High-pile wharf horizontal bearing capacity and static-dynamic characteristic in-situ overall detecting method

A technology of horizontal bearing capacity and high-pile wharf, applied in elastic testing, mechanical solid deformation measurement, electric/magnetic solid deformation measurement, etc., can solve the problem that the decline of high-pile wharf bearing capacity cannot be accurately determined, and achieve easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The detection method of the present embodiment comprises the following steps:

[0045] 1. Determination of the basic damping characteristics of the wharf structure

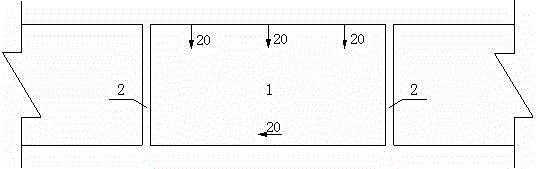

[0046] Such as figure 1 As shown, a wharf test structure section 1 between the wharf structure seams 2 is selected, and four inertial velocity sensors 20 are installed on its panel to detect the dynamic characteristics of the structure under the action of natural environment such as tide and wind or water flow. Among them, three are installed in landscape and one is installed in portrait.

[0047] 2. Install tension and force system and apply horizontal load

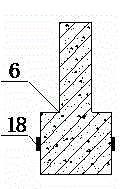

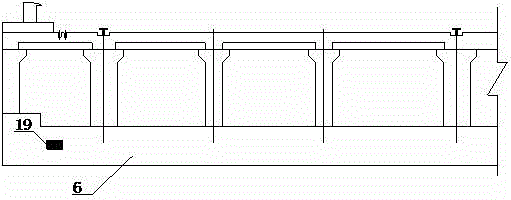

[0048] Such as figure 2 and image 3 As shown, in order to apply a horizontal longitudinal load along the longitudinal direction of the wharf and a horizontal transverse load along the horizontal direction of the wharf respectively, a tension and force system is installed between the two structural sections of the wharf, including tension system 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com