Magnetic material sintering elevator furnace of optimization circulation system

A circulation system and magnetic material technology, applied in the direction of bell-type furnaces, furnaces, furnace cooling, etc., can solve the problem that the internal quality and appearance quality of products do not meet the expected goals, the physical and chemical reactions do not meet the product performance requirements, and the expansion of enterprise equipment Invest in issues such as labor intensity of employees to achieve reasonable and controllable oxygen content, reduce anisotropy constants and expansion constants, and balance the pressure in the kiln

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

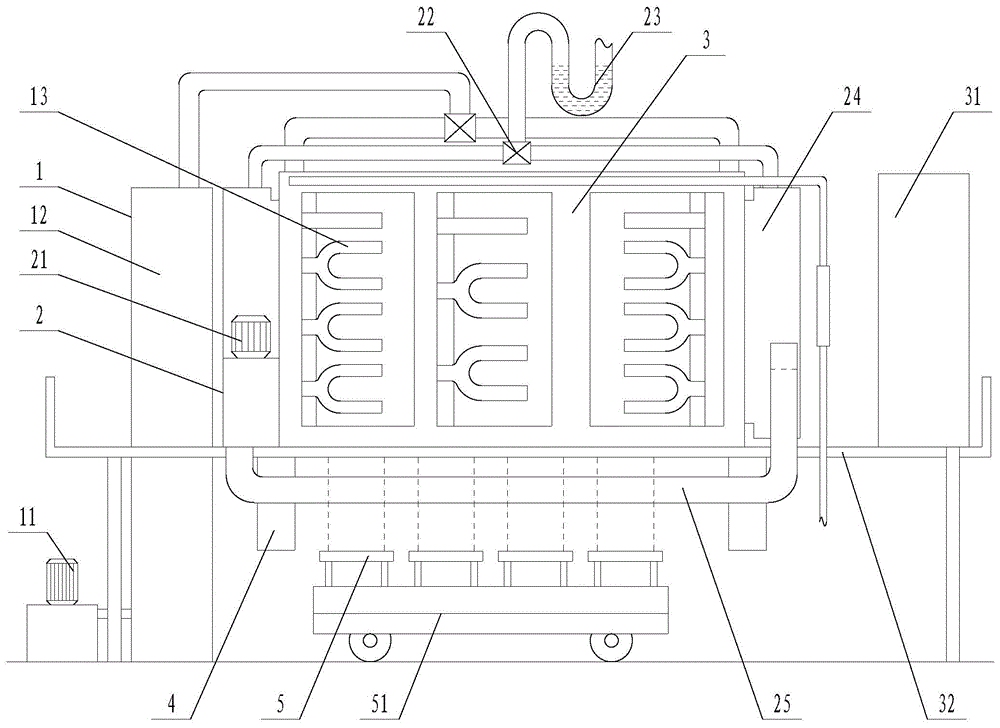

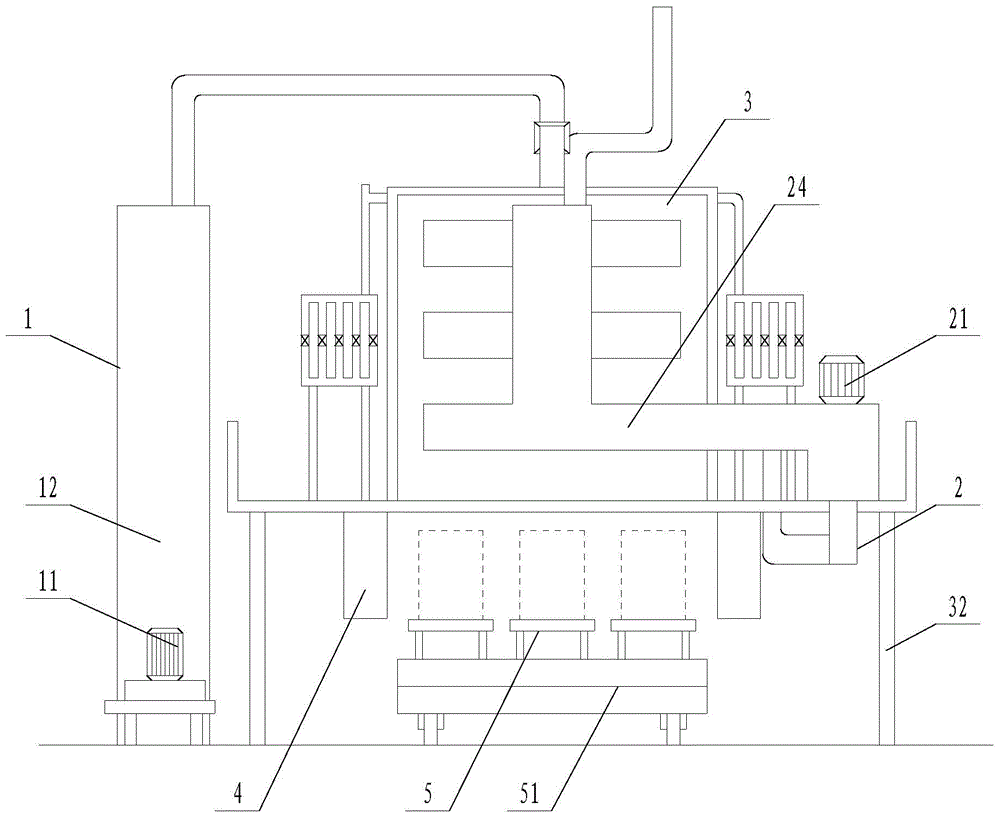

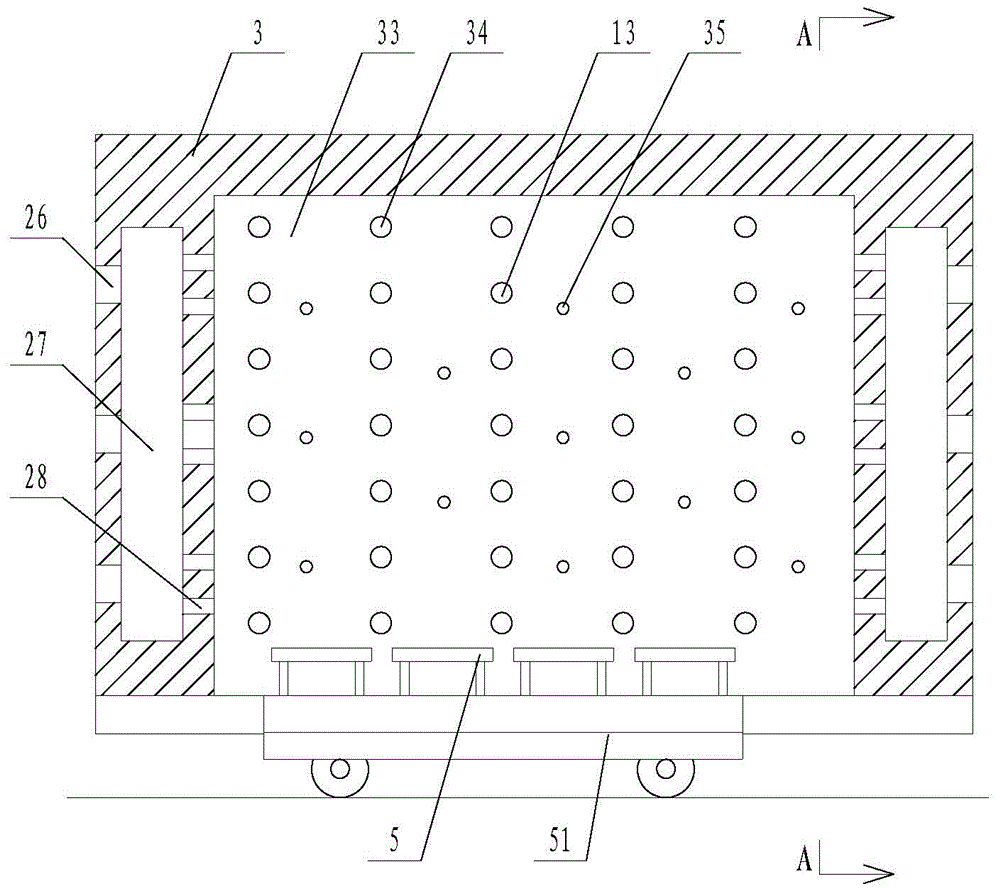

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] Such as figure 1 , figure 2 As shown, the bell jar furnace for firing magnetic materials with an optimized circulation system includes a furnace body 3, the furnace body 3 is supported by a bracket 32, the bottom of the furnace body 3 is provided with a lifting system 4, and the bottom of the furnace body 3 is provided with a firing plate 5. The plate 5 is placed on the kiln car 51; the lifting system 4 controls the setter plate 5; the left and right sides of the furnace body 3 are provided with a cooling circulation system A2, and the cooling circulation system A2 includes a circulating fan A21, and the left and right sides of the furnace body 3 are respectively provided with There is a bellows 24, and the circulation blower A21 is connected with the furnace 33 through the ventilation pipe 25 and the bellows 24; the top of the furnace 33 is provided with an exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com