Graphene supported two-dimensional branched platinum nanometer electrocatalyst, and preparation method and application thereof

An electrocatalyst and graphene technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem that the platinum crystal surface cannot be effectively used, and achieve the effect of easy control and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

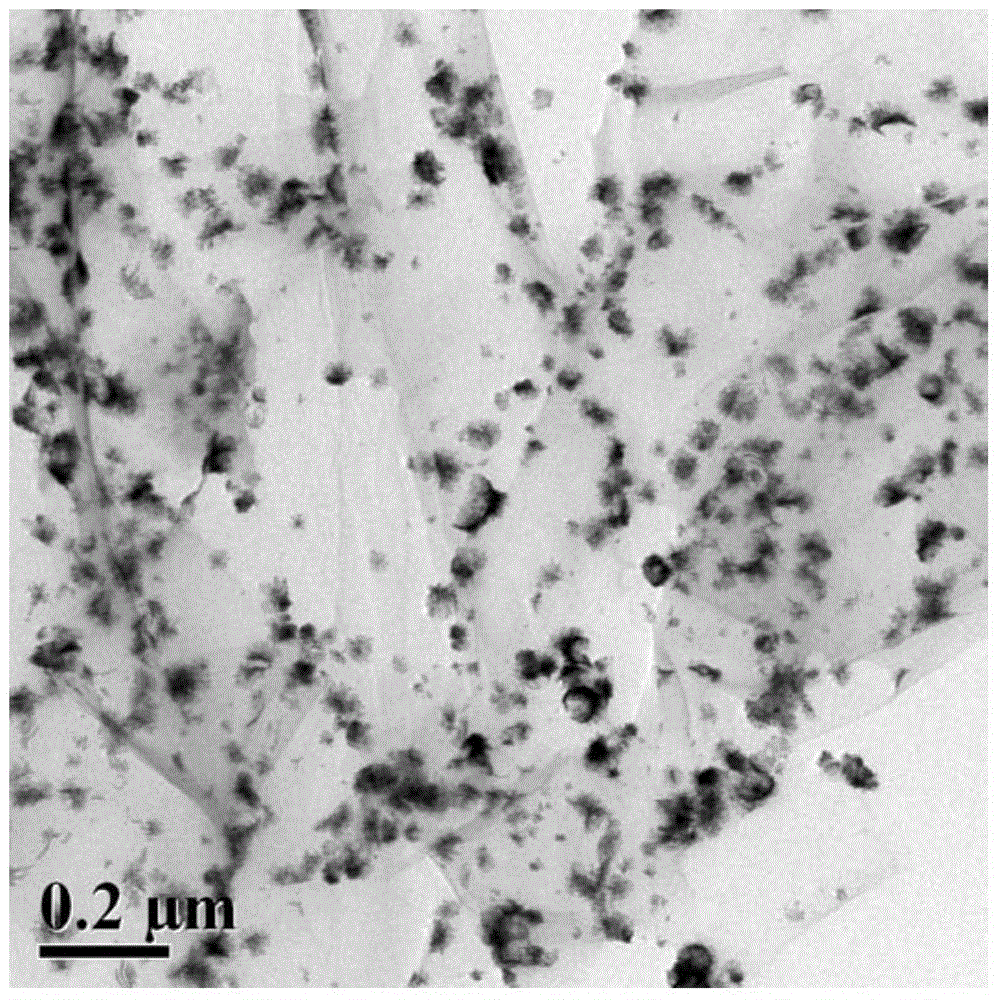

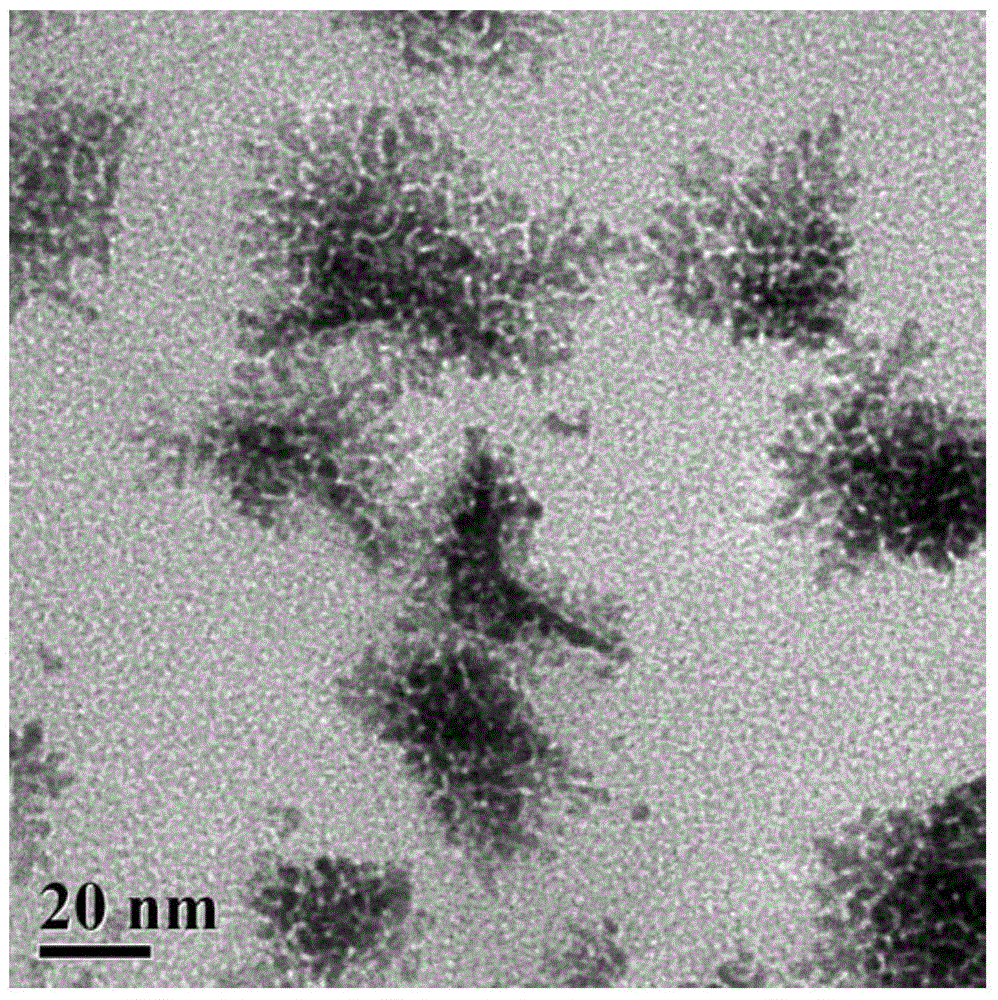

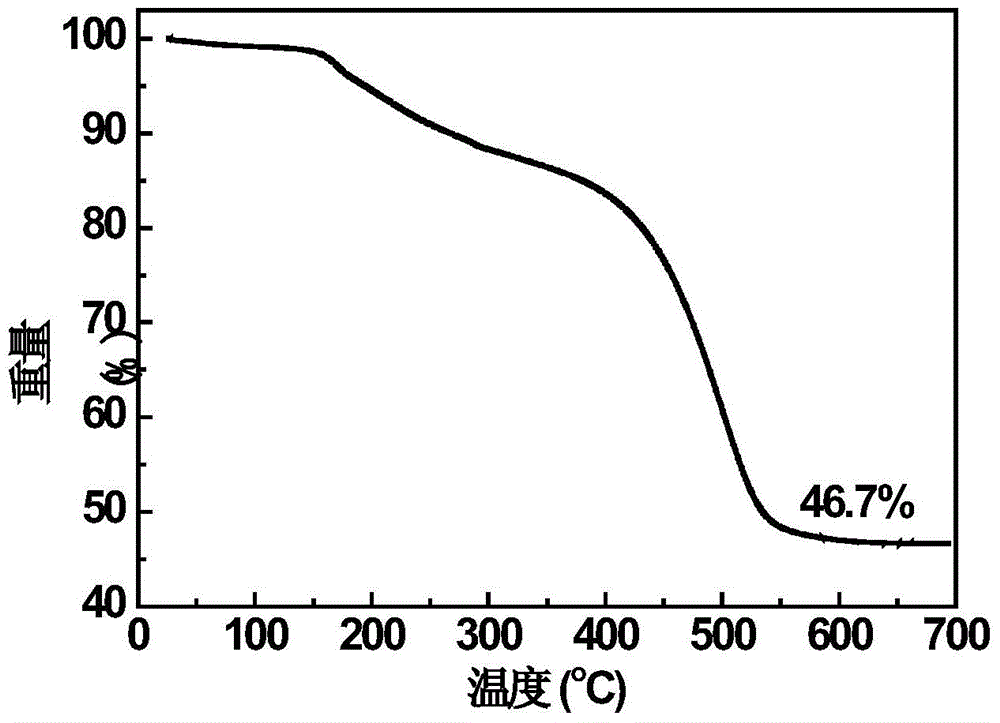

[0040]Dissolve 15.80 mg of distearoylphosphatidylcholine (1,2-dioctadecanoyl-sn-glycero-3-phosphocholine) and 7.73 mg of cholesterol in 20 mL of chloroform, and rotary evaporate the solution at 30 °C to prepare multilayered lipids Body membrane, after drying, add 20mL water and 527.1mg ascorbic acid, transfer the mixture to a liposome extruder after hydration at 65°C for 1 hour, select a porous organic filter membrane with a pore size of 200nm, use nitrogen as the pressurized gas, and pressurize at 65°C Squeeze the mixture through a porous organic filter membrane 10 times at °C to obtain 20 mL of an aqueous solution of unilamellar liposomes (1 mM) containing a reducing