Electrode rotation electric conduction structure

A conductive structure and electrode technology, which is applied in the field of electrode rotating conductive structures, can solve the problems of bulky equipment, failure of movable guide structures, high processing requirements, etc., and achieve the effect of ensuring the conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are described in detail below.

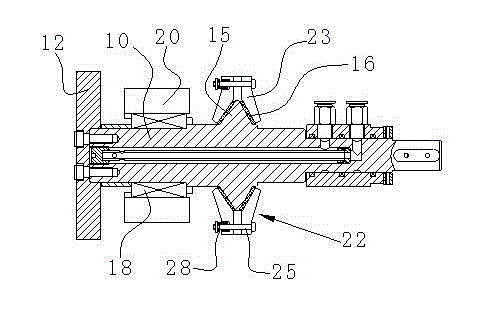

[0010] Such as figure 1 As shown, in the present invention, a seam welding machine electrode includes an electrode rotating conductive structure formed by combining the internal electrode shaft 10 and the electrode seat 20, and is connected by the support of the rolling bearing 18, so that the electrode shaft 10 is connected to the electrode seat along the shaft shoulder. The 20' ring body fits conductively.

[0011] The main structure of the electrode rotating conductive structure includes an electrode shaft 10 with an electrode wheel 12 installed at one end, and an electrode holder 20 sheathed on the electrode shaft 10. The electrode shaft 10 is provided with a trapezoidal or triangular shoulder 15 in section, so The electrode seat 29 is provided with a V-shaped annular clip body 22 adapted to surround the adjustable clip groove width surrounding the shaft shoulder 15 , and a silver sheet 16 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com