Method and system for detecting elliptical hole group based on maximum inscribed circle

A technology of maximum inscribed circle and detection method, applied in measuring devices, instruments, optical devices, etc., can solve the problems of low precision, high cost, large time consumption, etc., and achieve the effect of high precision and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

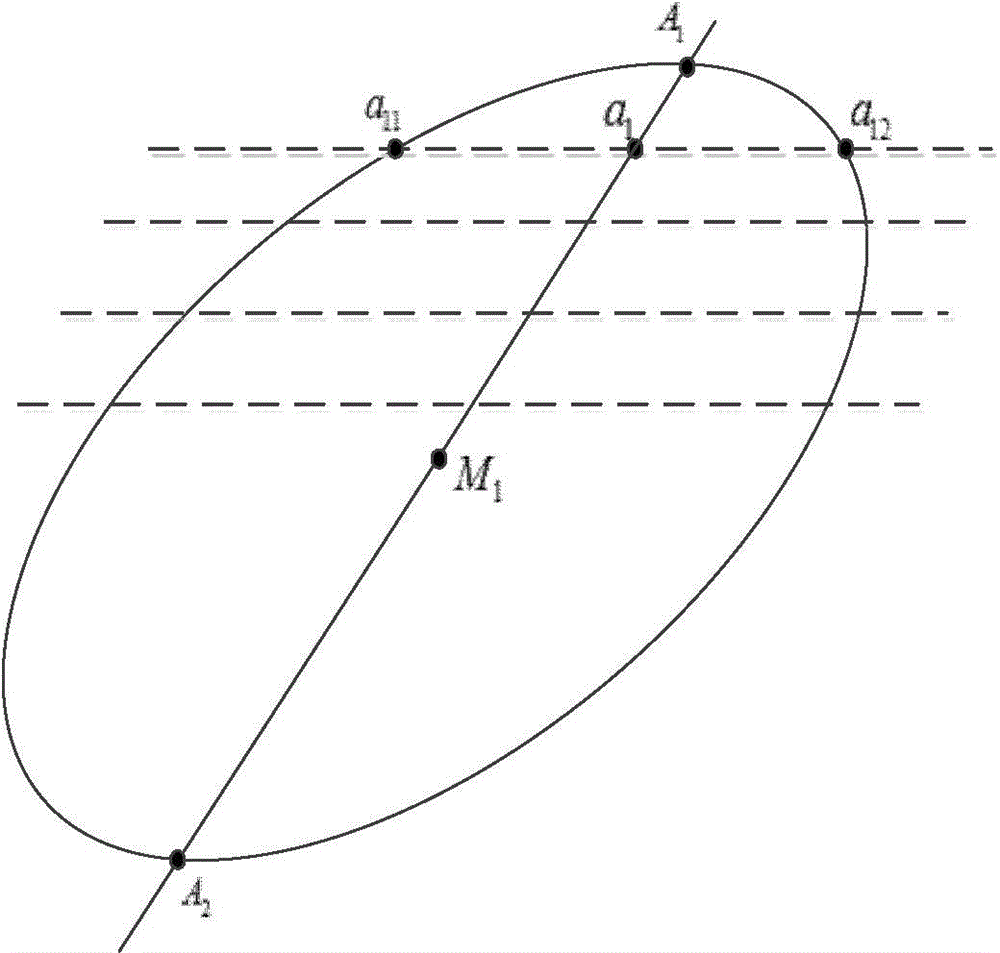

[0029] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Such as figure 1 The flowchart of the detection method of the present invention shown, a kind of elliptical hole group detection method based on the largest inscribed circle, comprises the following steps:

[0031] (1) Collect the workpiece image information.

[0032] (2) Perform image preprocessing on the collected image information. Due to the presence of noise in the image sampling process, this will cause certain errors in the accuracy and time-consuming of the later detection of the part image. Therefore, it is necessary to minimize the noise before performing relevant dimension measurements on the image sample of the hole set workpiece. In order to reduce the noise, the combination of median filtering method and morphological opening operation to remove small targets is adopted. Secondly, edge detection is performed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com