradation-resistant high-concentration organic industrial wastewater

A technology for industrial wastewater and biological enhancement, applied in natural water treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of secondary pollution, high operating costs, and difficulty in control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

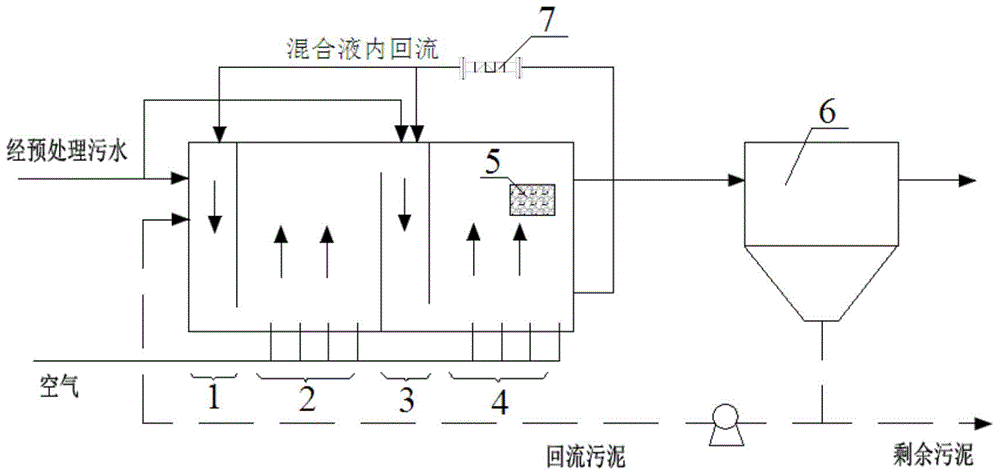

[0029] In this embodiment, the sewage is first homogenized (to make the waste water evenly mixed), and then subjected to secondary precipitation after passing through the secondary anoxic-aerobic + biofilm component reactor.

[0030] The processing system used in this embodiment is such as figure 1 As shown, the first-level anoxic tank 1, the first-level aerobic tank 2, the second-level anoxic tank 3, and the second-level aerobic tank 4 are connected in sequence, 0.3 meters below the liquid surface of the second-level aerobic tank 4 A biomembrane module 5 with a thickness of 0.5m is added at the place, covering an area of 1 / 3 of the total length of the tank and 9 / 10 of the total width, located at the end of the tank, and the distance between the upper surface of the module and the sewage surface is 0.3 meters. The outlet water of the second-stage aerobic tank 4 is connected to the second settling tank section 6. The effluent of the second-stage aerobic tank 4 is respectively re...

Embodiment 2

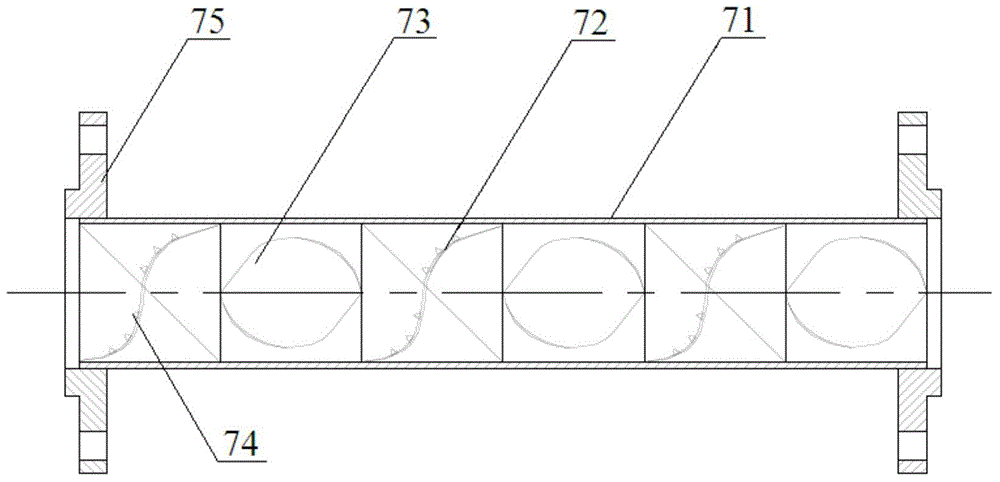

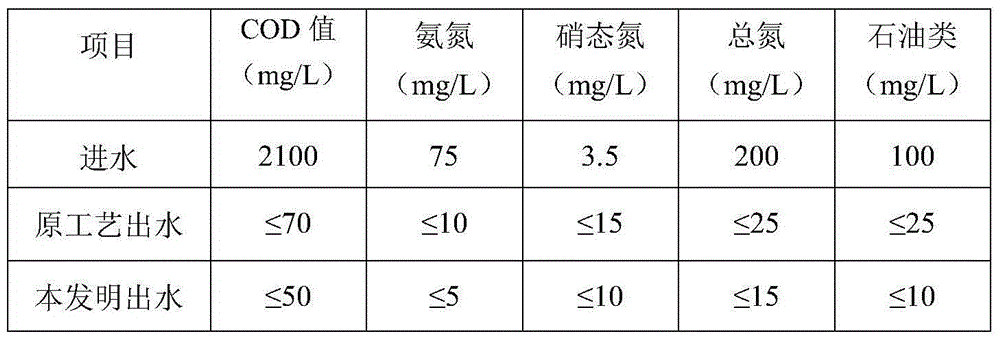

[0038] The total nitrogen and COD of a coal-to-gas wastewater of a coal chemical plant cannot meet the standards stably using the original treatment technology. After adopting this technical transformation, the main process route is as follows: First, the sewage passes through the anaerobic digestion section to remove a large amount of organic pollutants, so that the influent COD is maintained at about 500mg / L, and then enters the first level at a ratio of 7:3. , The secondary anoxic tank, and then the mud-water mixture in the same proportion passes through the tubular sludge crusher and then enters the anoxic tanks at all levels. The sludge is sheared and broken by strong turbulence, and the surface of the flocs is destroyed, releasing organic matter such as polysaccharides and proteins. , To supplement the organic carbon source required for denitrification in anoxic tanks to strengthen denitrification, degradation of refractory organic matter and reduction of sludge source. T...

Embodiment 3

[0048] A treatment method for bio-enhanced denitrification of refractory high-concentration organic industrial wastewater. The treatment system used is such as figure 1 As shown, the first-level anoxic tank 1, the first-level aerobic tank 2, the second-level anoxic tank 3, and the second-level aerobic tank 4 are connected in sequence, 0.3 meters below the liquid surface of the second-level aerobic tank 4 A biomembrane module 5 with a thickness of 0.5m is added at the place, covering an area of 1 / 3 of the total length of the tank and 9 / 10 of the total width, located at the end of the tank, and the distance between the upper surface of the module and the sewage surface is 0.3 meters. The outlet water of the second-stage aerobic tank 4 is connected to the second settling tank section 6. The effluent of the second-stage aerobic tank 4 is respectively returned to the first-stage anoxic tank 1 and the second-stage anoxic tank 3 through the return pipeline. A tubular sludge crusher 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com