A three-degree-of-freedom motion motor with liquid-mass suspension bionic electromagnetic drive

An electromagnetic drive, suspension technology, applied in the direction of connection with control/drive circuit, electric components, magnetic circuit rotating parts, etc., can solve the problems of difficult control accuracy, complex motor structure, large volume, etc., and achieve easy miniaturization and integration. simplification of mechanical system design and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

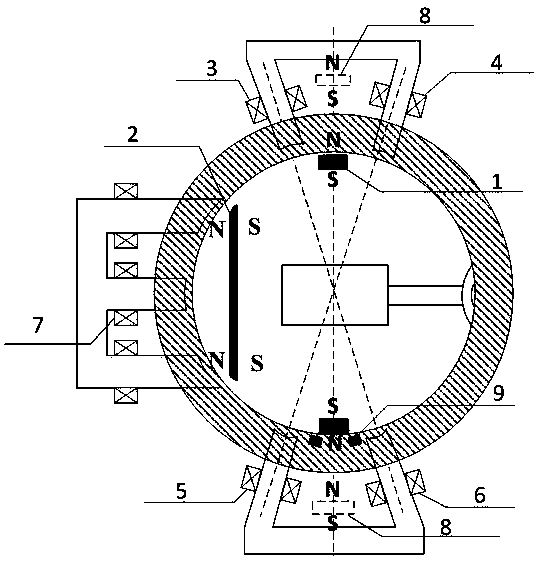

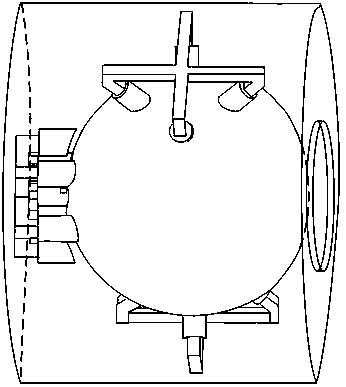

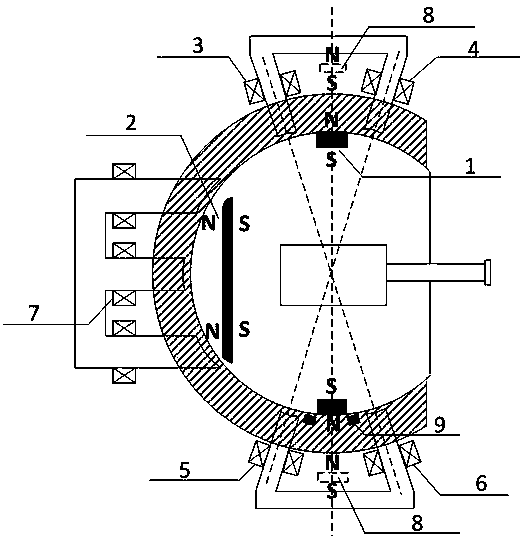

[0028] see Figure 1-Figure 7 , The liquid suspension bionic electromagnetic drive three-degree-of-freedom motion motor includes: a rotor, a stator and a housing part, and is characterized in that: the motor adopts an embedded or output shaft structure; the rotor is a hollow spherical shell, and the hollow part of the rotor is A wireless transmission device and a visual image acquisition device can be placed; a pair of permanent magnets 1 are fixed on at least one diameter direction on the inner surface of the rotor shell; A number of magnetic pole iron cores are fixed on the pole iron cores, and the stator coils 3, 4, 5, and 6 are wound on the magnetic pole iron cores. The rotor suspension is sealed between the stators, that is, liquid fluid with suitable damping, so that the rotor is supported by liquid suspension; after inputting a current of a specific direction and amplitude to the stator coils 3, 4, 5, and 6 in the vertical position, it will generate Deflection torque, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com