Semi-automatic exchange equipment for electrical testing and its testing method

An electrical testing, semi-automatic technology, applied in the testing field, can solve the problems of high false detection rate, high testing cost, poor interchangeability, etc., and achieve the effect of reducing visual error, improving testing efficiency, and reducing manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

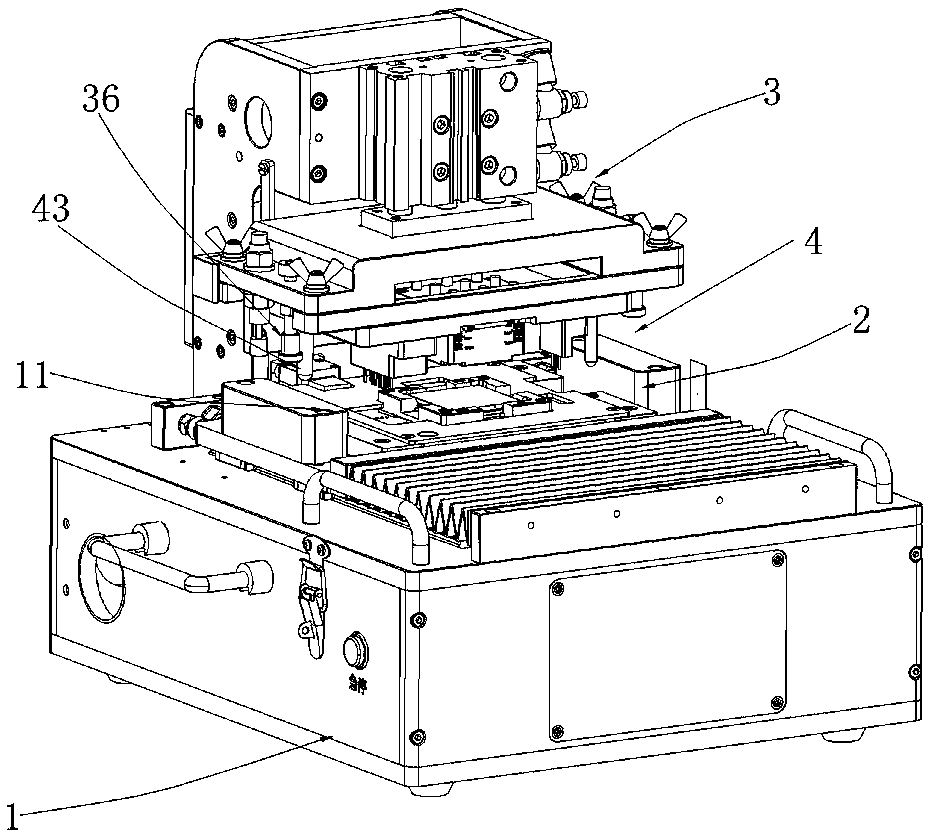

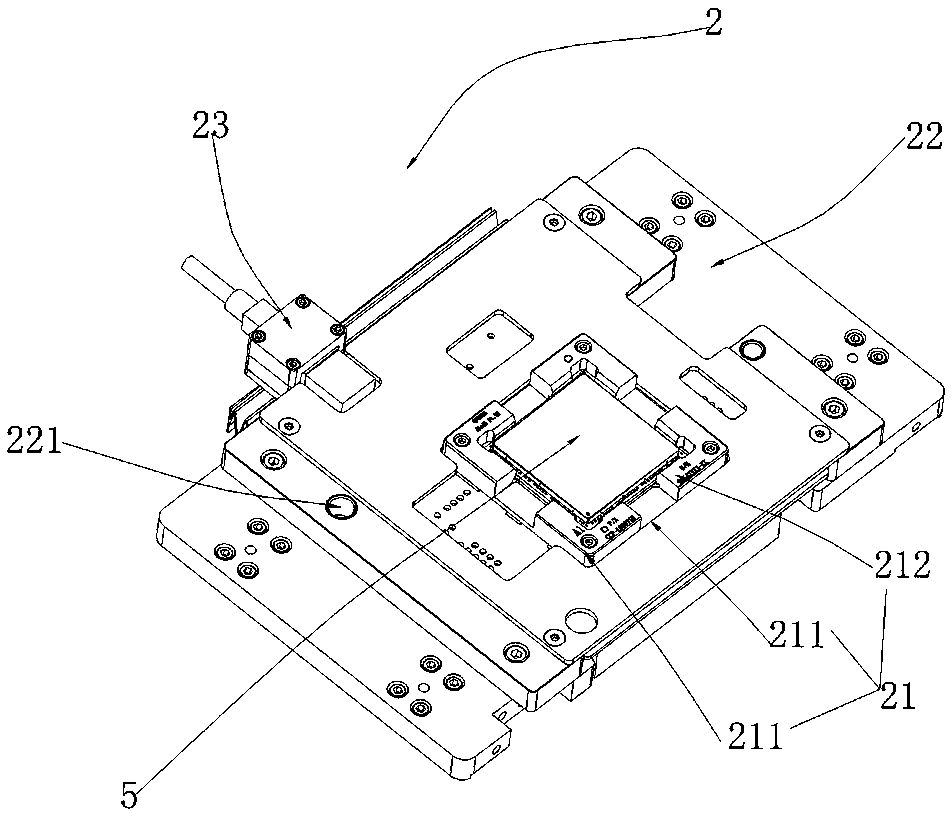

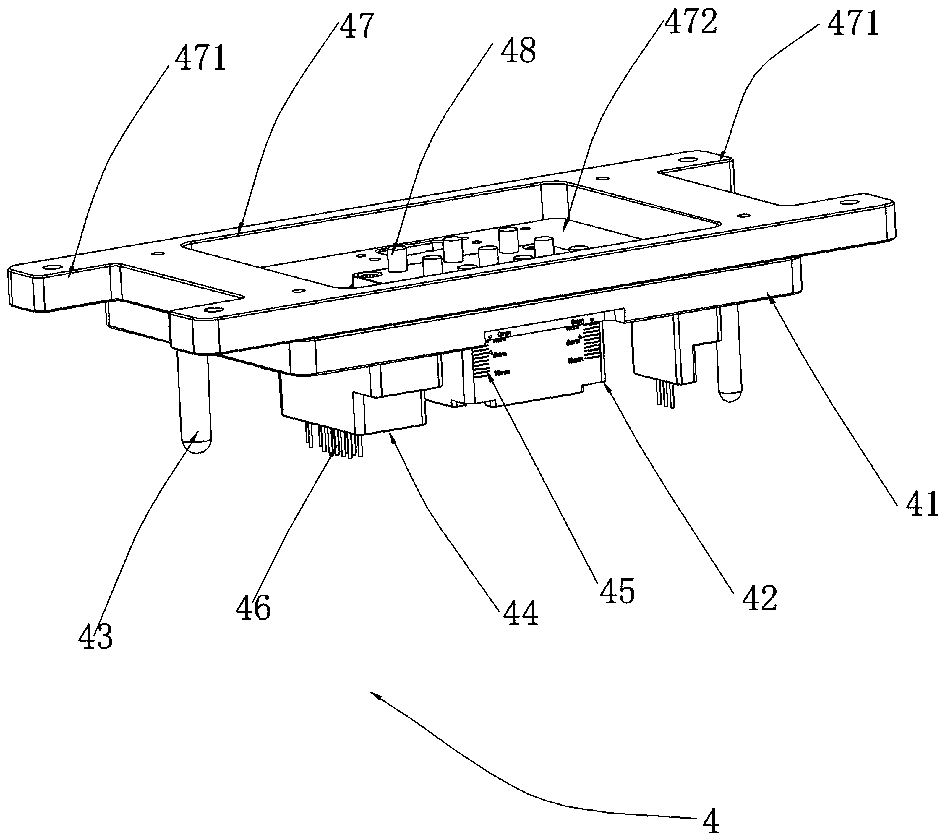

[0046] see Figure 1-4 , the semi-automatic exchange equipment for electrical testing provided by the present invention includes a chassis 1, a quick-change product mechanism 2 for placing products of different shapes, a quick-change upper needle plate mechanism 3 for switching corresponding corresponding needle plates according to different products, and a needle plate mechanism 3 according to different products. Different heights of the product switch and replace the pressing block and monitor whether the pressing block is in place. The stroke can monitor the pressing block mechanism 4; the quick-change product mechanism 2 and the quick-change upper needle plate mechanism 3 are installed on the chassis 1, and the stroke can monitor the pressing block mechanism 4 It is installed at the bottom of the quick-change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com