Cyclone component of natural gas dry type dedusting separator

A dry dust removal and separator technology, which is applied in the direction of devices, gas fuels, swirling devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

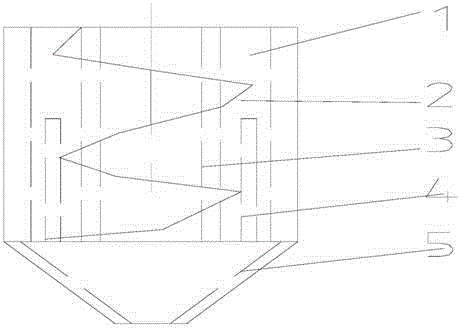

[0011] Embodiment 1 Composition of a cyclone subassembly of a natural gas dry-type dedusting separator and the functions of each component:

[0012] A cyclone subassembly of a natural gas dry-type dedusting separator, which consists of an ascending air pipe (1), a spiral guide vane (2), an inner pipe (3), an outer pipe (4), and a cone (5), and is characterized in that The ascending air pipe (1) is installed at the end of the inner pipe (3), and the outer circle of the spiral guide vane (2) has an outer helix angle of 45°-48°. The inner tube (3) is installed in the outer tube (4). The spiral guide vane (2) is welded between the inner tube (3) and the outer tube (4).

Embodiment 2

[0013] Embodiment 2 A kind of working process of the dry type dedusting cylinder of natural gas:

[0014] The gas inner pipe enters from the mouth of the ascending air pipe (1), rotates along the spiral guide vane (2) and the inner pipe (3), the gas rises from the ascending air pipe (1), and the dust is drawn to the cone (5) by centrifugal force for separation .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com