Composite material wing integral molding technological method and composite material wing integral molding tool

A composite material and integral molding technology, which is applied in the field of composite material wing integral molding process method and tooling, can solve the problems of small overall size, limited internal operating space, and inability to accurately guarantee the inner and outer profile of the product and the thickness of the layup. Accurate size, stable and reliable quality of molded products, and good internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

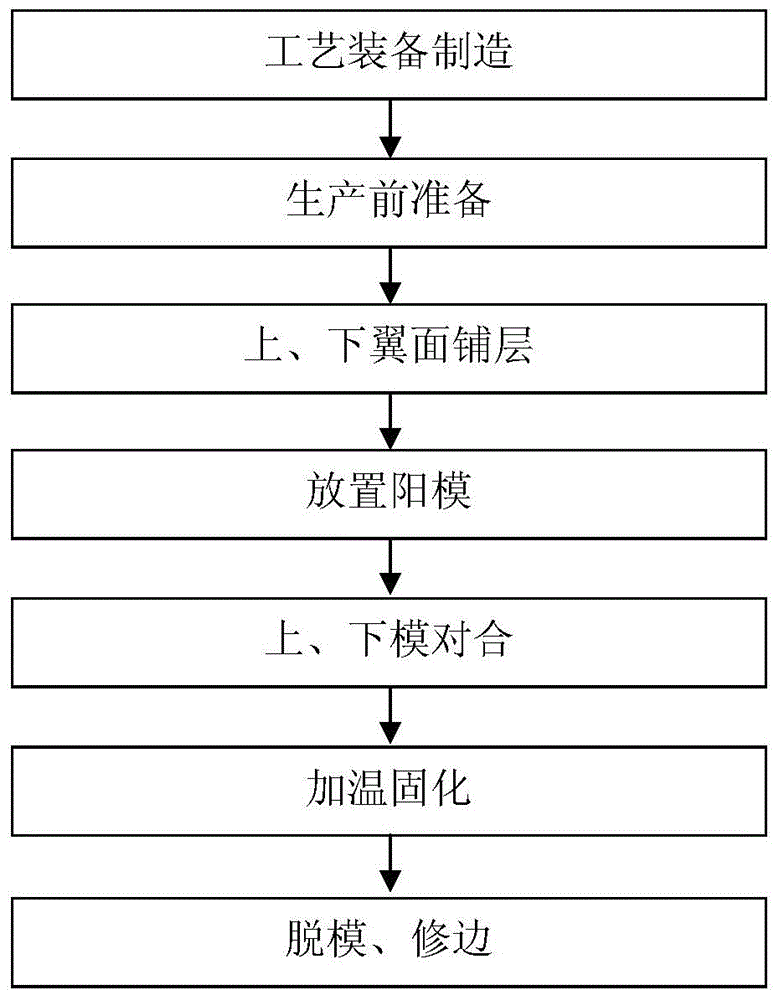

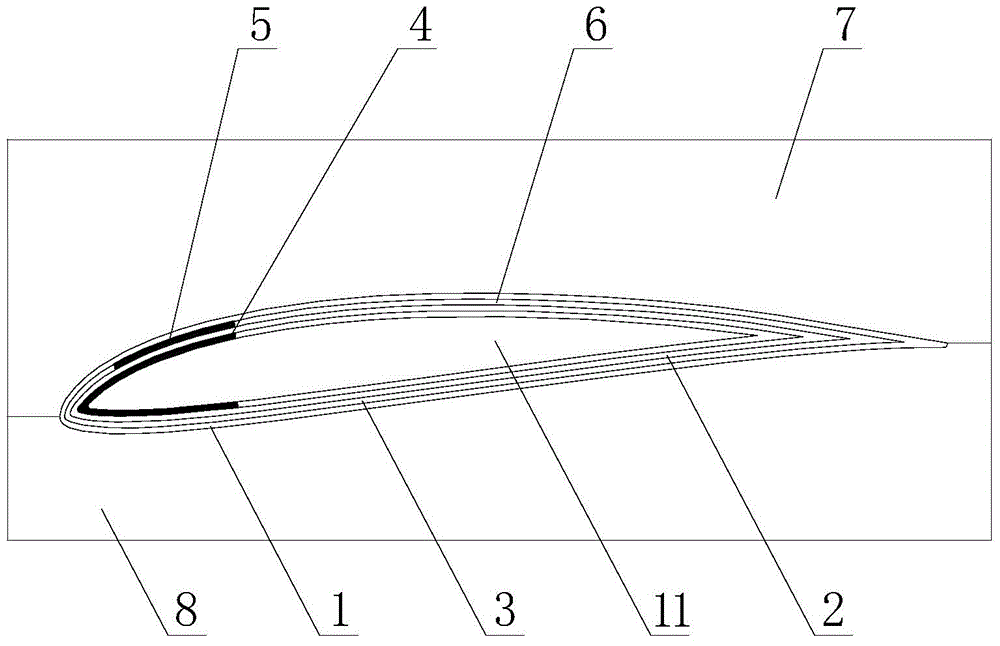

[0025] This embodiment is a composite material wing integral molding process and tooling.

