D-type multistage pump for water drainage of urban road

A technology of multi-stage pumps and roads, which is applied to parts, pumps, and pump devices of elastic fluid pumping devices. Low cost, extended service life, good sealing and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

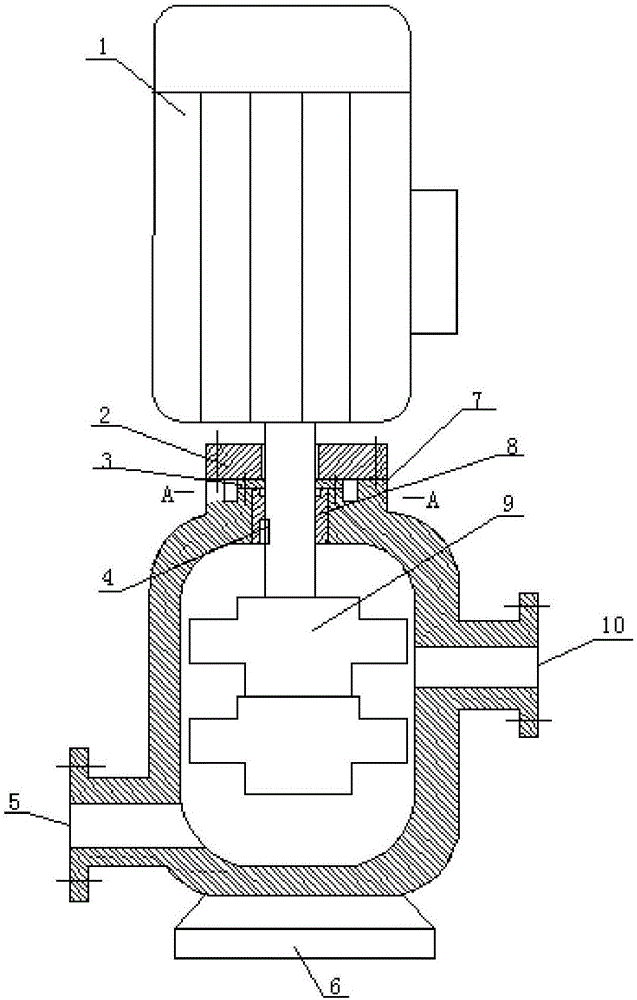

[0023] Such as Figure 1-Figure 7 The shown D-type multistage pump for urban road drainage includes a pump body 7 and a motor 1, the pump body 7 includes a water inlet port 5 and a water outlet port 10, and a combined pumping impeller 9 is arranged inside the pump body 7, so The motor 1 is vertically arranged and the rotating shaft 14 of the motor 1 passes through the upper end of the pump body 7 and communicates with the combined pumping impeller 9. The upper end of the pump body 7 is located outside the rotating shaft 14 and is fitted with an anti-corrosion and wear-resistant ring 8. The pump The upper end of the body 7 is also provided with a sealing cover 3 for sealing and an end cover 2 for fixed connection.

[0024] The pump body 7 of this embodiment is arranged vertically through the base 6 at the bottom, the combined pumping impeller 9 rotates under the drive of the rotating shaft 14, pumps water through the water inlet port 5, and discharges water through the water ou...

