Ice cream milk paste and preparation method and soft ice cream thereof

A technology of ice cream and milk slurry, applied in frozen sweets, food science, applications, etc., can solve problems such as pipeline sterilization and coking, blockage shutdown, sugar and protein Maillard reaction, etc., to achieve smooth entrance, ideal expansion rate, and reduce beauty The effect of the Rad reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

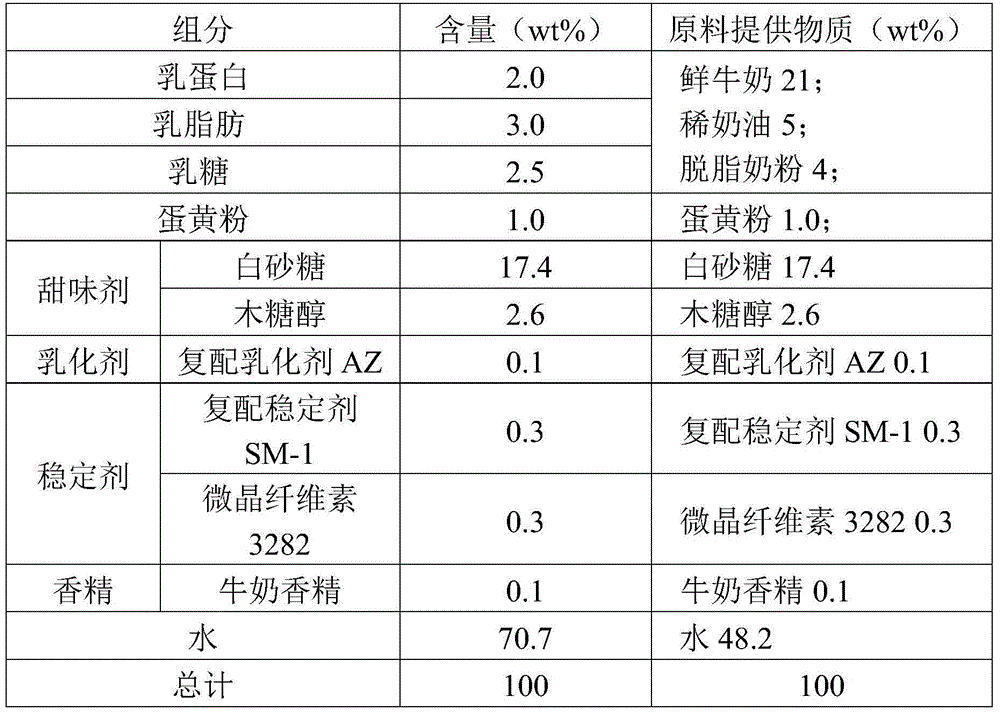

[0059] formula:

[0060]

[0061] Preparation:

[0062] (1) Mix egg yolk powder, white sugar, xylitol and water evenly, heat to 60°C, then mix evenly with microcrystalline cellulose 3282, compound emulsifier AZ and compound stabilizer SM-1, and stir for 15 minutes to obtain Feed liquid A;

[0063] (2) Cool the feed liquid A to 30°C, then add milk fat raw materials, milk protein raw materials, lactose raw materials (fresh milk, skimmed milk powder and cream) and milk essence, mix evenly, and stir for 15 minutes to obtain feed liquid B, measure The pH of the solution is now 6.5;

[0064] (3) Scraper-type ultra-high temperature instantaneous sterilization is carried out on the material liquid B, the sterilization temperature is 135 ° C, the sterilization time is 5 seconds, aseptic homogenization, the homogenization temperature is 63 ° C, the homogenization pressure is 20 MPa, and then cooled to less than 15 ℃, that is.

Embodiment 2

[0066] formula:

[0067]

[0068] Preparation:

[0069] (1) Mix egg yolk powder, white sugar and water evenly, heat to 80°C, then mix evenly with compound emulsifier AZ and compound stabilizer SM-1, and stir for 40 minutes to obtain material liquid A;

[0070] (2) Lower the temperature of feed liquid A to 63°C, then add milk fat raw materials, milk protein raw materials and lactose raw materials (fresh milk, skimmed milk powder and cream), mix well, stir for 40 minutes to obtain feed liquid B, add hexametaphosphoric acid Sodium and sodium citrate adjust the pH of the feed solution to 6.8;

[0071] (3) Scraper-type ultra-high temperature instantaneous sterilization is carried out on the material liquid B, the sterilization temperature is 137 ° C, the sterilization time is 4 seconds, sterile homogenization, the homogenization temperature is 60 ° C, the homogenization pressure is 25 MPa, and then cooled to less than 30 ℃, that is.

Embodiment 3

[0073] formula:

[0074]

[0075] Preparation:

[0076] (1) Mix egg yolk powder, white sugar, erythritol and water evenly, heat to 70°C, then mix evenly with microcrystalline cellulose 3282, compound emulsifier AZ and compound stabilizer SM-1, stir for 30 minutes, Obtain feed liquid A;

[0077] (2) Cool the feed liquid A to 55°C, then add milk fat raw materials, milk protein raw materials and lactose raw materials (fresh milk, skimmed milk powder and cream), mix well, stir for 30 minutes to obtain feed liquid B, add sodium citrate Adjust the pH of the feed solution to 6.6;

[0078] (3) Scraper-type ultra-high temperature instantaneous sterilization is performed on the material liquid B, the sterilization temperature is 140 ° C, the time is 3 seconds, sterile homogenization, the homogenization temperature is 55 ° C, the homogenization pressure is 20 MPa, and then cooled to less than 15 ° C , that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com