[0026] This embodiment is used in the overall molding of a certain type of smaller-sized composite material wing. The length of the composite material wing is 1.65 meters, the maximum chord length is 0.26 meters, and the maximum airfoil height is 24 mm. Due to the small size of the composite airfoil parts and the narrow internal space, it is difficult to carry out the paving operation from the inside; however, in the technical requirements of the product, there are high requirements for the accuracy of the inner and outer profiles of the wing and the thickness of the parts, and the requirements must be integrated Molding, such as using conventional molding methods, it is difficult to meet the above technical requirements.

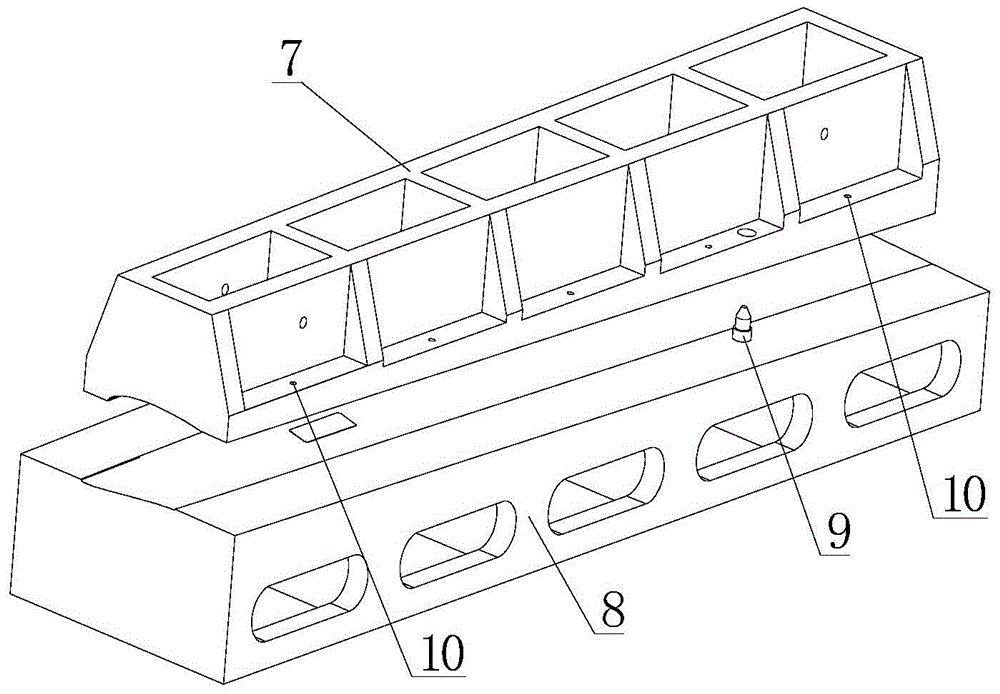

[0027] Composite material wing overall molding process equipment, adopts the auxiliary molding method of female mold and male mold; the female mold is divided into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com