Volute-free centrifugal fan with arc pillars

A centrifugal fan without a volute, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc. It can solve the problems of no conversion of kinetic energy at the outlet of the impeller, low static pressure efficiency, loss, etc., and achieve small cutting movement resistance , smooth cutting and significant static pressure gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

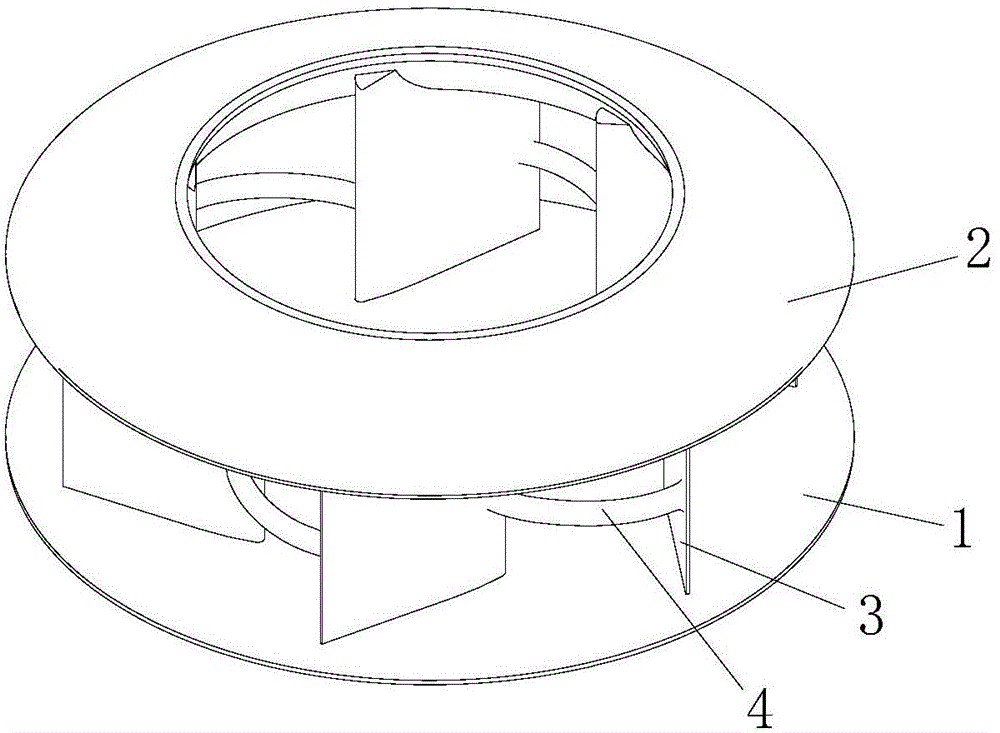

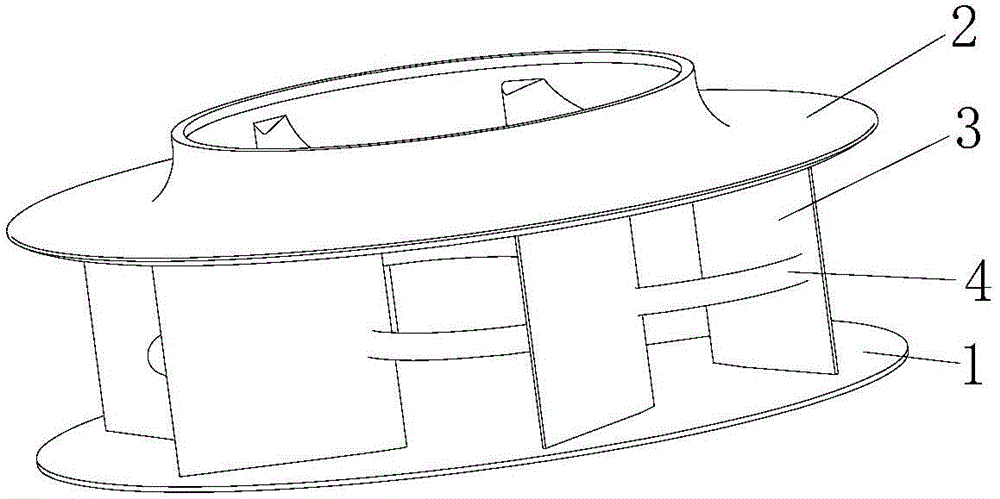

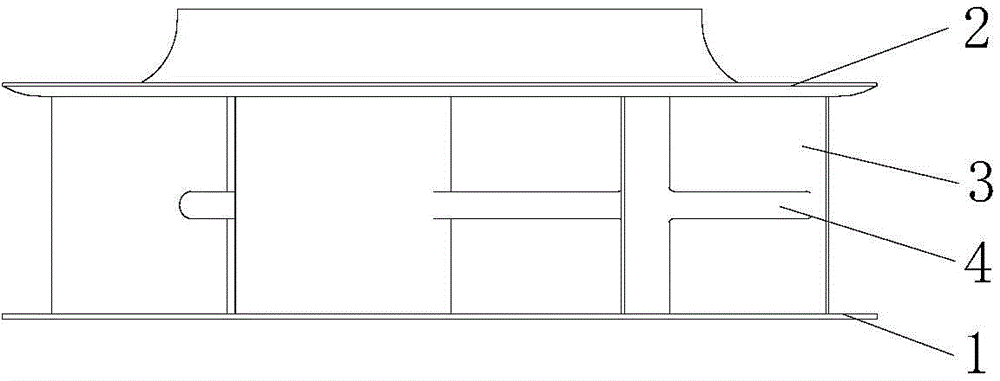

[0022] Embodiment one: if Figure 1~4 As shown, this embodiment includes a rotating shaft (not shown), and a wheel disc 1 and a wheel cover 2 that are positioned on the rotating shaft and cooperate with each other. The wheel cover 2 is an arc-shaped wheel cover. Six blades 3 are installed, and the blades 3 are backward airfoil blades, and an outlet diffuser edge is arranged between the blades 3 and the disc 1 . An arc pillar 4 is also installed between any two adjacent blades 3, and the arc pillar 4 is a strip arc, and one end of the arc pillar 4 is fixed with the blade surface of the previous blade, and the other end is connected with the rear blade. The blade surfaces of the blades are fixed; the arc-shaped pillars 4 are located on the same plane, and the plane is perpendicular to the rotation axis. Wherein, the outlet installation angle of the arc-shaped pillar 4 is 168°.

[0023] Through the CFX fluid dynamics simulation software, the flow rate of this embodiment is 9372...

Embodiment 2

[0024] Embodiment 2: The only difference from Embodiment 1 is that the outlet installation angle of the arc-shaped support 4 is 160°.

[0025] Through the CFX fluid dynamics simulation software, this embodiment obtains the optimal static pressure efficiency of 64.35% when the flow rate is 9372.39m3 / h and the static pressure is 753.26Pa.

Embodiment 3

[0026] Embodiment 3: The only difference from Embodiment 1 is that the outlet installation angle of the arc-shaped support 4 is 172°.

[0027] Through the CFX fluid dynamics simulation software, in this embodiment, when the flow rate is 9372.53m3 / h and the static pressure is 758.18Pa, the optimal static pressure efficiency is 64.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com