A machine tool for rough and fine countersinking of inner and outer spherical surfaces and end faces of a differential case

A technology for differential gears and housings, which is applied in the field of machine tools for rough and fine spot facing of inner and outer spherical surfaces and end faces of differential gear housings, and can solve the problem of poor versatility and low processing efficiency of differential gear housings that are not suitable for multi-variety and small batch processing. Low-level problems, to achieve the effect of simple structure, low cost and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

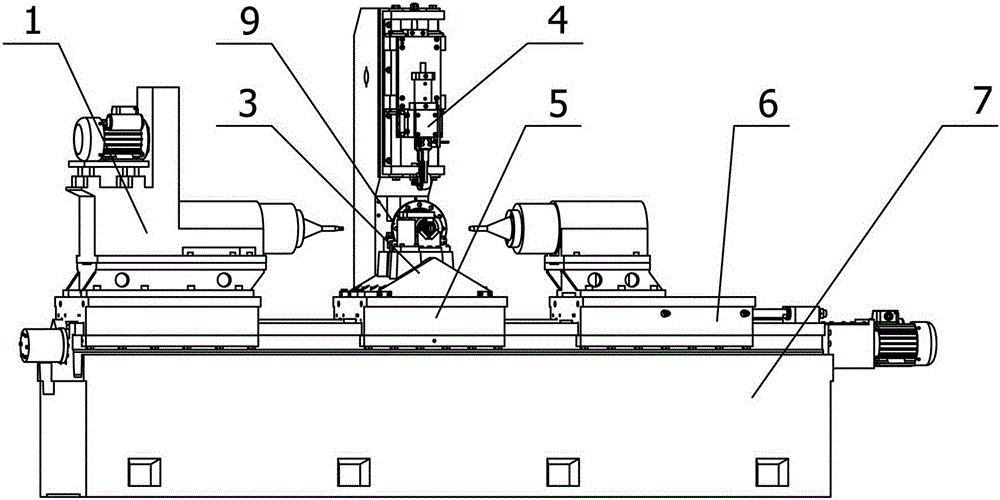

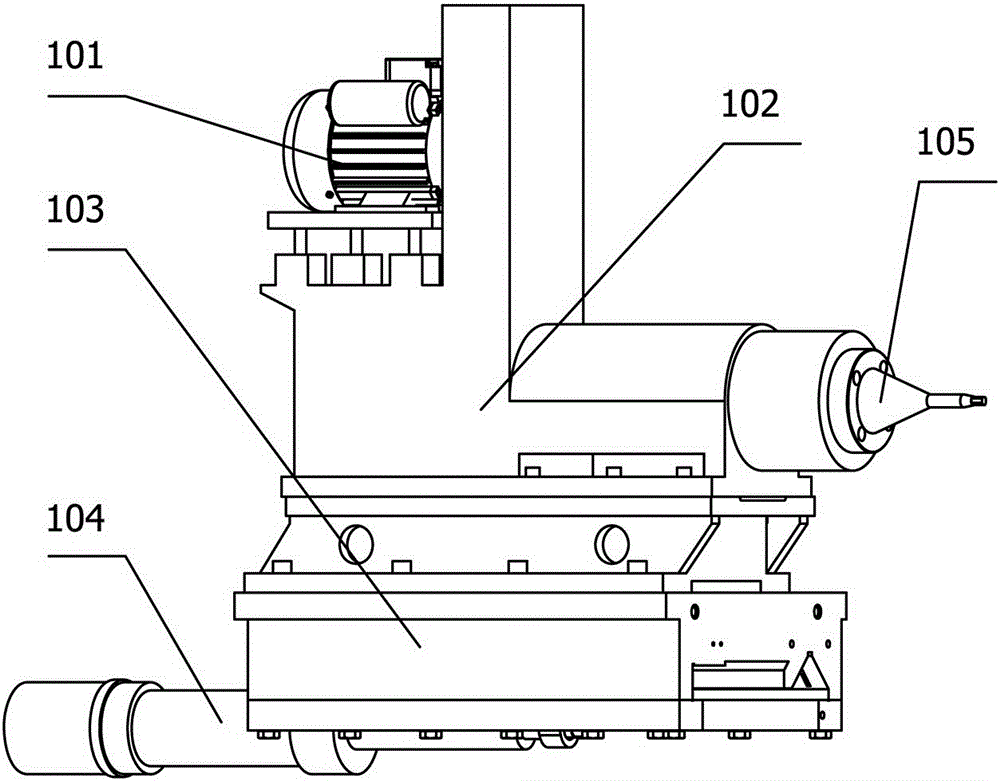

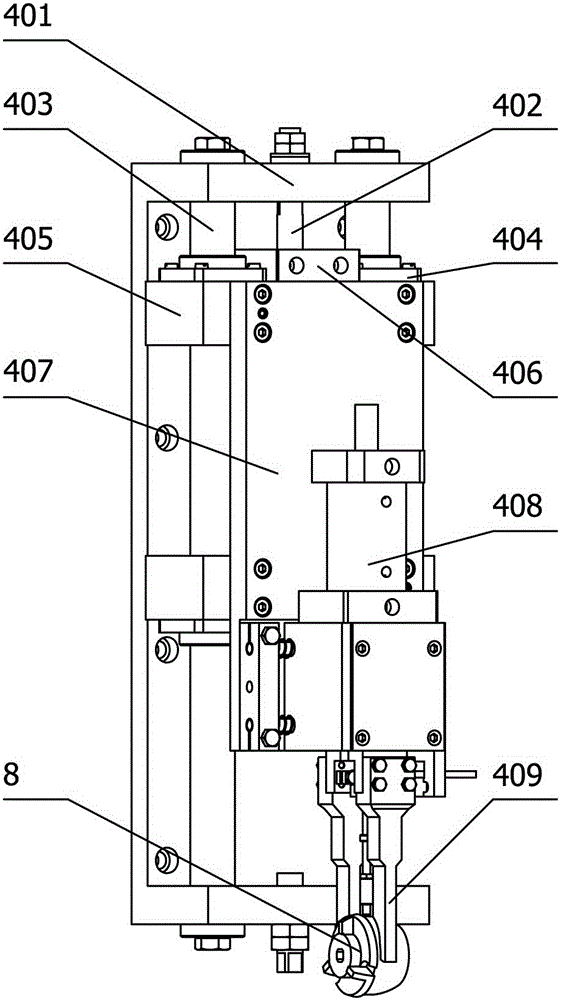

[0022] Depend on Figure 1 to Figure 5 Given, the present invention comprises lathe 7, and lathe 7 is provided with the left sliding table mechanism 1 that places on lathe 7 slide rails, middle sliding table mechanism 5, right sliding table mechanism 6, places the middle sliding table mechanism 5 rear parts The manipulator mechanism 4, the middle slide mechanism 5 is provided with a differential case clamp 3, the left slide mechanism 1 includes a left slide body 103 that can slide left and right and is fixed on the slide rail, the left slide body The right part of 103 is rotated and fixed with a left connecting rod 105, and the left connecting rod 105 is connected to the motor 101 placed on the left sliding table body 103 through the transmission box 102, and the first hydraulic oil cylinder is connected between the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com