White, opaque, beta-spodumene/rutile glass-ceramics,articles comprising the same,and methods for making the same

A spodumene and glass technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as damage to the internal/electronic components of portable computing devices, user dissatisfaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0140] The following examples illustrate some of the advantages and characteristics of the invention and are not intended to limit the invention thereto.

[0141] Since the sum of the individual components is about or very close to 100, for all practical purposes the reported values are to be understood as expressing mole percent. The actual crystallizable glass batch components may comprise any material, including oxides or other compounds, which, when melted together with the other batch components, will convert to the desired oxides in the proper proportions.

[0142]

[0143]

[0144] Examples 1-8: Exemplary crystallizable glasses listed in Table I were prepared in platinum crucibles using raw material batches formulated to yield 1000 grams of crystallizable glass after melting and fining. Each crucible containing the formulated raw material batch is placed in a furnace preheated to 1575-1650°C, the formulated raw material batch is melted and clarified to produce m...

Embodiment A

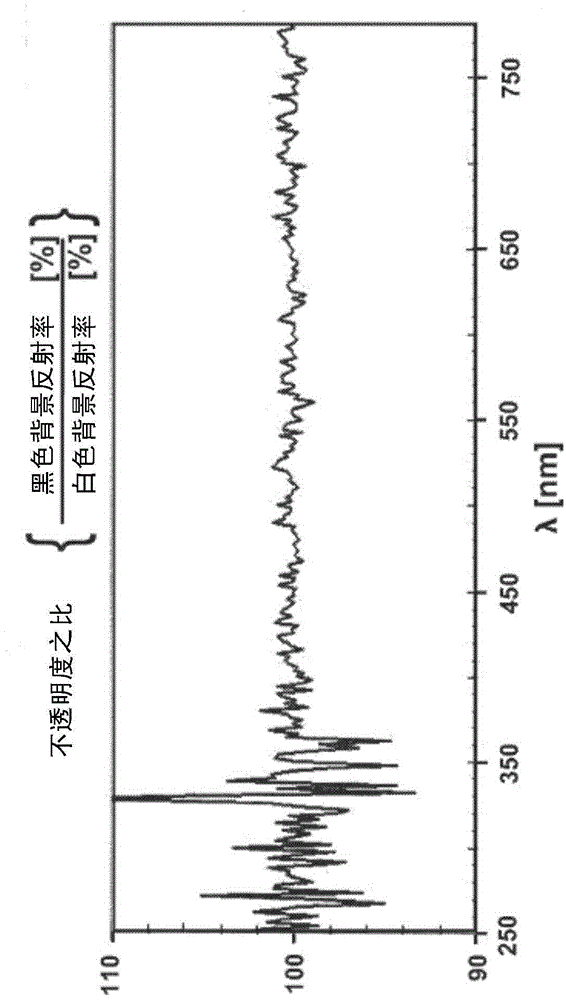

[0153] Example A: Nucleation (heating at 5°C / min to 780°C and holding at 780°C for 2 hours) and crystallization (heating at 5°C / min from 780°C to 975°C and holding at 975°C for 4 hours) The cake of the crystallizable glass in Example 1 of Table I was heat-treated to obtain a glass-ceramic. Glass-ceramic samples 50 x 50 cm square and 0.8 mm thick were produced with optically polished surfaces prepared. The opacity of the sample was determined by measuring the spectral reflectance of the polished sample using a black and white background behind the sample. The opacity of the sample is the ratio of the reflectance of the sample measured by the above two methods; a value of 1 means 100% opacity. figure 1 Showing the opacity exhibited by this example, it can be seen that in the wavelength range of 250-750 nm, the opacity values exceed 90% opacity.

Embodiment B-D

[0154] Examples B-D: Three cakes of the crystallizable glass in Example 1 of Table I were heat-treated using different crystallization conditions to obtain glass-ceramics. Each cake was nucleated in the same manner as described above in Example 1 (heating at 5°C / min to 780°C and holding at 780°C for 2 hours), but each cake was listed in Table II Crystallization at the different temperatures indicated for 4 hours (heating from 780°C to Tc[°C] at 5°C / min and holding at Tc[°C] for 4 hours). As determined by XRD analysis, the resulting glass-ceramic exhibited a combination of crystalline phases comprising a solid solution of β-spodumene as a major crystalline phase and a secondary crystalline phase including rutile. The amount of crystalline phase and residual glass (in % by weight) in each sample was determined using the Rietveld analysis method known to those skilled in the art, as described, for example, in Taylor, J.C. ( 2004, 2003, & 2001), "Rietveld Made Easy: A Practical G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com