Azimuth friction free towing point

A technology of towing points and towing winches, applied in the direction of tugboats, towing/push equipment, ship parts, etc., can solve the wear and tear of towing cables, increase the cost of repairing, maintenance and replacement of towing cables or towing points, and the average time of failure of towing cable connections Minimize problems such as maintaining complete control, effective and flexible deployment, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

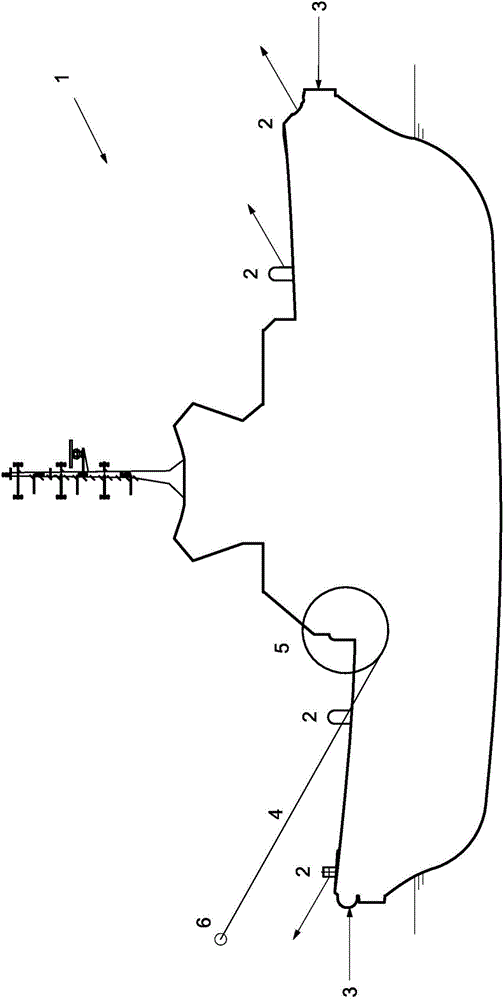

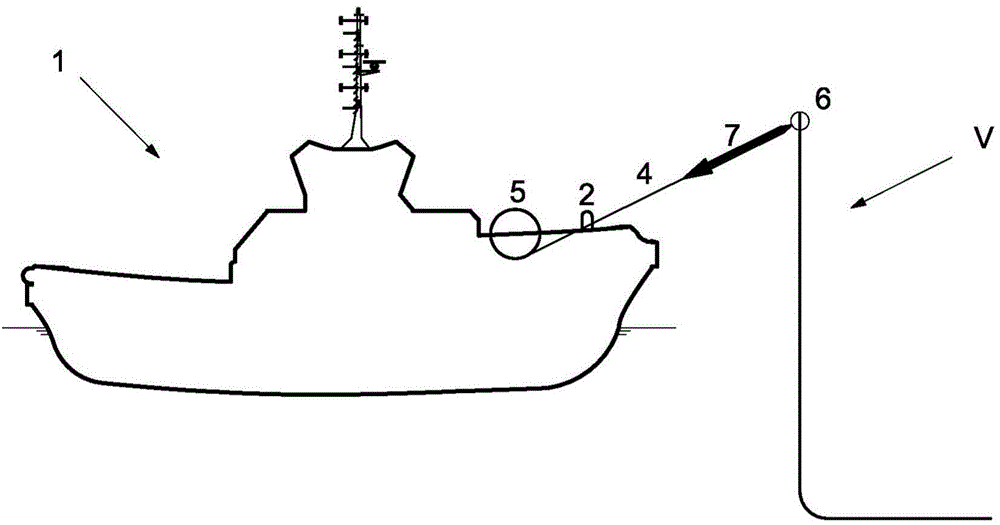

[0032] In this specification, exemplary embodiments of the tug and the towing point of the present disclosure are shown by way of example only. These should never be considered as limiting the scope of the present disclosure. The drawings are only schematic. In these drawings, the same or similar reference numerals will be used for the same or similar components or features.

[0033] In this specification, vertical and horizontal in their usual meanings refer to plane or direction, and the direction related to a vessel or tugboat defined by horizontal or vertical is when the vessel or vessel is in a floating position and in a normal stable position. The position is used, unless otherwise specifically limited.

[0034] In this specification, substantially frictionless must be understood to include, but not limited to, substantially lower friction in towing cables and towing points in known towing operations for the same vessel and tug. Substantially frictionless can be understood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com