Embodiment 2

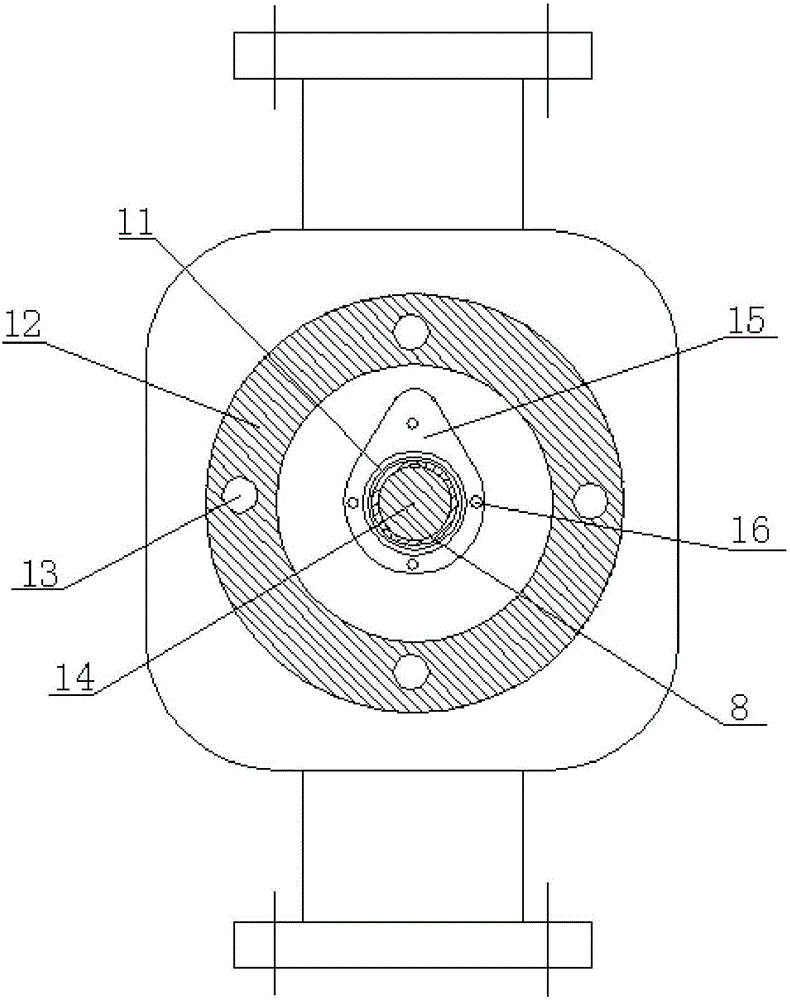

[0026] This embodiment optimizes the following structure on the basis of Embodiment 1: the upper end of the pump body 7 is provided with a flange 12, and the flange 12 is provided with a plurality of threaded holes 13, and the pump body 7 is located on the flange The inner side of 12 is also provided with a sealing cover installation platform 15, the sealing cover installation platform 15 is provided with a fixing hole 16, and the middle part of the sealing cover installation platform 15 is provided with a through hole cooperating with the rotating shaft 14, and the anti-corrosion and wear-resistant ring 8 can be The rotation is arranged in the through hole, the opening of the through hole is also provided with a sealing groove 11, the sealing cover installation platform 15 and the sealing cover 3 are fixed and sealed by bolts, and the flange plate 12 and the end cover 2 are fixed by fixing bolts Press tight.

[0027] In this embodiment, a sealing cover installation platform 1...

Embodiment 3

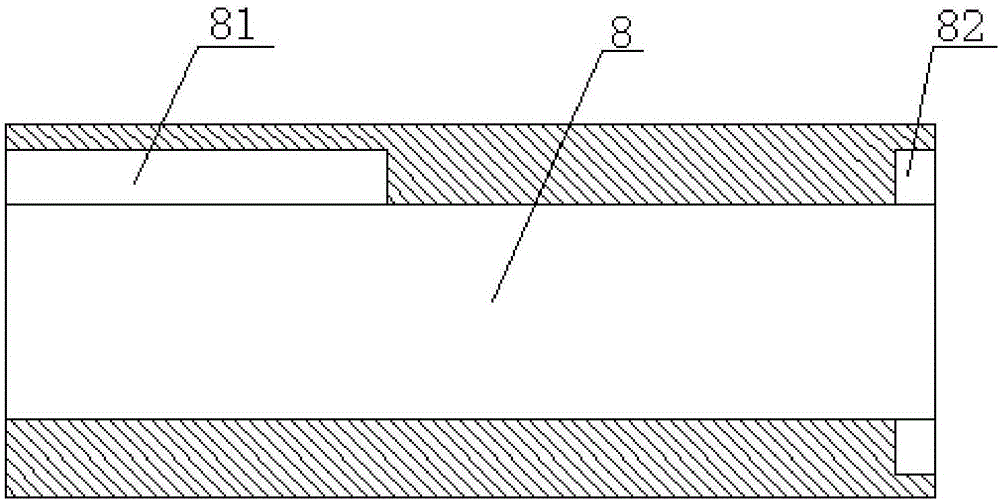

[0029] This embodiment is optimized as follows on the basis of Embodiment 1 or Embodiment 2: the inside of the anti-corrosion and wear-resistant ring 8 is provided with a keyway 81 and a gasket groove 82, and the rotating shaft 14 is provided with a The key 4, the rotating shaft 14 and the anti-corrosion and wear-resistant ring 8 are connected by a key to realize cooperative rotation.

[0030] In this embodiment, the rotating shaft 14 and the anti-corrosion and wear-resistant ring 8 are connected by a key to realize cooperative rotation, thereby ensuring that the anti-corrosion and wear-resistant ring 8 can rotate synchronously with the rotating shaft 14, avoiding leakage caused by the size change of the two, and at the same time reducing the number of rotating shafts. 14 and the pump body 7 wear each other, and the sealing gasket groove 82 can be added to the sealing ring, and is compressed by the sealing cover 3 to realize sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com