agent. Add 12.6mg of commercial graphene into the above-mentioned 16mL monolayer liposome aqueous solution containing a reducing agent, ultrasonically disperse evenly, and then add 4.62mL of 20mmol / L K 2 PtCl 4 aqueous solution and 11.38mL H 2 O, the reaction was stirred at 25°C for 3 hours. The reacted mixtu...

Embodiment 2

[0047] Example 2: Concentration of monolamellar liposomes

[0048] Dissolve 39.51mg of distearoylphosphatidylcholine and 19.34mg of cholesterol in 10mL of chloroform, and evaporate the solution at 30°C to prepare a multilayer liposome membrane. After drying, add 10mL of water and 263.5mg of ascorbic acid, 65 After hydration at ℃ for 1 hour, transfer the mixture to a liposome extruder, select a porous organic filter membrane with a pore size of 200 nm, use nitrogen as the pressurized gas, and squeeze the mixture through the porous organic filter membrane 10 times at 65 °C to obtain 10 mL Aqueous solution (5 mM) of unilamellar liposomes containing reducing agent. Add 12.4 mg of commercial graphene to the above-mentioned 8 mL of monolayer liposome aqueous solution containing a reducing agent, ultrasonically disperse evenly, and then add 4.62 mL of 20 mmol / L K 2 PtCl 4 aqueous solution and 3.38mL H 2 O, the reaction was stirred at 25°C for 3 hours. The reacted mixture was tran...

Embodiment 3

[0053] Example 3: The concentration of phospholipids is different, and the ratio of cholesterol to phospholipids is different

[0054] Dissolve 1976mg of distearoylphosphatidylcholine and 19.34mg of cholesterol into 10mL of chloroform, and rotary evaporate the solution at 30°C to prepare a multilayer liposome membrane. After drying, add 10mL of water and 263.5mg of ascorbic acid, and heat After hydration for 1 hour, transfer the mixture to a liposome extruder, select a porous organic filter membrane with a pore size of 200 nm, use nitrogen as the pressurized gas, and squeeze the mixture through the porous organic filter membrane 10 times at 65°C to obtain 10 mL of Aqueous solution of unilamellar liposomes containing reducing agent. Add 12.4 mg of commercial graphene to the above-mentioned 8 mL of monolayer liposome aqueous solution containing a reducing agent, ultrasonically disperse evenly, and then add 4.62 mL of 20 mmol / L K 2 PtCl 4 aqueous solution and 3.38mL H 2 O, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com